-

Posts

4393 -

Joined

-

Last visited

-

Days Won

31

Everything posted by Iceverge

-

Where's North please? Am I correct in assuming this is a complete new build from the ground up or are you reusing foundations? Do you have any neighbors that you will be in danger of overlooking?

-

Week 40 - We’ve moved in!

Iceverge commented on Benpointer's blog entry in Contemporary build in north Dorset

Congratulations. I like the forest shower. What is that?- 14 comments

-

- moving in

- airtightness

-

(and 3 more)

Tagged with:

-

I would do 10mm to every hot tap except the shower and bath. 6l/min is what we get at the kitchen tap and I think it's plenty. If you want 10l/min I just blend in a bit of cold with the tap mixer. It also limits less economical types than yours truly pouring endless quantities of hot water down the drain too if you're feeling a bit scrooge like.

-

Chemical anchor and threaded rod.

-

Congratulations on moving in. You could borrow a thermal camera and check what the worst offenders are.

-

https://airtightnesstapes.co.uk/products/3100-black-airtight-tape?variant=48379082309911 This stuff looks identical to the stuff I used but a different brand. It doesn't look fancy but i was very impressed with it in person. Better than the Belgatape and Tyvek tape. I've used it externally on the garage too and it survived the weather for 6 months before I clad it.

-

Some small lumps of insulation I found around I just tossed them into the sea of blown cellulose in the attic. They sit there little boats, reducing my energy loss by nanoWatts.

-

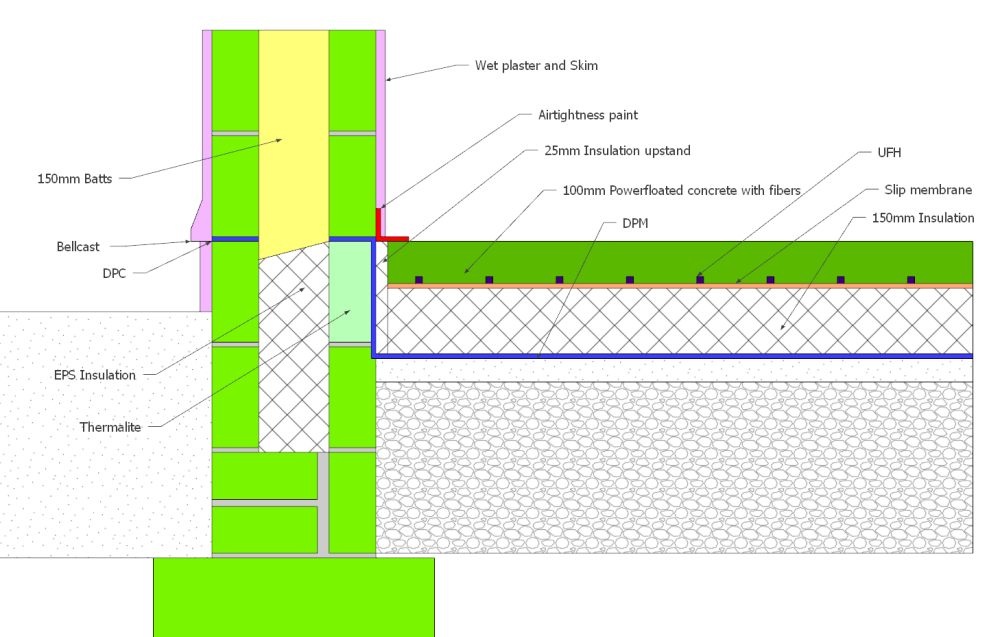

Ran this through a few times in THERM when doing ours. It is worth doing a layer of aircrete in line with your floor insulation. You also need to have continuous insulation outside it. They must be kept dry as they loose most of their insulative qualities otherwise . I would make sure the cavity extends at least 1 block below the Aircrete to make sure there is no water ponding there. This detail would perform very well and is fairly cheap. We filled the whole cavity with EPS beads (ok for use below DPC) so it was a simpler detail to construct.

