Search the Community

Showing results for tags 'cold bridge'.

-

My foundation plan looks like this: The two piers that are right in the middle (I’ve drawn a purple ellipse over one of them) are there so the entrance hall (in the middle at the bottom of the picture) will be open plan onto the kitchen, which is in the middle at the top of the picture. I envisaged 100mm wide concrete block piers being built up off the top of the poured concrete foundation (where the piers are) all the way up to the RSJ that will support the side of the landing that overlooks the galleried entrance hall. The top of the stairs may also be supported on this RSJ.

-

I am working with a structural engineer specialising in Traditional Timber frames to design a new build Wealden Hall House. Could anyone point me towards a person / company with a good degree of experience in efficient building design for traditional timber frames? Pursuing a truly historically-accurate frame design results in some specific cold-bridging issues (use of continuous timber posts / plates / joists through cross sections), that we are seeking mitigation strategies for. Thank you.

- 3 replies

-

- timberframe

- passivhaus

- (and 9 more)

-

Hi, I have an extension built on my home which my Dad, who has since passed away, built in 2011. The extension has always been very very cold compared to the rest of the house. The rest of the house is built on solid floor. We had tight site access so my Dad decided to do a suspended floor rather than a solid thinking it would be easier to get materials on site. I always suspected the floor was the problem as the air gap underneath is about 600mm deep due to the ground level that connects it to the rest of the house. But also upon opening the floor I found it was built on posi-joists. The architects drawings I found stated that it needed to have 100mm of PIR board between each joist, which they did install - but at the top of the joists. As the joists are about 200mm deep this mean it left the bottom 100mm open and allowed the cold air to directly reach the top chord, which is 47mm thick. Effectively this would be like having your outside wall made of 47mm thick wood and then just having plasterboard directly on top. No wonder it was cold! So now I need to figure out a 'safe' way to insulate the joists. What I wanted to do is push the PIR board to the bottom so it was level with the bottom chord - possibly use gapotape too (though that might be unnecessary in this idea) effectively creating an air tight seal at the bottom. Then I was going to put sheep's wool insulation inbetween the metal fixings of each joist - making them full. Finally a sheet of SuperQuilt on top to act as a vapour barrier, an air tight seal for the room and foil to reflect the underfloor heating back - it would also have an air gap between the top of the PIR board and the bottom of the quilt and from the top of the quilt and the chip board subfloor. My biggest question is that in doing this the top chord of the posi-joist would effectively be sealed off from the fresh air void below by the PIR boards. Could that cause any issues with damp/rot? Or does it just mean the top chord is now part of the warm room? (though sealed off from the main room by the vapour barrier) If so I don't see any real way to fully insulate away the issues but also keep the top chord access to the fresh air. I think the only way I can think would be to move the PIR board up so there's a gap just above the bottom chord, but keep it full of sheep's wool so that it's got nearly 200mm of insulation before meeting the top chord - it at least will be in theory then "breathable". The top and bottom chords on the joists are 122mm wide and 47mm thick on 600mm centres. I suspect there will be a school of thought in the best way to go about this. I could find little to nothing regarding insulating posi-joists online with such a large cold air gap below. The architects specified Wolf easi-joist WS200 - I asked them this exactly insulation/breathability question and included the photo. That appeared to be a mistake as apparently whilst identical, these are not official Wolf easi-joists, so he wouldn't answer the question, even on an "in theory with this type of top/bottom chord split". Look forward to hearing thoughts.

- 3 replies

-

- posi-joists

- subfloor

-

(and 1 more)

Tagged with:

-

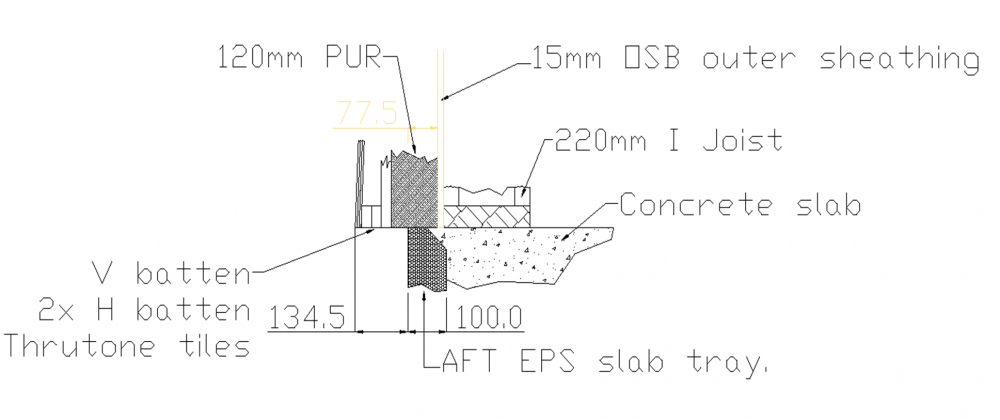

Been working hard on the plans now we have had the all clear from BC, managed to get the stair design put back otherwise we are good to go. In drawing things up I came across the build up below from the architect. Its only on a portion of the front and rear walls (the others are 300mm I joist and 40mm PUR) but I am worried about several things and though I might seek thoughts from THE forum. My concerns are: 1. How to seal the bottom of the PUR to the top of the EPS to ensure no cold bridging? 2. What methods are there, other than long nails, to fix the Vertical battens through the PUR to the I joists (which only have 36mm thick flanges) and will these support the weight of tiles, horizontal battens and fixings. (I had thought of M12 studs fixed to the flanges -bolted both sides, and then fed through the PUR at intervals but it feels like a phaff although it won't be much of a cold bridge overall it feels like a great dew point opportunity. 3. What sort of thing (detail) can I do along the bottom of the overhang to make it look good, seal the bottom from insects but allow air flow up behind the tiles? Any thoughts greatly appreciated.

-

- cold bridge

- passive slab

-

(and 2 more)

Tagged with:

-

Meanwhile, back at the ranch, we decided not to trust even one block laid by the original builders. And that means treating the Durisol like, well, the wall at Blackpool sea front. I know, it's tantamount to an admission of defeat. But do we want a wall we can trust or not? Short of scanning each block for integrity (well nigh impossible) there's nowt else we can do. Have a look at those lovely lengths of threaded bar fastening the OSB to a similar support structure the other side of the wall. My God I can cut and trim threaded bar to size at speed now. And in doing so have presented myself with 60 cold bridges. Poo. Here are two ideas that we have come up with to fettle the issue. A few hours after the pour, undo the nut on the outside (insulation side of the ICF) and tap the threaded bar back in (say) 60 mm, and fill with foam. Allow the concrete to cure. Remove the sheeting, and drill back the bar from the inside this time. Fill with foam. Leave it. Allow to cure. Drill out 120 (both sides of 60 bars) to a depth of 60 mm, fill with foam Has anyone got any bright ideas? Please? Hope so Ian

- 79 replies

-

- icf

- cold bridge

-

(and 3 more)

Tagged with:

-

This door threshold detail provided by our Architect appears to have a major cold bridge in the form of the pre-cast concrete threshold. Can anyone suggest an amendment to the detail to remove/reduce the cold bridge? Thanks John

- 18 replies

-

- cold bridge

- door threshold

-

(and 1 more)

Tagged with: