Search the Community

Showing results for tags 'sole plate'.

-

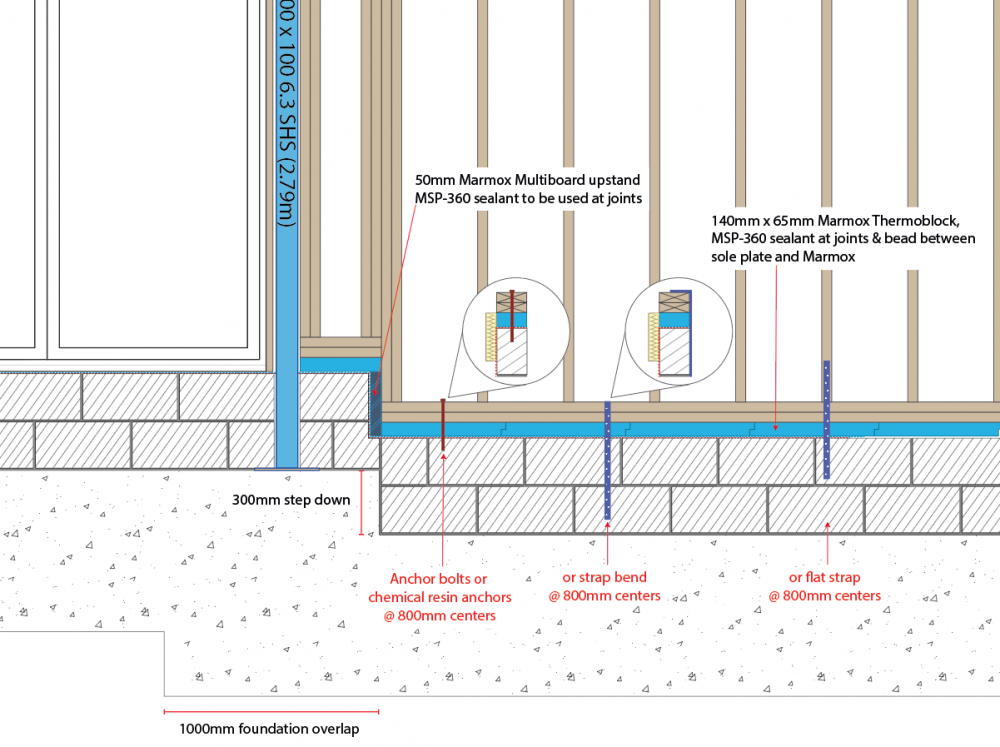

Hello all I'm at the stage where I'm looking for the best solution to strap/bolt down the soleplate of my TF to the blockwork and I am looking for your opinions/advice. I'm currently looking for one of the following options fixed @ 800mm centres: - Anchor bolts down through the soleplate. - Chemical resin anchors down through the soleplate. - Strap bend on the outside of the blockwork going up and over the soleplate. - Flat strap on the outside of the blockwork that goes up the studs. Any advice and help would be greatly appreciated.

- 28 replies

-

- sole plate

- marmox

-

(and 4 more)

Tagged with:

-

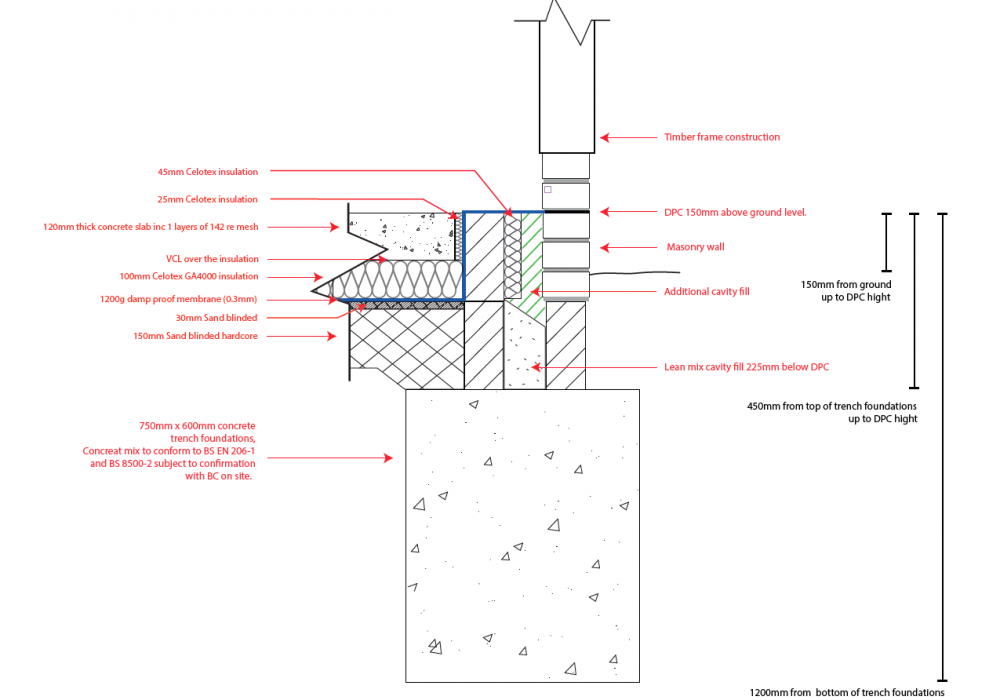

Hello all, I'm after some help understanding if the following drawing is correct for a timber frame building to sit on. The building is a two-story extension and is to be clad with timber feathered edge, not a brick cavity wall. Any help would be greatly appreciated, Cheers.

