crispy_wafer

Members-

Posts

1144 -

Joined

-

Last visited

Everything posted by crispy_wafer

-

slight tangent, What blades/discs do you use @Nickfromwales

-

The manufacturer offers a rectified tile, so I can definitely get a nice straight edge, it's more how they look when crossing over the tumbled edge and grout line, but thinking about it that would be the same as if I selected timber anyway. They also offer a specific skirting tile, but I'd need to speak to the local tile supply man to see how much he can import them for. Quick google suggests £16'ish, if thats for 1 then that's too dear for me, and I choose the cut route.

-

yeah, nice! I do like the tiled skirting tbh. I think I'm going to wait for the tiles to be laid then I will get some samples cut and see what look we get. The tile we have chosen is a stone effect with tumbled edge, so may or may not lend itself to a tile skirting.

-

Strangely satisfying though to see a pile of materials almost disappear as they are incorporated into the build. and yeah the odds and ends that need getting rid of when finished that particular task is a task in itself. PIR offcuts I bagged them, photo'd and listed on market place. £20 - take what you want sort of listing. Inundated by people wanting it for sheds and the like, they aren't fussy, foaming and taping it together...

-

Cemfloor - Tiling - Decoupling Matt?

crispy_wafer replied to Antec123's topic in Floor Tiles & Tiling

I'm going to bounce into this thread rather start afresh, Appreciate I'm taking from the forum and not giving much back, but same situation! Cemfloor, Tiles... matting required or not. Two tilers been round, middle aged gent asks how long screed been down, I says 2 years, has the odd (3) crack coming out of doorways where expansion joints were not inserted, asks my opinion on anti crack matting me says no idea you're the expert!, he says 'good, 2 years, I don't think you need it' Younger chappie comes round at weekend would rather install matting! Now I've no idea what to do, it's budgeted for, but if I can put the £15 m2 (supply + install) cost towards doors or other fittings then I'd rather do so. But, belt and braces and all that, will I regret not doing so? -

More costly, but is tulipwood a viable material?

-

interesting, I’ve seen this on my holidays in the apartments. how have you interfaced with door architraves? We’ve having a modular rustic tile fitted on the floor, I’ll check the catalogue and see what options they have listed to see if it could pass muster!

-

To be fair, I did a cut with my old angle grinder last night to go from underneath and round the corner edge of the bathtub, took a bit of doing but turned out good I think. I’ve got an old cheap wet disc cutter but that creates more chips than McCain’s, so reluctant to use it for anything other than wall corners where the cuts will be out of sight.

-

Hmm... I will be having the floors tiled, so mopping will be happening! Nice personal touch creating your skirting. Inspired me to seek out a video, and I'm now looking at table saws on ebay - lol.

-

Looked through some old threads and conventional wisdom seemed split between MDF, and timber. We'll be painted rather than wood on show. I'm leaning towards timber, pine or tulipwood, Pine being cheaper than Tulipwood. Any wider thoughts on material choice? And longevity of MDF? Dont know if I should reconsider. If I choose timber, is it worth having them primed? Or is it not worth the hassle! - Backstory, I received some primed window boards and had to start again as the finish was like orange peel. Any decent online suppliers that you've used, I've bookmarked a few that I have come across.

-

Thanks @Nickfromwales @Nestor, ordered myself a Sigma, and treated myself to a cordless angle grinder, a diamond cutting disc, and some edge polishing pads! These should see me right whilst I sort out the bathrooms.

