OldSpot

Members-

Posts

76 -

Joined

-

Last visited

Recent Profile Visitors

1333 profile views

OldSpot's Achievements

Member (3/5)

6

Reputation

-

Steel Ridge beam to rafter connection details

OldSpot replied to OldSpot's topic in Roofing, Tiling & Slating

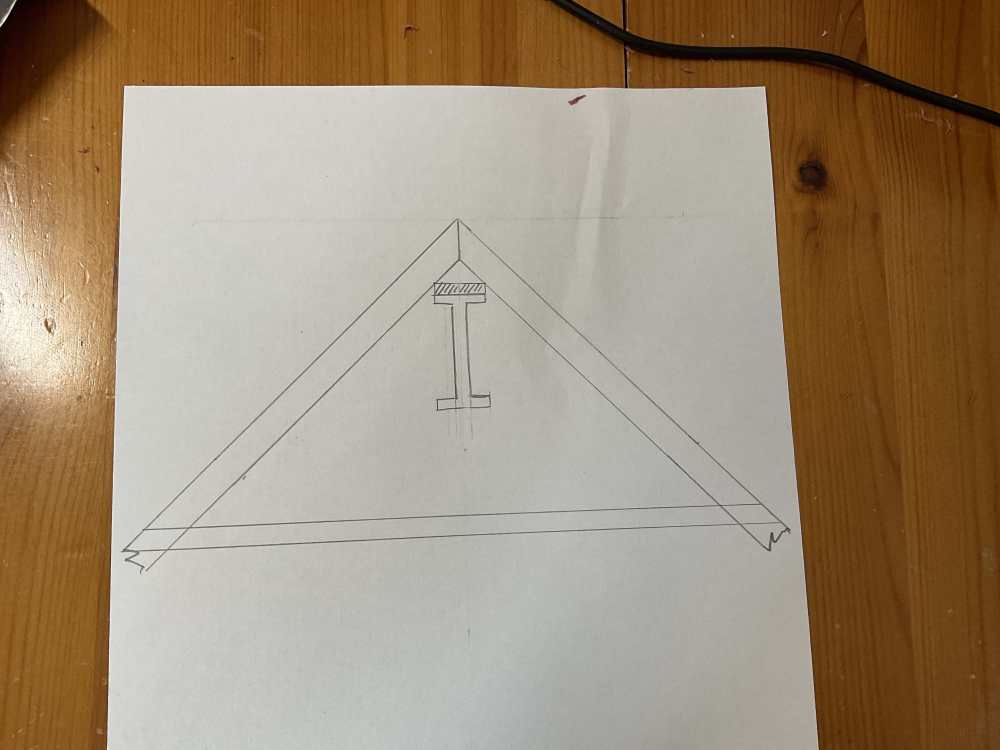

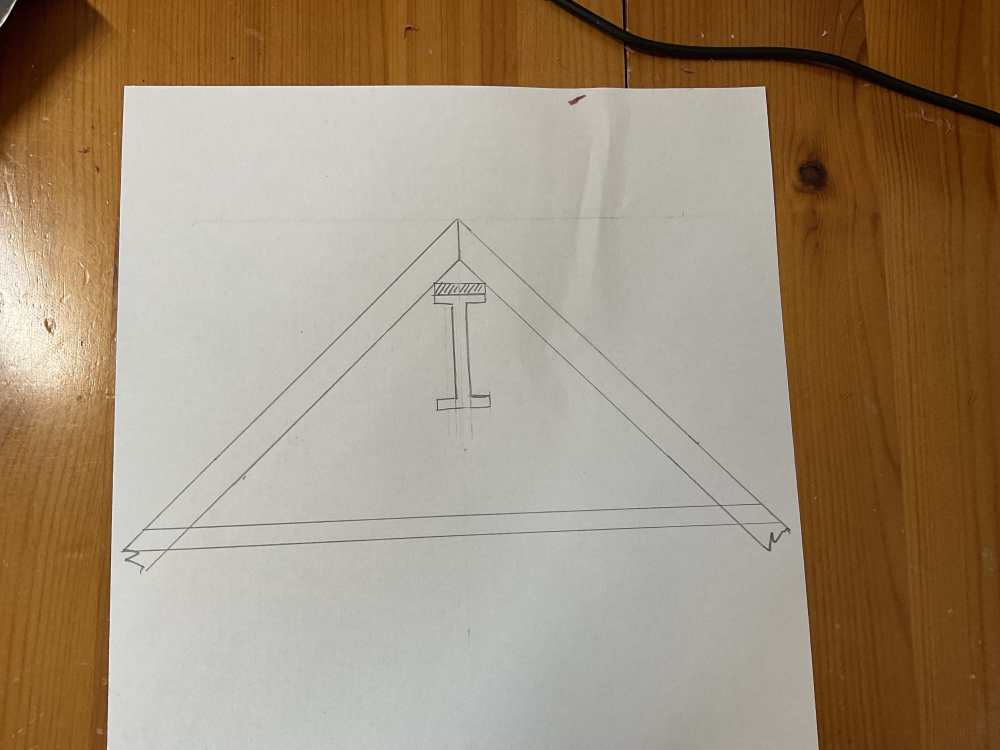

Further investigation has revealed this is the standard of construction I'm left to deal with!! That's the rafters siting on the ridge beam Having done a bit more research, I came across this suggested solution from an engineering forum: bearing on top of steel ridge beam -

Just realised I posted this in the wrong section so re-posting here... I wonder whether anyone could offer any thoughts on this connection detail please? The extension we have has a steel ridge beam to allow a vaulted ceiling. The rafters have been skewed to a 2" timber with what look like your standard nail gun framing nails. The timber has been bolted to the steel i-beam. Make-up is as shown in the picture below. The rafters haven't been birds-mouthed onto the timber but are just as shown. (The horizontal timber shown is a ceiling joist so doesn't extend from wall plate to wall plate and is about a 1.4m down from the ridge. Floor to ceiling is 2.5m) Any thoughts as I'm slightly concerned about the roof loading and restraint onto the steel.

-

Steel Ridge beam to rafter connection details

OldSpot replied to OldSpot's topic in Lofts, Dormers & Loft Conversions

Thanks all. Alas I fear that's exactly what might be happening 😡. -

Steel Ridge beam to rafter connection details