-

I know a house with that. It looked sharp when new ( although it really exacerbates anything less than a perfectly level floor). However it with the passage of time, kids and vacuuming etc the bottom of the wall has become a bit scruffy.

-

MDF here. It's been fine apart from any edges that have gotten wet. It is just mush really when it comes to taking screws or impact. I don't think it'll last the journey. The dust is horrible when cutting too. I'd much prefer to work with pine. Is there any cement board options? Maybe hardiplank etc? I think you can uPVC too but I've never seen it.

-

Has anyone got examples of Dot and Dab blowerdoor tests(not gamed!)? Did anyone get below 2ACH ? When it comes to passivhaus airtightness the build types I've seen to have achieved those levels are wet plaster, tapes membranes/boards in timberframe, ICF, SIPS. Two one offs were @Gone Wests Icynene TF and an archive building somewhere in England that used Passive purple paint. I haven't come across any dot and dab getting below 0.6ACH.

-

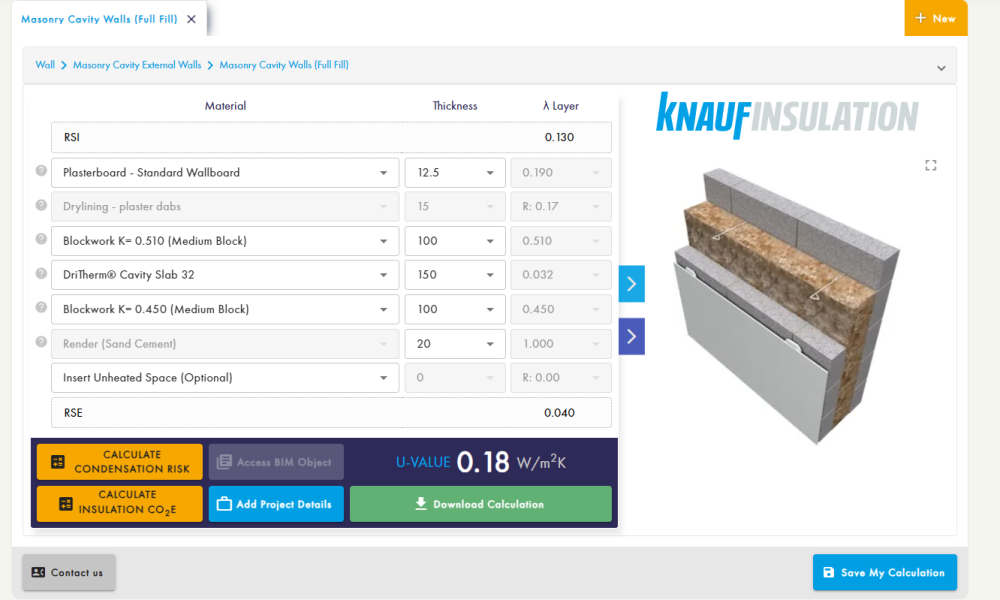

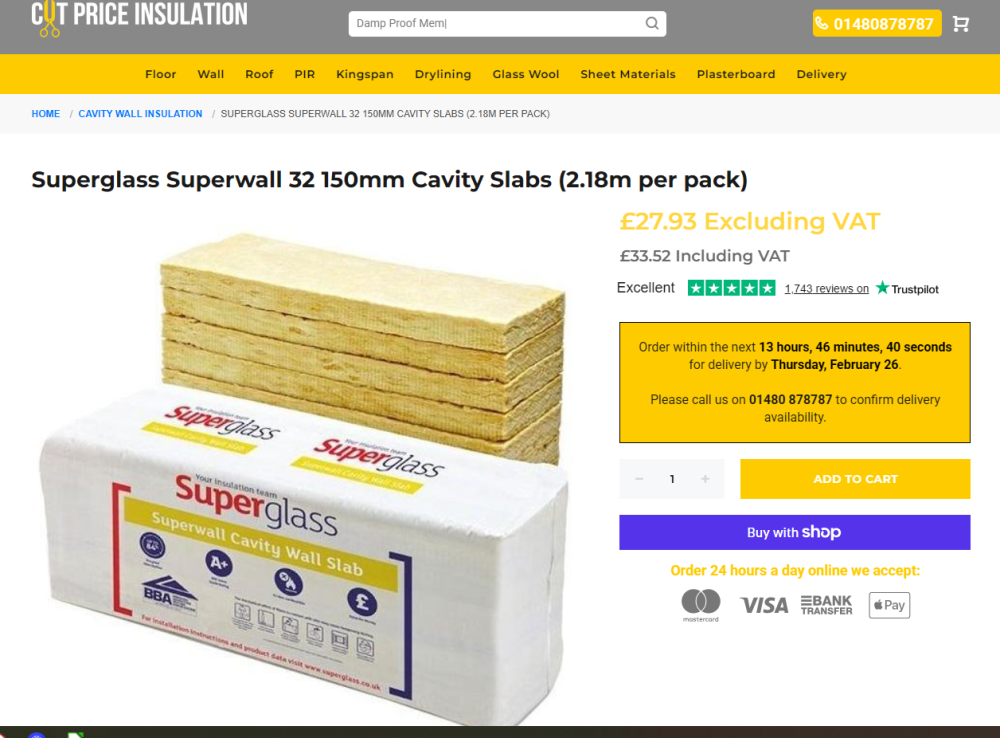

Change that to medium blocks inside and outside and you get to 0.18. That's a nice calculator actually by Knauf. It is fairly optimistic with the values it's allowing for the airspace behind the plasterboard though but it'll get you through regs which I'm getting the impression is the aim. Hemelite blocks are a small bit cheaper too. Superglass is a bit cheaper again than Knauf. £51.37 inc VAT per m2 for the blocks and insulation.

-

I looked at earth tunnels when we built but came to the same conclusion as @Gone West. Minimal energy gain with the drawbacks of mould growth in the pipe and high install costs. As usual sitting down with a calculator and a biro very quickly dispells incompletely though out ideas. Passive stack was another. There's only 3 practical options really. 1.Trickle vents and extractor fans if you don't care about indoor air quality, noise, thermal comfort or energy use. 2. Humidity sensitive mechanical extract. Upgrade to humidity sensitive vents if possible. Good IAQ. Some energy loss. Minimal maintenance costs but some cold spots in the house. 3. MVHR. Excellent IAQ, minimal energy loss, best thermal comfort, no cold spots or noise. Higher maintenance costs may not be offset by lower ventilation losses.