-

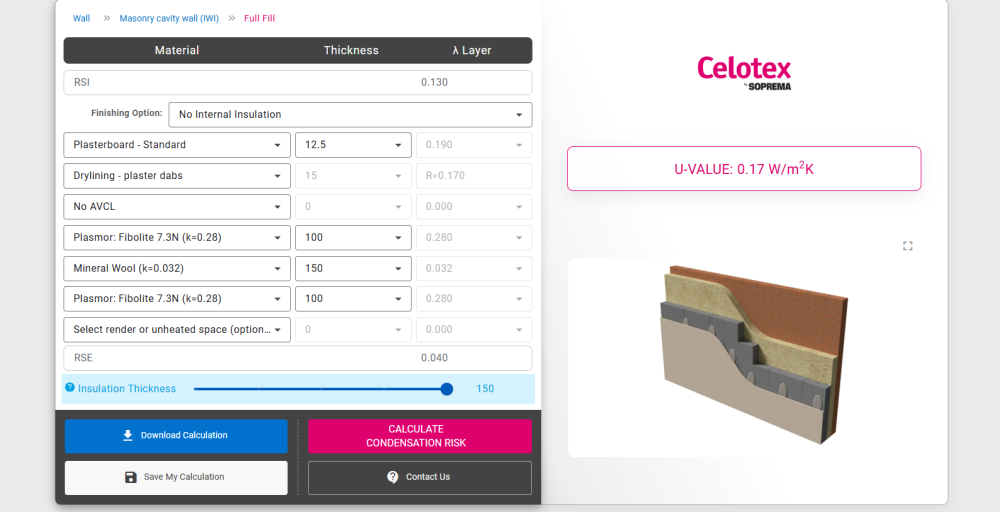

out of idle curiosity more than anything, why 7.3 on the outer leaf? anyhow here's the u calculator from celotex, I haven't double checked it. U-value Calculator | Online

-

I'm in need of a tile cutter and looking for recommendations please. It's going to used for various porcelain wall tiles, probably with a depth no greater than 12mm. Mostly 600mm*300mm. We're not planning any tiles with diagonal face cuts. This is going to be a tool I'm going to use over the next few months then sell, so something that would be sought after secondhand would be good. Rubi, Sigma? So many models it's confusing?

-

Shower tray fitting on wood decking

crispy_wafer replied to G and J's topic in Bathrooms, Ensuites & Wetrooms

I think you’re pretty well covered with advice, but I’d second getting as much tanking done beforehand, for what it’s worth I also covered the floor, any joints that were under the tray too, and all round the keyhole for the waste. Flexible tile adhesive was also used. oh, have an old towel, some wipes nearby, and someone nearby to help wipe down cos tile adhesive sticks like sh*t and gets everywhere you don’t want it too 😂. -

For what its worth, pert al pert will form and hold it's own bend, and is pretty robust. I did what JohnMo has suggested above, sleeved in flexible conduit, cheap stuff from toolstation or screwfix I think.

-

We used plasmor fibolite blocks , don’t seem to be bad blocks to be fair!

-

or these perhaps. FloPlast Fixings Black 50mm x 2mm 10 Pack - Screwfix

-

just a thought, I wonder if some black screw caps would look ok.

-

Time for some new Makita goodies- any good deals on?

crispy_wafer replied to Crofter's topic in Tools & Equipment

I use hotukdeals quite a bit and have alerts set up for the yellow and black tools. Good to get alerted when the offers are on. -

Can I ask how you lifted the stairs. I’ve got a steel mono spine and, on my own trying to work out methods to lift and manoeuvre.

-

That’s interesting, and very nice, you must be pleased and proud of that? It’s nice you’ve incorporated something you chopped down too.

-

Plasterboard Fixing Failure at Window Reveal

crispy_wafer replied to Spinny's topic in Plastering & Rendering

Right, I’ve a thought, but you might not like it…. Can the inner habito section be dismantled? If so, get that out the way so you can get a good access to the block work, then mechanically fix a length of timber to it. Or perhaps a 15mm*25mm angle but flipped inwards so you have the 15mm facing inwards, bond or mechanically fix to the frame. The reveal board when plastered will cover the metal. me, I’d look to my first option. I think @Iceverge may have had solutions for tricky reveals in the past? And @Nickfromwales may have seen a situation like this out in the wild. Sorry for tagging you chaps, this one needs more than my willing head! -

Plasterboard Fixing Failure at Window Reveal

crispy_wafer replied to Spinny's topic in Plastering & Rendering

Ooh, now…. Wait for the experts to appear, but my initial thoughts would be bonding 25mm angle to the frame top to bottom and using this to fit the reveal board to. -

Removing broken cast stone window cill

crispy_wafer replied to Lincolnshire Ian's topic in Bricklaying, Blockwork & Mortar

Wonder if one of those magicman outfits could effect a repair on something like this. a quick google and this bod has done something with a cast stone corner block https://magicman.co.uk/examples/