-

Posts

686 -

Joined

-

Last visited

-

Days Won

1

oranjeboom last won the day on July 22 2016

oranjeboom had the most liked content!

Personal Information

-

Location

Kent

Recent Profile Visitors

5242 profile views

oranjeboom's Achievements

Regular Member (4/5)

118

Reputation

-

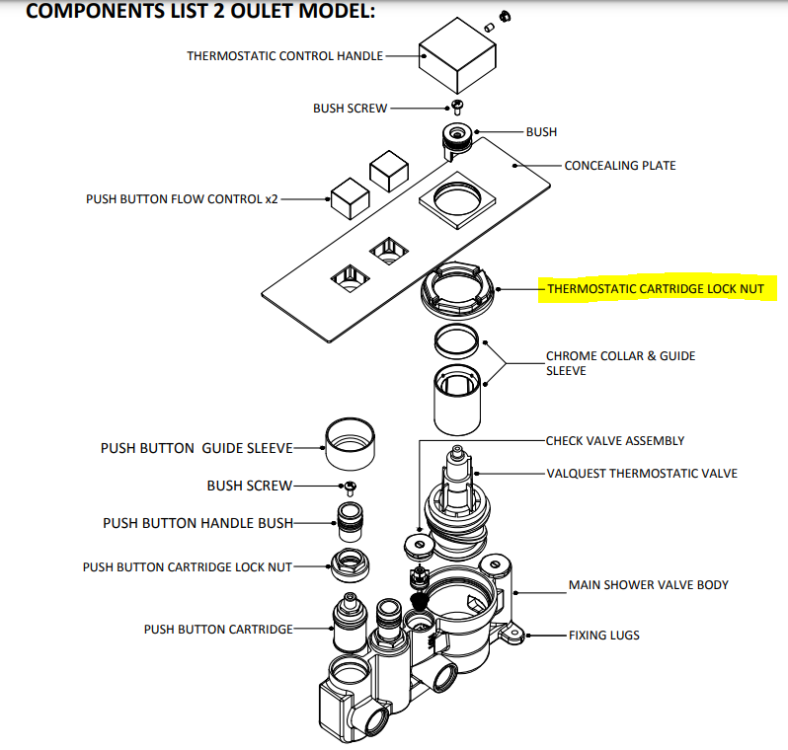

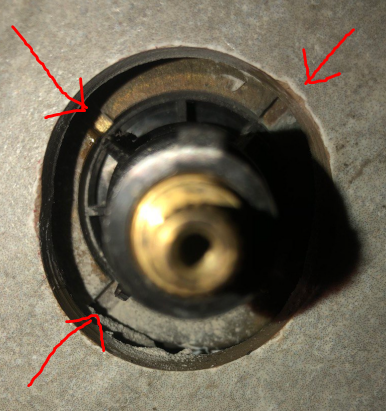

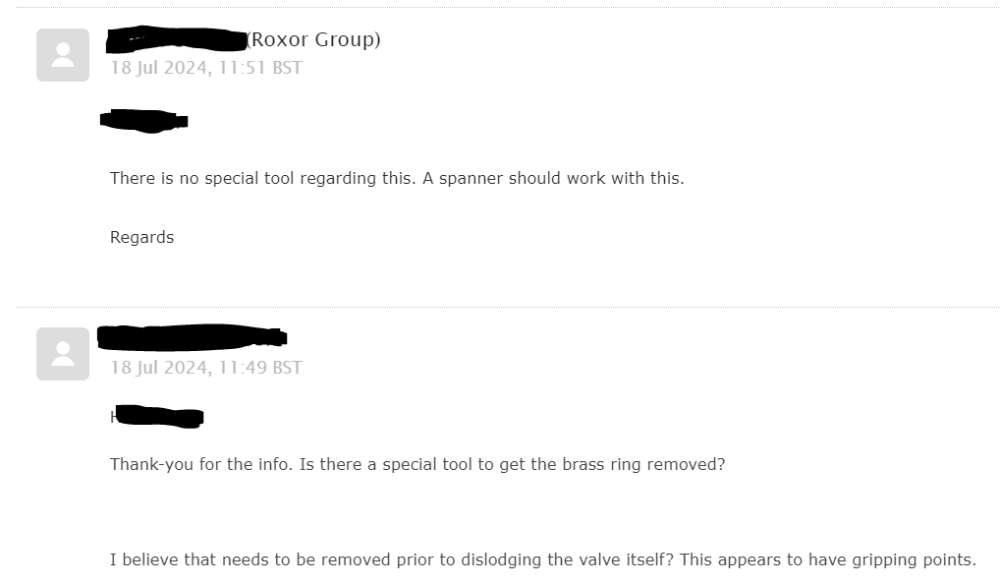

So after 5 years use, the water's luke warm in the shower and all other outlets are bloody hot. I've got a water softener too, so it's annoying that the valve has still buggered up. It's a Hudson Reed unit and I know that the valve is this one: https://www.divapor.com/spares/showers/thermostatic-cartridge/sc50t20-crosswater-thermostatic-cartridge-valquest-sc50-t20-and-sc50t20-m.php?gad_source=1&gclid=Cj0KCQjw-uK0BhC0ARIsANQtgGMIRbE611NVsfsByzD4XmXFkvYy08D1bFRQCgdIYfe25_D5WMzCvjwaArD1EALw_wcB The issue is that the tiling is very tight and I'm hoping that there's enough space to get something in there to dislodge the ring (see below). Due to the depth of the ring behind the tiles (2-3cm) I can't get the angle right for a screwdriver and light hammer tap. Is there a special tool for this job? I've contacted the manufacturer and they're telling me a spanner should do the job....how you're supposed to get a spanner in there I don;t know! Thanks in advance!

