ruggers

Members-

Posts

316 -

Joined

-

Last visited

Everything posted by ruggers

-

Copper vs aluminum clouts for slate roof?

ruggers replied to ruggers's topic in Roofing, Tiling & Slating

He only specified nails. The hooks are very expensive -

Copper vs aluminum clouts for slate roof?

ruggers replied to ruggers's topic in Roofing, Tiling & Slating

No one could get me a price until the new year. Did you use 2.65 or 3.35mm? Cheapest i can get is £89 per 5kg of 2.65mm, which is a lot cheaper than online. Amazon is £82 but not sure what they'll be like. -

I'm having a slate roof installed on a self build, 400 centres, and I want to know if copper clout nails should be used or aluminum? The slates are 250 x 500mm 7 to 9mm thick. 38mm clouts required and 30mm for the eaves course. Aluminum 3.35mm or the roofer says if using copper I could use 2.65mm. I want the roof to last 40 yrs+ Some online reading says aluminum may fail between 20 and 30 years is this true? We're 3 miles inland off the West coast, there's a few houses around but we do get a bit of wind in winter.

-

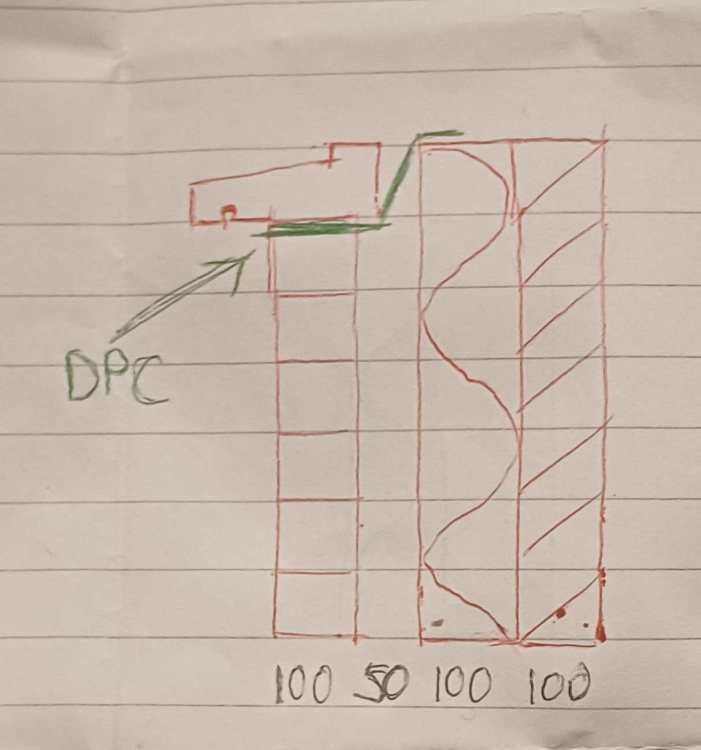

Yeah its creating a slip plane they say. So many methods people choose from, full mortar bed underneath, others spot bed them. Full length 100mm dpc vs full length stepped dpc. Small cut of dpc over the stooled top or not. Expansion foam between any joints if the cills are in 2 halfs. I'm not sure if this is a good or bad idea because the foam between isnt goijg to compress if theres mortar above in the joint. Some use a hybrid ploymer to fill the gap not mortar. The correct dpc detail and the centre pointing are the details i need to get right. These are being installed tomorrow

-

-

@Oz07 Thats what I was thinking but I wanted to see what others have done in case I'm missing something. The water cant get into the house because theres an open cavity gap.

-

As in 125 underneath the cill, up the back of it and then back over the top where the UPVC frame and cill sit over the cast stone? Any idea what the benefit of an external cill tray as opposed to just having 100mm DPC under the stone cill? My rear windows won't have stone cills , they'll be UPVC frame and cills direct onto the brick work with DPC or stepped tray underneath. It just feels like a stepped tray is going to prevent water escaping since theres no weep vents on a cill course where as a window lintel has weep vents every 450 horizontally.

-

The cast stone company won't provide details, they just produce them only and leave it up to the builders. I discussed two methods of installing cills I seen regularly and they said everyone has their own preference. This is what makes me unsure about the stepped DPC, because any water finding its way in from the outside into the cavity won't have anywhere to go, so it will just remain damp against the plastic tray. Why is a stepped tray needed when below the cill is open cavity, or a window head with cavity tray and weep vents? I have some expansion foam left from the brickwork, looks around 8 to 10mm thick but its knowing how far to set it down between the centre joint with them being in 2 parts and colour matching mortar pointed between them. I didn't know there was another option other than just using 85mm stub cill with a 70mm frame, The stone cill raised section is 40mm to bed the upvc cill onto with the frames fixed using window straps.

-

I thought of doing this it might limited the in coming air flow but could be better than nothing. What do the tiles or slates rest on, the over facia vent on the sub facia, and then the top of the capping board finishes in line with top of sub fascia?

-

I'm about to have my cast stone stooled cills fitted into the face brick exterior wall and I need to know if it's best to use 100mm DPC underneath, or a larger stepped DPC. What are the benefits if any of the stepped DPC as per my sketch? My partial fill cavity wall is 100 face brick, 50mm air gap, 100mm PIR, 100mm block. The cills are 65mm in height x 175mm deep so that i can have them set back into the cavity by 25mm, which then allows the windows to do the same. Rear of stone cill to front outer face of PIR=25mm. I planned to install a trimmed cavity closer under the cill, so a stepped angled DPC would interfere with this unless folded at 90 degrees.

-

@lookseehear hi, thanks for the detail. I don't think it works because the idea of the tilt fillet is to keep the slates right at the eaves to prevent them dropping, and also means the weight of the eaves course is on the timber fillet and not on the upvc facia. Adding the over fascia vent then puts the weight back onto the fascia rendering the tilt fillet useless unless I'm missing something obvious.