-

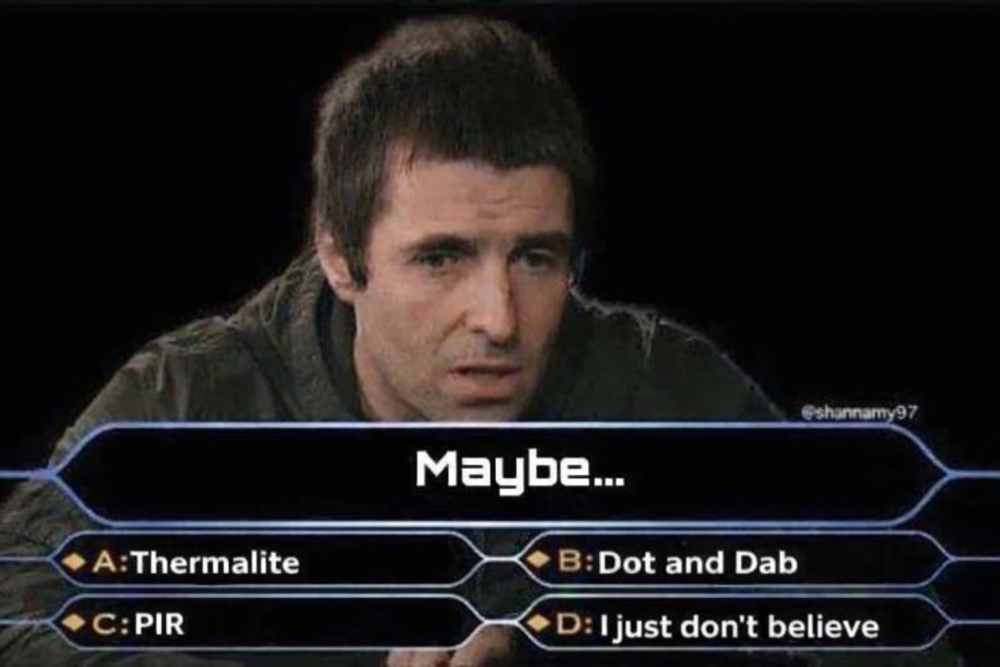

But is very poor for airtightness. PIR boards are routinely installed terribly with lots of thermal bypass. There's plenty of threads on here to look at. For the same U value ........ a Wet plaster + double dense block + mineral wool batts will far outperform a Thermalite, PIR, Dot and Dab Wonderwall (don't sue me Oasis) As to the "lost" floor area just push the walls out by the same mm.

-

Rebuilding after demolishing question

Iceverge replied to dustyb's topic in General Self Build & DIY Discussion

-

Oversheeting 'Big 6' fibre cement roof

Iceverge replied to Glenn's topic in Roofing, Tiling & Slating

Regarding insulating insulated sheets aren't tremendously expensive. Even a minimal 25mm or so of Insulation would be worth it. If you really can't afford it or just want to stop condensation drips I would layer a run of chicken mesh over the purlines to support roofing felt and then use standard sheeting. There's a roof very almost level done on a stable here and it has never dipped. -

Oversheeting 'Big 6' fibre cement roof

Iceverge replied to Glenn's topic in Roofing, Tiling & Slating

Yikes...... Sounds like a recipe for a forever roof.Not in a good way unfortunately. What you have at the moment can be tackled systematically and safely. If you layer up new roof on old asbestos noone will want to come within a mile of it . If you take appropriate precautions you can remove the Asbestos yourself and get it disposed correctly. If you're able to take the time and care it'll save a lot vs a contractor. -

That drawing seems to carry some magical thinking in a few areas . I'm really not certain what went on in this area. It doesn't fill me with confidence that your designers details were up to scratch. Do you have any specification as to what the builders were working to? Any pictures during construction? What is your specific objection to the work? Aesthetics or is it unsafe or leaking? What may help is if you have any wider drawings of the same area. Particularly sections.

-

There's a mistake here. I think I should have said 200mm cavity in the second example.

-

Upgrading rafter ties to proper joists

Iceverge replied to SimonD's topic in Garage & Cellar Conversions

How "good" does this need to be? I'd be surprised if you couldn't wiggle something up into place. 50mm would be enough bearing. Maybe use 2 plys of longer bendier timber like 150*25 instead of a single 150*50. You could "truss" the roof by adding vertical support to the existing joists from the rafters. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Iceverge replied to fatgus's topic in Heat Insulation

Economic fabric first probably wouldn't be very nice to live in. It would only include the smallest windows necessary for fire escape purposes and they would be the lowest legally acceptable spec. For comfort I would always upgrade to thermally good windows before going behind Bregs insuation. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Iceverge replied to fatgus's topic in Heat Insulation

Good quality 3g white/white uPvc. Anything more expensive is just buying an Audi instead of a Skoda in my view. More $$$ without any more performance but at least the neighbours will be envious. -

Standard dense blocks 7.5N is the norm in Ireland. Thermalites really add almost no insulation compared to making the cavity just a few mm wider. They're lighter to lift but crack easier and don't take wet plaster as well. Swings and roundabouts. 100mm dense blocks 175mm cavity batt 36 100mm Thermalite (0.18) will get you to 0.18W/m²K. Blocks and insulation~£65.14/m² If you used 100mm dense block 175mm cavity batt 36 100mm dense block ~£48.12 per m² You'd be at 0.174W/m²K

-

Yes sorry I was speaking in a general sence. Talk to the SE on this case. From further research and it might have some favourable qualities for a raft foundation. Flows well around complex reinforcement. Less heavy work with rakes and boots ducting the pour would mean less chance of damaging the UFH pipes.