-

Trench for ASHP pipework, electricals - tips?

oranjeboom replied to oranjeboom's topic in Air Source Heat Pumps (ASHP)

Thanks ! I think I may recall reading about your DIY approach on here some time ago, but do you have a link to that post by chance? I'm hopeful that installer is supplying my insulated pipe as I've seen the crazy costings! -

So after much faffing around with suppliers, Ofgem and installer, it looks as though I now have a date for my heat pump install (Vaillant Arotherm Plus). Now looking to prepare for the install so looking to dig a trench to determined ASHP location and shortest route to house. Due to the nature of driveway (just to left of hedge, see below) and the line of sight from the gate, the best place visually is indicated by spade). As it'll create a bit of an eyesore and also being adjacent to front door, locating it right next to house is not possible, so I will locate it 9m from the nearest entry point (see rough tape measure line below). Pipework will then go up the wall 2.4m.. through soffit, into loft...1m along the insulated loft...then down through ceiling and into plan room (another 3m), so approx 15.5m in total. The exterior wall is still to be covered by EWI at some point in future so that will cover all wiring and pipework. So, I have a few questions: How deep should trench be dug? 500mm? Armoured cable necessary or can I just use standard cable in conduit I just bury it below the pipework with warning tape over the top? Obviously heat loss is an issue so wanting to minimise that if I can, so I was going to lay the insulated pipework ontop of some EPS leftovers and add some expanding foam prior to filling in - worth it? Any other ideas? Thanks in advance

-

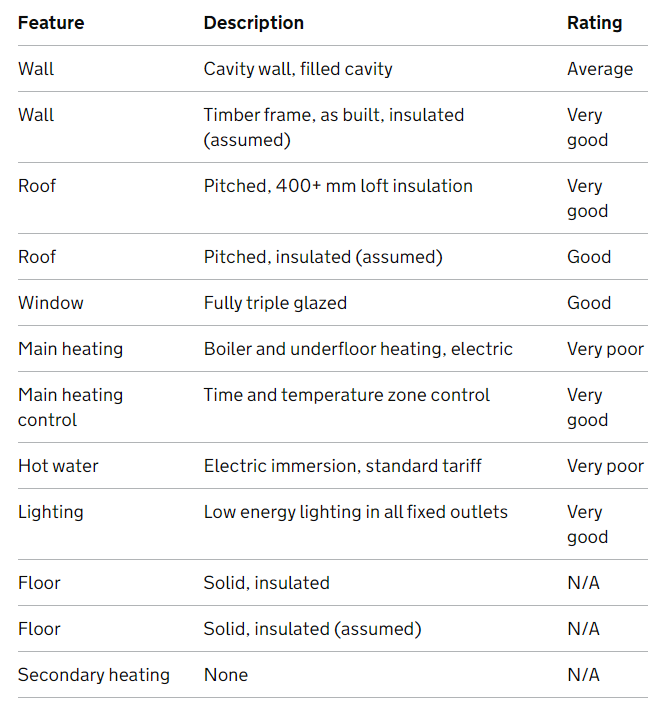

The extensions are SIPs 175mm walls, 200mm roof iirc. Again, no SIPs option so he went for timber. The older part of the bungalow is cavity filled. MVHR...no idea what default values he went for. Yes, he was friendly enough and took his time to look at all the options. But yeah, no idea why the 3G is just 'good'. Proper German windows too! May contact him to see why!! "Computer says...."

