Search the Community

Showing results for tags 'tray'.

-

So I'm finally starting on the ground floor buildup. It's 50mm poured screed on 150mm insulation (100mm PIR/50mm graphite EPS). I'm unsure of how the tray works in this situation... The tray is (IIRC) about 45mm thick, so I'll need to set it on ply/OSB/cementboard to get the levels right. That bit's OK. But how does said underlayer sit on the PIR, is it just bonded down or should it extend under the screed edge too, to "key" it in? It's in a corner so two walls and two floor edges. ta

-

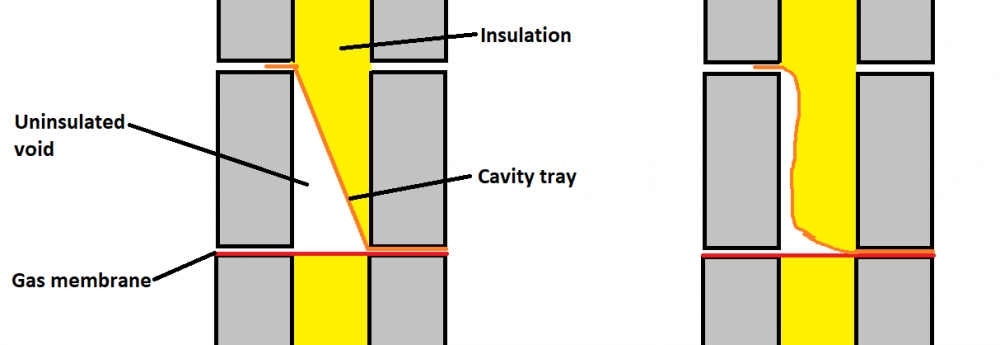

Cavity trays made using DPC roll are often shown simplistically crossing the cavity at an angle from their top on the inner leaf to bottom on the outer leaf. In reality, even if you try to run the DPC material down the inner leaf before crossing the cavity, you will still create a void behind the cavity tray that will end up uninsulated: Is there a way to insulate this void or is it a matter of trying to keep it as small as possible? Preformed corners and stop ends all seem to adopt the shape on the left and so will create quite a significant cold bridge. I'm using blown bead insulation. There is no route for the beads to get between the gas membrane and cavity tray. Also I wouldn't want the pressure of the bead blowing to dislodge the cavity tray.

- 8 replies

-

- cavity insulation

- dpc

-

(and 1 more)

Tagged with:

-

Our en-suite and main bathroom will both be wet rooms. I have identified the wet room formers for the 2 shower areas, they are 22mm thick, but for reasons of budget (lack of) I am not buying them yet. I do however want to floor most of the rooms. So what 22mm thick floor boarding for a wet room, suspended on Posijoists at 600mm centres? Is it as simple as P5 chipboard, or something more exotic?