OldSpot replied to OldSpot's topic in Lofts, Dormers & Loft Conversions

Thanks Tommo, I wouldn't guess it but unfortunately it's already built (before we bought the property)! -

I wonder whether anyone could offer any thoughts on this connection detail please? The extension we have has a steel ridge beam to allow a vaulted ceiling. The rafters have been skewed to a 2" timber with what look like your standard nail gun framing nails. The timber has been bolted to the steel i-beam. Make-up is as shown in the picture below. The rafters haven't been birds-mouthed onto the timber but are just as shown. (The horizontal timber shown is a ceiling joist so doesn't extend from wall plate to wall plate and is about a 1.4m down from the ridge. Floor to ceiling is 2.5m) Any thoughts as I'm slightly concerned about the roof loading and restraint onto the steel.

-

Thanks both, that helps!

-

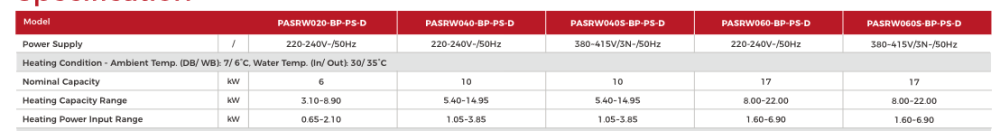

Can someone help me understand these figures please? For example, the first model says at an ambient temp of 7/6c and a water in temp of 30c and out of 35c, it has a nominal capacity of 6kW but it also has a heating capacity range of 3.10 - 8.90kW so can output more than the nominal by 2.9kW..? Presuming there is a direct relationship between Heating capacity and Heating Power Input? i.e Input = 2.10kW, Output = 8.90kW On the MCS product pages, they list an SCOP at different flow temperatures - what ambient temperature is this measured at and is there anywhere to see the SCOp at different ambient temperatures. How did you determine this James? Many thanks.