-

Thanks, I'd looked at this one the other day. I'll order some after ive checked the merchanta proce. Just wanted to check i was getting the good stuff and not wasting my time. Definitely won't be using it for any crimes @SteamyTea, some people are just evil.

-

Which brick acid is best for cleaning up any mortar residue off brick faces. Ive seen a few advertised as brick and patio cleaners but I'm wondering if they're too weak and i require a proper acid to dilute down. My bricks are new and are light grey. I have a few area where the rain caught it before it fully set, whether thats efflorescence or not?

-

Whats the best way to secure a 200mm horizontal soffit board and a fascia to 400 centre trusses. The rafters are 35mm wide and 150mm long on the untrimmed plum cut ends. Would I be better off installing a 150 x 25mm treated sub facia then add 18mm fascia or capping board over it for a better finish and more secure? I have 205mm soffit detail on the horizontal runs plus the gable ends. The soffit will butt up against the outer of the facing bricks as theres 2 courses of brick over the window lintels. What are my options to fix the soffit too? Would I screw a horizontal 4x2 to the side of each rafter 205mm long and then nail the facia into these? Or, fix a vertical 4x2 to the rafter with it up against the facing brick to nail the soffit into? This would mean nailing into end grain which isn't as strong.

-

What are my options for to vent my cold loft at the eaves end of the roof? I'm installing slates on my self build roof 35 pitch. 200 soffit. The ridge doesn't have to be vented but I'm looking to install a different ridge tile to the traditional vented ridge with visible rubber spacers. Because I'm installing MVHR which is going in the loft, I'm looking for as much air movement as possible for the summer heat build up. https://mayanroofingsystems.com/system/ridge/all-in-one/ I'm installing anthracite UPVC soffit and fascia and know that there vented soffit boards, but are there other options? I'd prefer not to have the weight of the slates bearing onto the fascia so a tilt fillet is likely to be used which rules out over fascia vents. I'd image continuous vented soffits attract a lot of dirt because my current white ones with circular vents are filthy every 2 years.

-

Thats a hell of a lot of screws per board compared to them guides showing 3 vs my builders none. I was thinking if both sides are screwed down too early, it would make it very difficult to get the next row t&g fit together and that it may be better to connect the next row in before screwing down each side of the newly glued joint. But this would mean once you start the job you have to keep going otherwise your screwing down boards that have set glue if the working time is 30 mins.

-

So thats one on every joists 0, 600, 1200, 1800, 2400. Assuming the 1200 and 1800 fixings, your fitting them on the opposite side to the 0 and 2400 ones but only after the 2nd row t&g are fitted to make it easier to pair them up and not be over clamped

-

How many srews did you put in a 2400 x 600 board? My guide shows 3 per sheet i thought it was 6. Ive 90 boards to lay.

-

Can you elaborate on the partially threaded screw so i can look for some. Not quite understanding why it would jack up? I thought 22mm boards would require a small pilot to get the screw started easier as they're quite hard but ive never used my impact gun on them. Nothing worse than cursing screws that wont start and end up with the driver head slipping into the fingers 😂 I had been looking at 4.0 x 60mm. Ill be laying them next week if its dry then exposed for 4 to 6 weeks. They are 60 day boards, no peel off, anti slip and protected both sides. @LaChab After you posted the Egger fitting guide, i looked for a krono fastshield one and it also tells you to fix the board on all 4 corners and 2 in the middle so I've no idea why their tech support said to just glue only. @Gone West what tape did you use, any old duct tape? kb-fast-shield-fitting-guide-final.pdf

-

Yes to this, also the perimeter edges are all exposed so would need sealed too with d4 glue or an alternative? Ive never used d3 or d4 glue, only pva and screws 15 years ago which was weather tight. No issues. Does a nail gun give the same pull down or would screwed be better, pilot drill and impact driver i could be following on behind as he lays them. Can't believe the krono tech advice and the linked above egger guidance says that glue only can be an option. Wind uplight could loosen them.

-

This is what i thought. I dont like a glue only idea. Tempted to fit them all myself. Do they need pulled tight with ring shanks or screws as the glue is setting or could i let him install them then follow on after he's gone same day or another day?

-

I'm about to install the first floor on my self build using Krono span P5 fast shield t&g 22mm boards and D4 glue. These are a similar product to caberdeck and egger protect for those unfamiliar with the brand. My question is, can they be installed with D4 glue only after the first row is mechanically fixed using screws or ring shank nails, or, does every board need fixed and glued? My builder who's installing them on this occasion, has said just glue after the first row because nail holes or screws will let water in. Is this ok, or cutting corners? I thought tape or filling the holes covered this issue. In the past i've always screwed as well but i do like to do things properly or belt and braces at times. I called krono for advice but the person i got didnt seem overly confident in their advice saying glue only should be enough.

-

Thanks Danny, I've started to install above lintels as you mention, but its sometimes hard to go beyond the width of the lintel due to the Cavity wall PIR & then where the external perps align. Becuse I'm using the T&G PIR I've been bringing it to each side of the lintel, then cutting it square. And in between the two square edge cuts over the lintel, I've profiled the PIR to the same angle of each lintel leaning outwards, then foil taping the the square edge joints. It helps minimise the cold bridging over the top of each lintel.

-

If you come down the wall 100mm with the AVCL, how do you D&D the boards to the walls with a perimeter edge seal. The board dab would then only be adhered to the AVCL at the top, not the wall?

-

@Nick Laslett Do you still use any kind of tapes or liquid membrane when going to use aerobarrier, or just use aero barrier only? @MortarThePoint How much passive purple did you use. Full walls, or just key areas or walls and joints?