-

Posts

3748 -

Joined

-

Last visited

-

Days Won

22

Everything posted by markc

-

The Big6 profile metal sheets “should” lay over the top, but won’t! The original sheets are unlikely to be dead straight and the fixings stick up etc. as above, remove the existing and replace. Over batten and sheet is pretty straight forward but the old sheets are likely to crack in multiple locations and you will regret not doing it right once.

-

Removing broken cast stone window cill

markc replied to Lincolnshire Ian's topic in Bricklaying, Blockwork & Mortar

To expand on the dowel - definitely worth doing but masonry style, not close fitting or you will never get it aligned as mentioned above. Drill a couple of holes in both sides fairly well aligned and use screws or pieces of wall tie as the dowels (loose in holes). Once happy it will push back into place, glue on the faces and in the holes and push it in place. If you must remove the Cill, a carbide reciprocating saw works well -

As trees mature the root growth slows and everything settles down. Looking at the pics it appears there is a ridge down the middle so some traffic compaction / settlement too. You could remove the pavers, carefefully level back up (probably need some more infil) and relay the pavers or replace with new. The pavers being easily draining are better than tarmac or concrete for the trees

- 1 reply

-

- 1

-

-

In that case you don’t need anything else, I had a similar thing a few years ago and you had to “programme” the light by flicking switch on and off a certain number of times to set how you wanted the light to behave … on dusk till dawn, trigger only etc.

-

Post a pic of your new light connections, may just need live and switched live linking, but then that could be on all the time. Post a pic of your new light connections

-

@JohnMo we had an engineer from the rigs in our place last week and he said pretty much the same regarding the politics and lack of refining

-

I try and stay out of the climate debate because I like to work on hard facts, but I do feel the problem is the “Net” bit. Net allow loads of negatives along as there are positives to make it Net. its like saying someone murdered 2 people but saved 2 others so all is good! moving our industries overseas to reduce our emissions may work out as Net but disastrous for the planet and our country

-

Hi, I'm new, looking for advice on kitchen cabinets

markc replied to bitchin_kitchen's topic in Introduce Yourself

If you have to ask then definitely don’t try making them yourself. Cabinets are available from any diy store or ikea etc. there are also a myriad of different fixings available. Your first step would be a call to your local B&Q or wickets etc. take a look and take some measurements with you, staff will be happy to help -

+1 @Russell griffiths as long as it’s only the connector with no fall you will be fine, fall along the run is to ensure everything keeps moving along.

-

I don't have green fingers, what to do?

markc replied to Post and beam's topic in Landscaping, Decking & Patios

Flail mower (walk behind, remote control or ride on) will cope with just about anything including saplings, thistles and clumpy ground etc. -

Probably bitten off more than I can chew...

markc replied to Allthegearnoidea's topic in Introduce Yourself

Good morning and welcome, being able to visualise something is a big advantage. Loads of information available on here by searching past threads and blogs. -

EJ do some decent ones, drainage superstore have them. p.s. Often referred to as block paving covers, tile variety are too shallow for grass/turf

-

The access you have is not really a constraint, for a large crane yes, but 6m beams or UC’s are unlikely to be more than 300 kgs which isn’t a problem to deal with. Mini cranes or even spider cherry pickers with lifting attachments will access very tight spaces. I think your real question is what would you prefer ? . Aesthetically and disruption while work is ongoing.

- 1 reply

-

- 1

-

-

German self-build inspiration - Poing near Munich

markc replied to RedRhino's topic in New House & Self Build Design

Ouch! 🤣🤣 -

Timber frame infill over cavity wall/steel lintels

markc replied to lookseehear's topic in General Construction Issues

Ties welded to top of beams or bent strap ties bolted or shot nailed onto top of beam will tie the blockwork in. -

Three phase supply - need a three phase heat pump and battery system?

markc replied to lookseehear's topic in Energy Storage

3 phase supply and only use 1 phase if that covers your needs, if you do have a 3 phase heat pump and want that to run from the battery then you will need a battery on each phase. Or you have the 3ph heat pump running from grid and use a single phase battery for your domestic needs and export any spare to offset the heat pump requirements. -

Expansion gap cover between old brick and engineered wood

markc replied to paro's topic in Wood & Laminate Flooring

That looks neat, I would fill with a coloured flexible filler / silicon etc. anything on top will be more obvious and as your levels look right, a cover strip would be more of a trip. -

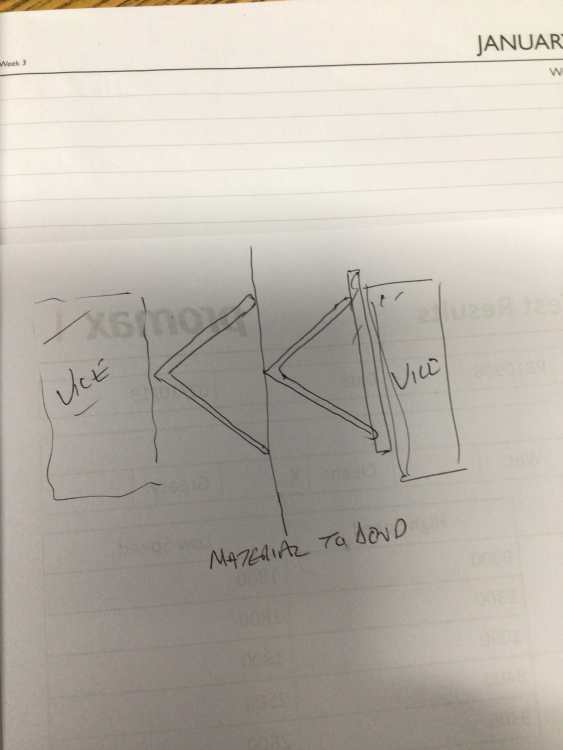

At 200mm long you can do it in a decent size vice with 2 pieces of angle to act like a press brake. Bit fiddly to hold until you get vice nipped but it does work. 40x40x3 angle would be upto this. Possibly 25x25 angle as your piece is only 60mm wide

-

Wood Bark, and just a little nominative determinism

markc replied to SteamyTea's topic in Boffin's Corner

They found that all barks consumed hydrogen, carbon monoxide and methane in aerobic conditions when oxygen is available. But when trees are submerged in water and oxygen is limited, such as in swamps, bark microbes switched to producing the same gases. This is interesting 🤔, -

I reckon you will have to go for bespoke unit, not too difficult for a job. Alternative would be two doors joined together to make a single unit.

-

If you are handy with a drill, use same size bit to rout the hole to elongate it in direction needed, bit more fiddly than larger drill but removes less material and only in direction needed. And yes we have all done it … or worse, marked several doors and fitted handles before hanging the door …..handle on hinge edge 🤫

-

I’m with Nick on this, it is surprising what you can run without any problems, and welding plants are rarely running anywhere near max so the current draw is usually pretty low (250a welding is only around 7.5Kva) and it’s not continuous unless doing big long auto runs.

-

Oak worktop and Osmo Top Oil (3068 Natural version)

markc replied to paro's topic in Kitchen Units & Worktops

Instead of sanding (which picks up the fibres) finish by scraping. I use a Stanley (other brands are available) type knife blade and drag along the surface, incline blade slightly towards direction of travel. A few strokes and you will feel the surface is very smooth. You will probably find most of the “whiting” will scrape off as you remove the “fluffy” grain patches