-

Yeah I agree James, it is a bit thin on the ground and requires significant searching to find anything! The "glossy brochure" has a bit more data.....(here) and includes the sound power level iaw EN12102 Just on the subject of noise: I see from the noise calcualtion that note 4 only extends out to 30m. If the distance to your neighbour is >30m can you account for the lower sound level at an increased distance? Common sense would suggest so but this is planning we're talking about!

-

Thanks both. Done a little more digging and they are made by Guangdong Phnix Eco-Energy Solution Ltd and appear to be the same ones as sold by Earth Save Products The MCS data ( MCS code BSI KM 748508/7 ) suggests an SCOP of 4.96 wi@ 35Cth a flow temperature of 35c for the 9kW one.

-

Came across these ASHPs recently and wondered if anyone had any thoughts on them? Ecoheat Superheat Seem pretty cheap but can't find any detailed specs for them?

-

Hi James, Thanks for highlighting this as it is thought provoking and forearmed is forewarned! Yes, but if your neighbour complained about noise and your ASHP install was shown to have the same or less noise than was required by MCS then it could be demonstrated that it was to an equivalent standard. I suspect the LPA would then be content and would be on shaky ground if they tried to take enforcement action. A court would also take a very dim view of the LPA if they took legal action without first trying to resolve the issue first. To do so would require the LPA to provide information on why they didn't think the install was of an equivalent standard. Backing this up is that the guidance to LPA's is that they should try to resolve the issue without resorting to enforcement action. In general, any action should be proportional and be in the public interest. Simply because an install hasn't been carried out by an MCS registered installer, without evidence as to why it was required, would I doubt pass these tests - especially if the LPA also failed to define equivalent. The guidance also says that action should not be taken if "there is a trivial or technical breach of control which causes no material harm or adverse impact on the amenity of the site or the surrounding area". So again, if the install has been carried out to a high standard then it is unlikely the LPA would have grounds for enforcement action simply because MCS aren't or weren't involved. Granted this is contained in UK Government guidance to LPA's but as with nearly all UK Government guidance, you should follow it unless there are overiding reasons not to. My final thought on this would be that if you could only install via the MCS Planning conditions route then there would be no need for "equivalent" in the text. By including it, there is an acknowldgement that there is another route but it is clearly up to the installer to ensure they do a proper job. So, as I started , thanks for highlighting this. It's likely that many previously believed you can simply install under PD without consideration which is very much not the case! Cheers.

-

Of course the MCS documentation is going to say it has to be installed by an MCS installer. It's a bit like car manufacturers used to say that you MUST have servicing carried out by dealer network to maintain the warranty and look how that ended.... I think the real question is what "equivalent standard" means and what an MCS installer does that no-one else is capable of doing? If challenged I think it would be reasonable to ask the LPA to provide information on what they viewed to be an equivalent standard. A response of simply saying it doesn't meet the MCS planning requirements wouldn't be sufficient because you wouldn't be declaring that it did, only that the install had been installed to the same standard and was thus equivalent to. If it went to court I would expect any judge to ask MCS to provide details of exactly what their registered installers did so a view could be reached on what equivalent meant.

-

Of course though, the rest of our UK tax system is completely even-handed!

-

used water softener: harvey twin tank worth a risk?

OldSpot replied to oranjeboom's topic in General Plumbing

Which Harvey unit is it? The ones I have seen (mainly S3/HV3) don't have that rotor with left & right on and have a slightly different layout on the top. I'm considering buying a Harvey so would also be interested in what the numbers in the boxes below "Service"; "Regen"; "Resin"; & "BV" mean if anyone can help. -

I bought a sink from Vieffetrade and they sell all manner of things. They're based in Italy but buying from them was quite a bit cheaper than in the UK - even when shipping was included. I was sligghtly concerned but the comms from them were really good and it arrived after a couple of weeks. It was well packaged on a crated pallet and was sent via air freight to us.