Search the Community

Showing results for tags 'soundproofing'.

-

Ive ended up with surplus EPS insulation - 25mm thick and now need to buy some soundproofing to fill stud work walls and first floor ceiling. Can I use up the EPS as sound proofing layer (even a double layer) instead?

-

Hi, I am just looking for some advice and wanted to see if anyone had any success in soundproofing their house from neighbours in a Semi Detached house. I am not the most savvy at Construction and Building work so I’ll try put as much detail as I can! I have recently moved into a Semi detached property and am experiencing a lot of intrusive noise from our neighbours. Couple with 3 young kids who run around and scream like maniacs. Constantly hear them running up and down their stairs and on the landing. Can also hear everything the family do in their kitchen as it backs onto our lounge. (Cupboards closing, appliances, switches/sockets being used). Can hear all of this clear as day as if it’s a hollow wall separating us. Can also hear them walking up and down the stairs and slamming doors. (Hard to tell whether they are slamming and stomping or if it’s just poor insulation or work between the properties). We have a breeze-block party wall with a layer of plasterboard on our side which I believe is Dot and Dab. Downstairs we have a lounge and kitchen along the party wall with the stairs going up through the middle separating the two. Then upstairs we have our landing and two bedrooms along the party wall. So currently we are going to look at getting the lounge, bedrooms and landing done first and then potentially the kitchen in the future when we get a new kitchen! I am in the process of looking for quotes for this. I want to get the best soundproofing possible on our party walls to block out noise this way. Does anyone know what the best soundproofing method would be to block out the noise coming from them stomping up the stairs and upstairs rooms, as this is the main contributor. Would it be a case of soundproofing under our upstairs floor boards between joists? Want to get professionals in to sort this properly so am happy to pay for the best solution possible. Just wanted to know if anyone has been in a similar situation before and had soundproofing installed and if had much joy? Any information would be appreciated! Thanks, Jack

- 7 replies

-

- soundproofing

- insulation

- (and 7 more)

-

As much as I used to like watching soaps like Eastenders, my neighbours seem to watch it all day everyday at such a high volume that I can hear it clearly in my own house. We are therefore putting up sound insulation. We were going to build a wall and attach it with genie clips (which are a type of resilient bar sold by soundstop.co.uk) to the existing party wall. The make up of the wall was going to be a combination of SBx (which is a dense honeycomb type board where the honeycomb is filled with sand) and soundproof plasterboard. My builder has pointed out that however good the genie clips might be, it would be even better to have no connection to the party wall whatsoever and have a freestanding stud wall made of metal C studs running between the floor and the ceiling, with a 10mm air gap between the existing party wall and the new wall, keeping that gap empty as opposed to filling it with mineral wool. Is he right? If so, is 10mm enough, or would i get an improvement by making the gap 15mm or 20mm? We are using resilient bars and soundproof plasterboard for our ceiling so not too worried about the ceiling acting as a bridge. As for the floor, we have dropped the FFL by about 38cm and laid an insulated slab underneath, so there is a lot of material for sound to travel through before it could bridge into our house via our floor.

-

Converting a 3 bed very dilapidated 1930s semi into a 4.5 bed modern home. EVERYTHING is being gutted except the joists. Quotes are way over budget, particularly for the underfloor heating. I had specified wet underfloor heating throughout all three floors of the house (ground = 800 sqft, first = 750 sq ft and loft = 450 sqft), with the ground being imbedded into screed and the first and second floors being laid within some high performance extruded polystyrene boards made by Cellecta called XFLO. XFLO is quite expensive, about £26 a square metre, but the reason I had specified them is that they provide good insulation to make sure the heat goes up, are CNC drilled by Cellecta to meet any pipe layout requirements we specify and also feel quite firm underfoot. The other advantage of the XFLO is that you can lay the finished floor directly onto it. Underneath those XFLO boards, I had specified a 6mm dense rubber matting (which comes as a 10m by 1m rolled product, so pretty easy and quick to lay) to absorb impact sound, and underneath that 18mm tongue and groove ply which is nailed directly onto the joists (whereas the rubber and XFLO are just floating). In between the joists I was going to have mineral wool to mute airborne sound travel, and underneath the joists I was going to have the ceiling attached using resilient bars (with market name "Genie clips") to isolate the ceiling from the joists to further prevent sound transmission. The whole system is to be zoned as 9 zones, including one zone for the 3 towel radiators (which will be the only radiators in the house, one for each bathroom), although I'm going to provide Tado thermostats, one for each of the 8 UFH zones and a Tado smart valve for each of the towel radiators. One builder has quoted about £25k plus VAT for all of the above, and the other about £28k plus VAT. These quotes don't include the thermostats (I'm providing those). When I have challenged each of them on why this is so expensive (I was expecting about half the cost) they have said different things. The first builder has said that I could save £2,500 to £3,000 money by losing UFH in the loft and in most of the first floor, and instead having radiators there. The second builder doesn't agree that would save any money and is also trying to respect our reasons for having UFH. Instead he just thinks the system I've specified for the first and second floor is overkill and that I could make two changes which would save about £4k in labour: First, instead of 18mm ply plus 6mm rubber matting plus the XFLO boards (which are about 28mm thick) I should just lay a product sold by theunderfloorheating store calledProWarm ProFloor 22mm pre-routed chipboard. I've looked this up and I see the benefit. Like the XFLO boards, you attach it directly to the joists and it comes routed (though with standard not bespoke routing) and enables you to fix the finished floor directly. It costs roughly the same as the XLFO, but it saves the builder the trouble of having to lay the rubber matting and the ply, so the saving is in the cost of the matting (£6 per sq metre), the ply (about £14 a sq metre) and the labour to fit those two layers. Second, he says that in the bathrooms, I should just lay electric UFH rather than wet. He accepts it's dearer to run, but he says I can have smart timers on it to make sure I only have it on when needed and as there will be wet towel rails in there, I really won't use it that often. I think I'm willing to accept his second point and fir the electric UFH in the bathrooms, but I'm concerned about the disadvantages of the first point, which I see as follows: 1) I lose the impact sound protection provided by the 6mm rubber - is this such a big deal given I have an isolated ceiling and the mineral wool between the joists? If so, can anyone think of a way of combining a fairly cheap but effective sound impact layer with the 22mm pre-routed chipboard? It would only ever be my kids running around, so impact sound is not a major issue, but I want some protection. 2) Chipboard is not as durable or as strong as ply. Although both will feel similar at the outset of their lifespan, what will they feel like in 12 years time? I plan to be at the property for 12 years at least, but hopefully longer and I don't like springy floors. 3) no bespoke pipe channels like Cellecta offer with XFLO. But is this overkill? Maybe I don't need bespoke pipe layouts. Builder says that the 22mm pre-routed chipboard just has channels at 200mm pipe centres and that is a standard construction for first and second floors. Although most of the rear of the house is being extended, so it will have insulated cavity walls, and the loft will also be well insulated, the rest of the house has no cavity walls. Keen to hear your thoughts on the above. Thanks for your time!!!