- 21 replies

-

- timber frame

- foundations

-

(and 4 more)

Tagged with:

-

Our frame arrives on Thursday & I've one final course of blockwork to do which I'll give extra attention to in terms of levelling in preparation for the sole plates. Do people generally bed sole plates on mortar or dry lay them? I'm not expecting to need any packing if I'm careful with the final blockwork as the levels are currently within 2/4mm over 10+ meters.

-

Apologies in advance for dragging up an old topic.... A large element of our build requires the use of a beam and block floor on strip footings. In an ideal world this wouldn't be the case but our site dictates it. As mentioned in other posts we are using an i-Stud frame and whilst not expecting passive standards, would like to do the best we can. I've read numerous threads regarding the issue of sole plate decay through condensation when using a cold foundation detail such as ours, and if possible I would like to minimize the risk. I'm happy to consider the use of thermo blocks etc if they are genuinely required but wondered if a simpler solution exists. I've read several comments suggesting running external insulation above and below the sole plate however that isn't possible without significantly increasing our vented cavity. The detail below uses a 215mm block with the 245mm frame overhanging by 30mm (approved by the frame engineer). This would allow space for 40mm of EPS directly below the sole plate and continuing down as far as necessary. I would finish this in a similar way to some of the MBC houses on EPS slabs - fascia board etc. Does anyone think this would be enough to minimize the condensation risk? Another option seen on the touchwood site is a basic cavity wall concept filled with EPS on which the sole plate sits, would this be a better option? Both are viable for us in terms of footing width. As always comments greatly appreciated. DewPointDetail.pdf

-

Hi guys, I am converting a sun-room into a kitchen, I am currently waiting on planning and warrant. To put you in the picture the existing sunroom is constructed of a cavity wall to about 600mm AFFL but externally about 1500mm above ground level, so the wall is actually about a 2000mm wall from the foundations, it has a 100mm cavity and is built in 100mm concrete block - see photo attached, I removed some PB to do an inspection. The top of this wall is then closed, and UPVC windows are fitted around 3 walls. The proposal is to convert it into a proper room which the kitchen shall move out to. So the questions begin! I had a look through the building warrant drawing and this is what it says: Cavity wall construction consisting of 19mm render on 100mm block with 50mm clear cavity and 145mm internal timber frame construction consisting of Tyvek Reflex insulating breather membrane to BS 4016 on 10mm plywood sheathing on 47 x 145mm SC4 pressure impregnated timber studs at 600mm centres. Walls finished internally with 12.5mm Foiled Back plasterboard on 70mm insulation on perimeter walls internal areas as standard plasterboard and 12.5mm moisture resistant plasterboard to en-suites, bathrooms and utility room, all joints taped and filled. 140mm thick Celotex XR4000 or equal fixed between timber studs with Visqueen vapor barrier stapled to internal face of studs in Bathrooms. Within 125mm studs allowance of 25mm given to run services within timber framing. This is clearly my architects standard paragraph, but to adhere to it as closely as possible my thinking is that I shall need to sit a 145mm sole plate on the top of the inner concrete block, but what about the 45mm difference, the construction method above says a 50mm clear cavity, so my thought is that if acceptable I can allow the timber to overhang 45mm into the cavity, but with 10mm ply (local merchant does 9mm or 12mm ply and OSB... so I was going to use 9) but that then means the clear cavity is only 46mm - I suspect I may get away with this or do I need to overlap the frame 5/6mm into the inside of the room. Anyway, I am sort of thinking aloud there, what is acceptable - 145mm frame on a 100mm block wall? The next thing I note is it says, "Walls finished internally with 12.5mm Foiled Back plasterboard on 70mm insulation on perimeter walls" so does that mean that between the studs in my extension I need to put 70mm (seems a bit thin by today's standards) insulation, then attach foil-backed PB to the studs - job done wall built. But I then read the sentence about the 140mm Celotex as saying I need to put 140mm insulation between the studs and a Visqueen VB if a bathroom, OR does the whole sentence apply only to bathrooms? Badly written sentence frankly, 2 interpretations for sure. If it does only apply to bathrooms it should say, " Within bathrooms 140mm thick Celotex XR4000...". What are your thoughts here? Thanks