-

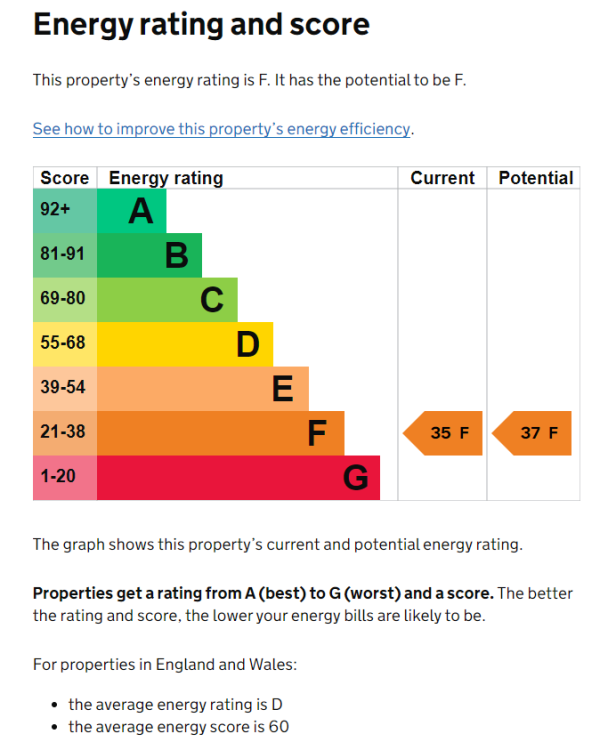

So had my EPC survey done this week as part of the BUS grant application for the install of an ASHP. My last EPC was a "D" before renovations and extensions with oil boiler and rads. But not this time!! Now after spending ££££s on 3G windows and doors, 400mm of slab insulation, UFH, 400mm loft insulation, MVHR, 2x Sunamp units, low energy lighting, cavity insulation, solar PV, I get an "F" for "failure"! "I've done well over two thousand surveys to date and this result has been the hardest to comprehend." was the assessor's comment. All a bit ludicrous how some of the 'better' newbuilds up the road achieve a "B" when they probably perform much worse on heat loss I suspect. I believe the result all came down to the fact that I have 2 Willis heaters doing the UFH...deemed as inefficient as it was only enterable as an electric boiler. As for the Sunamps, again the software could not compute those. And it also does not cater for 3G doors! I bet if I was totally self-sufficient with PV it would still label the endeavor as a failure due to the fact that it's all electric!! Not looking to sell the house in the near future and assume I could get a new one done after the ASHP is installed...not that the rating bothers me. Well...I'll wait for when the EPC $hit gets replaced with the next improved $hit... Looking on the forum, be interesting to know how you achieved your rating @Russdl !!

-

Yes, that's who I've been buying from in the past and they still seem to be the best for pricing now. I've got a discount code that gets the price down to 62p/kg. £120 for 24 blocks inc delivery. Some of the ebay pricing is ludicrous!

-

Just bumping this up.... Looking to replenish my salt block stop... Just about to run out. Best price I have is £2.60 (per block including delivery). Anyone seen cheaper than that? I've checked a few places, but that appears not a bad price. Anyone in East Kent looking to buy a sizeable amount and willing to share a pallet of the stuff?

-

Hi Terry, Looks as though I am too late - I would have been interested in the working unit as mine are of the same ilk and I probably would have driven up to collect. Alas...

-

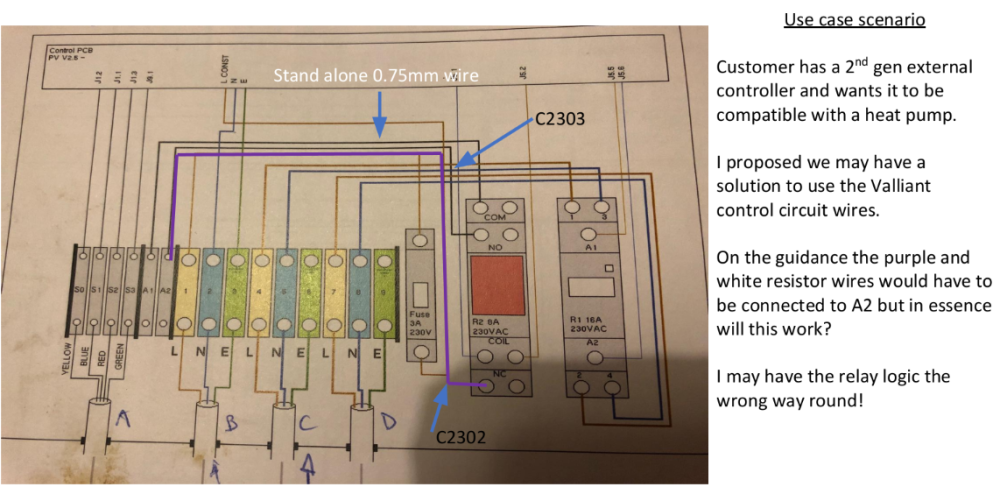

So this is what the installer has come up with in tandem with Vaillant (see PDF). Still awaiting for Sunamp to review and approve that. Sunamp also came back with this suggested fix for the external Sunamp control unit (which I have questioned whether this is their 'final' solution as the wording seems a bit haphazard!): Vailant and sunamp schematic (1).pdf

-

I've just tiled the fireplace inset with 'special' tile adhesive that cost a leg and an arm. And a sore back. Whilst some folk on the interweb state to use special heat-proof grouting also, there are others (e.g. https://stovefitterswarehouse.co.uk/pages/tiling ) that state there is no need and to just use the standard grouting. It'll be approx 3mm grouting. 10kW log burner. Any real experience on here with people using std grout or should I just go and use Vitcas grout or similar? TIA!

-

Yes, I have an earlier model, the "eDual", external controller which is the issue as it does not rely on a heat sensor. 65 degrees I believe