- 34 replies

-

I want to lay underfloor heating but also create a firm feel underfoot that doesn’t transfer footstep impact sound below. TorBoard RdB looks like it might be the perfect answer, though it’s pricy. Does anybody have experience with this ufh board product?

-

I am building a detached basement + 2 storey home, with all internal floors & walls being timber constructed. Part E seems horrendously complicated but after many readings I think that only E2 applies and that it is only Airborne test and that my internal walls can be either as type A or B and Floor of type C This seems so simple that I am worried that I might have missed something - can anyone help put me straight?

-

Hey guys, thank you so much for letting me join the forum. What a great place to find honest, experienced opinions and information. I'm working on converting a garage into a soundproofed studio and need to work out some issues with insulation and particularly ventilation. The room is 19.38 square metres so suitable for a mini-split system, which also means fewer holes in walls where sound could leak. However, I can't find out whether this would satisfy Building regs. Ideally it won't have opening windows or trickle vents, and only has one door to the house's hallway (ie doesn't access fresh external air). I guess the alternative would be to have a constant air intake and out take with a heating/cooling system but obviously that's more holes, ducting and baffling. Any advice anyone has on this would be extremely useful. Thanks so much, Andy

- 8 replies

-

- garage

- soundproofing

-

(and 2 more)

Tagged with:

-

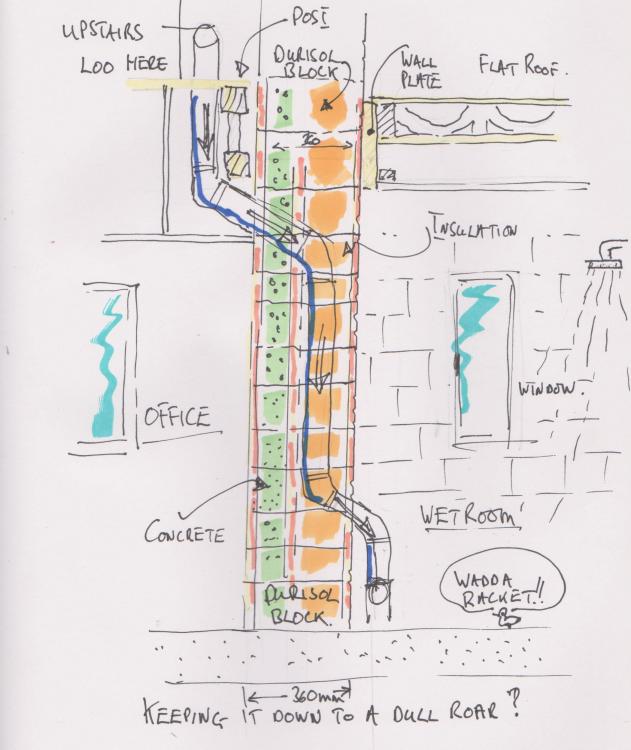

Our house design has an internal soil stack. So we need to think about noise. Have a look at this diagram. The brilliant thing about our design is that the wetroom is built onto the front wall of the house - so (below the level of the flat roof shown) there are insulated blocks inside the heated envelope. That means we can cut out the insulation and use the space created for other things - like hide a soil stack. And deaden the noise. But I only get one stab at this little problem. I need to get it right. So I'd like to fit acoustic piping (like this) or (maybe this) additionally encapsulate the acoustic pipe in sound-deadened (proofed is impossible I think) trunking. maybe double the amount of plasterboard on the ceiling under the upstairs bathroom meet and exceed the proofing levels required in Part E Have you had to deal with a similar problem? How did you work it out? Is the general approach outlined above sensible? Do you have any comments. I'm feeling a bit 'exposed' on this one.....

- 5 replies

-

- acoustic

- soundproofing

-

(and 1 more)

Tagged with: