Gus Potter

Members-

Posts

2142 -

Joined

-

Last visited

-

Days Won

25

Gus Potter last won the day on December 14 2025

Gus Potter had the most liked content!

About Gus Potter

- Birthday 09/20/1964

Personal Information

-

About Me

Signed up after having reviewed the questions, comments and responses. Very refreshing and positive. The enthusiasm and knowledge of the contributors to this site is infectious!

-

Location

Near Glasgow

Recent Profile Visitors

Gus Potter's Achievements

Advanced Member (5/5)

1.4k

Reputation

-

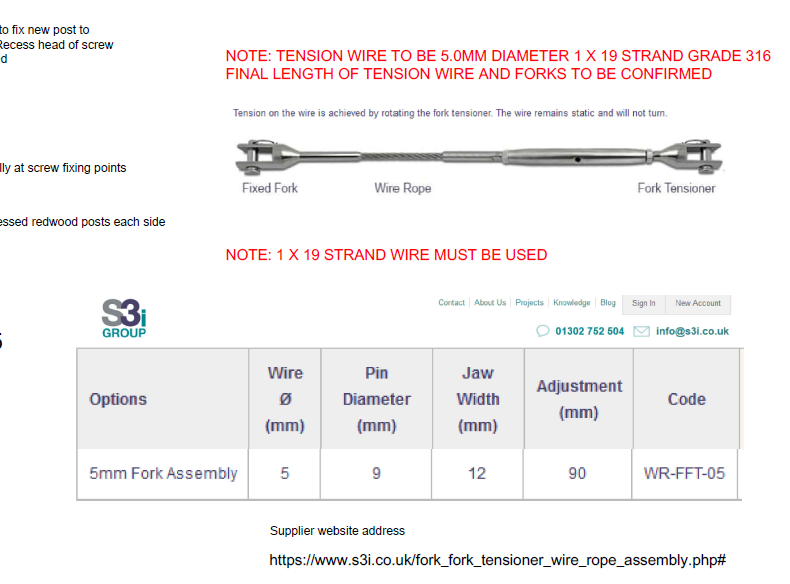

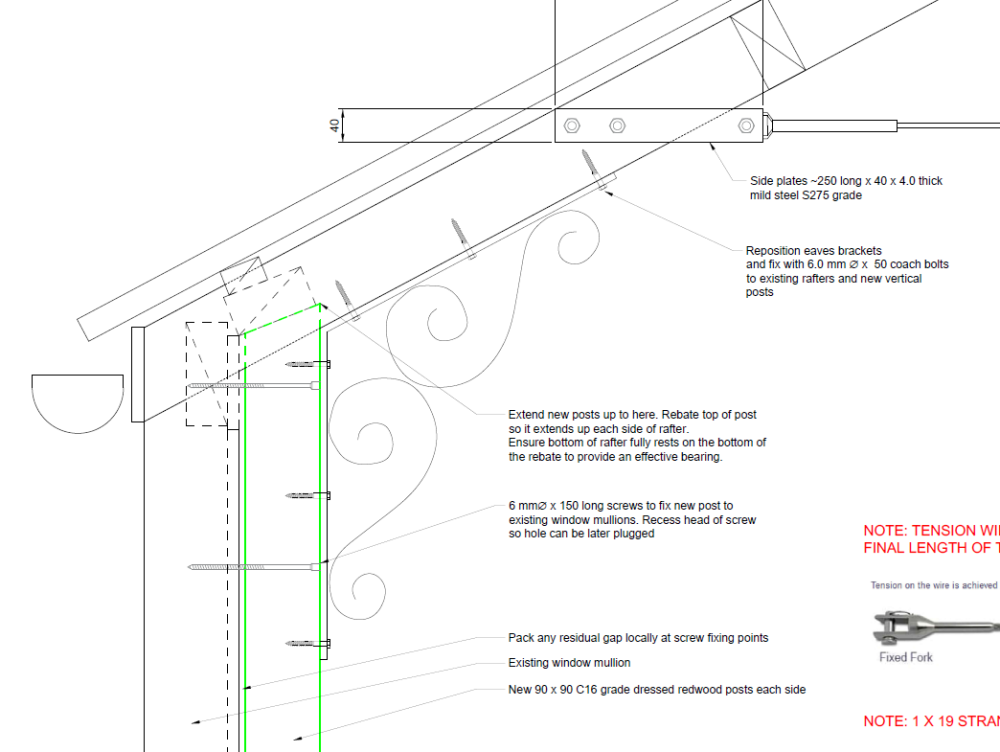

Ok to bring this into the domestic context. I upgraded a 1920's conservatory, to stop it falling down. It needed some additonal structural skeleton and some crack stitching ect. The glazing is irreplacable as it the brick plinth at the bottom of the glazing. The roof is a modern abomination.. but fixed that. The top bit cantilevers over the bottom and the steels were rotted and needed replaced. Hat off to the Contractor who managed to install new steels , do other stuff without cracking any of the glass. The above is a work in progress. But you can see I've put a new timber structure (supposed to look modern) inside and tied the rafters with wire and turn buckles. Below is a bit off the drawing for the tie wires I selected this wire as it has less strands, less flexible but stonger. The wire you see has a factor of safety of 5.0, some ropes you see often have a factor of safety of 7.. but for good reasons which I won't go into here. So @SteamyTea you are right, the designer needs to select a cable that has the best balance between strength and flexibility.. the more strands, often the more flexible. One strand can fail with less impact, but you generally get a reduction in over all strength with many small strands.. the reasons are complex unless you use a fatter cable. If I was designing a ballustrade say at around the edge of a balcony I would not use this type of wire. I would go for something with more strands as it's more flexible and workable on site, even if it is a bit less strong. A common offering is a 7 x 7 rope that has 49 strands. The rope you see in the example above has 19 strands. So do I. There are many that swear by a D4 rated glue.. but this is not a stuctural glue. The D relates to the durability primarily. It does stick things a bit structurally but I won't sign off D4 glue (unless it also has a structural rating) in structural timber applications for example. One default timber glue is to use something like Cascamite.. a resin glue that has been on the market, tried and tested over 40 years.

-

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Gus Potter replied to fatgus's topic in Heat Insulation

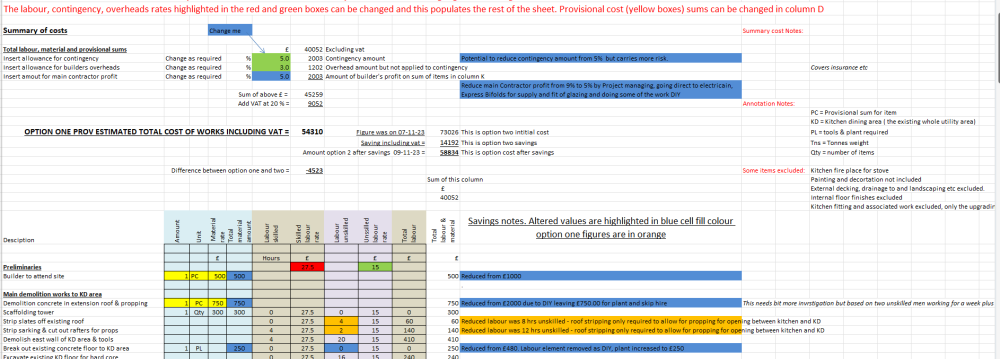

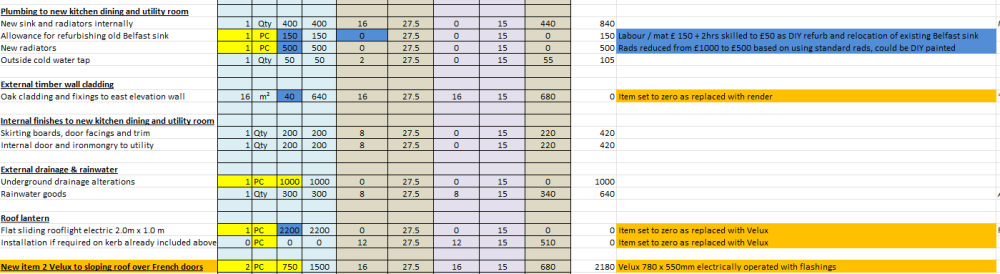

Ah, tongue in cheek. You can ask ten designers like me and get ten different answers. So long as each answer is reasoned out and evidence based then that lets you make an informed descision. Sometimes these descisions are based on you just saying.. we like and want that, yes we recognise that it may not be the best technically and SE wise, but we want it! So long as it does not fall down, leak water etc this is our choice and just get on with the design. This happens a lot. Ok, that is good. If you like a spread sheet then set up another tab for labour cost. What I'm leading you towards is this. When you design things you are aware that the Client has a budget. When I'm doing this I always have at the back of my mind that if I introduce complexity, design some steelwork say, that very quickly the labour cost can escalate. Insulation/ air tightness details can be very labour intensive.. and to get them right you need a level of site supervision. Builders will often get apprentices to stick on the tapes that you are basing a lot of your calculations on.. mistakes happen! Complexity also adds additional risk to the Contractor who has to make a profit. You, at the stage you are at, don't have the experience yet, but you can experiment, just using your common sense with a bit more research. Set up a tab that looks a bit like this. I made this cost sheet for a Client like you, to play with. And another part of it.. I hope you can read it as have screenshotted it. The labour rates are maybe a bit low now. The main thing to take away from this is to say for two site operatives you are looking at well over 2.0k a week, before profit etc, down south or in say Edinburgh you are looking at a lot more. My inclination is to look for where we can easily insulate, do the structure in a buildable way. If you take this approach it frees up cash to spend on the things you see and enjoy. What this does is to let you see how quickly the labour cost can get out of hand, but also make savings. If you look at the top bit you can see I have contingency, contractor profit and so on. If you just set up a tab like this for now you can add to it as you go. This is a bit of philistine stuff but you can have a look at commercial websites like check a trade to get a feel for labour and cost rates. You can ask your local builders, here on BH.. feed all of that into your spread sheet to get a reasonable rate for your area. In the round you need to strick a balance.. but with a bit of thought you can often get to install the things you love..call these a luxury item, if you can make pragmatic savings elsewhere. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Gus Potter replied to fatgus's topic in Heat Insulation

Ok lets look at some hard economics first, I'll assume this is your forever home. Ask your glazing manufacturer what their guarantee period is. Now in the past the adverts on tv said 10 years.. but now often in the fine print it's 10 for the frames and 7 - 8 for the glass. So you truck on with all your calcs.. but it could be that in 20 years time or a lot less your glazing is kaputt! So maybe it best to take the view that the least risk / long term value lies in insulating the things that are less likely to go wrong.. like the walls and roof. But what if you high end glass fails in year 9 .. it will be heavy.. lots of thermal stress and so on? You mention that you have some glazing at 0.73 W/m^2K. That is a very big ask.. is this a value for the glass or the window . doors as a whole? If so they are going to be very expensive. But you will be wasting money if you don't insulate the reveals properly. Someone is going to have to detail that and a builder is going to have to follow what is likely to be a detailed drawing. In doing stuff like this you'll also encounter what I call the half day problem. This is where you have to sequence the works to comply with a demanding detail. The operatives may only be required on site for a couple of hours and then have to get back in the van and go to another job.. all that needs to be paid for by you. Start with conceptually, windows an doors with an overall u value of 1.4 if in England and 1.2 if in Scotland. This will then allow a wider variety of suppliers. You are trying to refine the design too much at this stage.. you are leaving yourself no redundancy and this will come back to bite you in the arse cost wise. -

The national rules also say that local topography has to be taken into account. Your builder is likely having a laugh with you, are you in Scotland? Ok how do you fix this, or mitigate? Starting point is.. where do you live in the country? Also, how is your house orientated, can you post some elevations of your house so we can take a guess on how the wind might be hitting it. Is the house built on a slope? the shape of the surrounding ground and any nearby buildings can also impact. This is a bit of detective work.. you try and rule stuff out first. This problem may be confined to one elevation? Once you get a handle on that then it may be a case of just adding an extra flashing on one side.. minimise disruption.

-

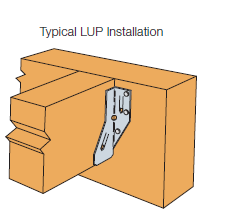

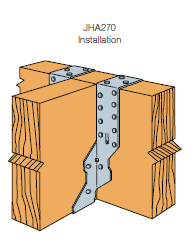

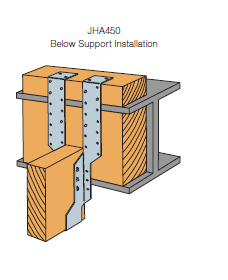

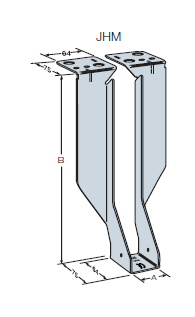

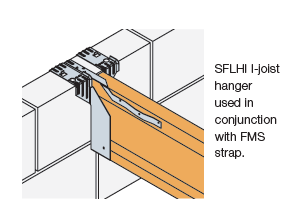

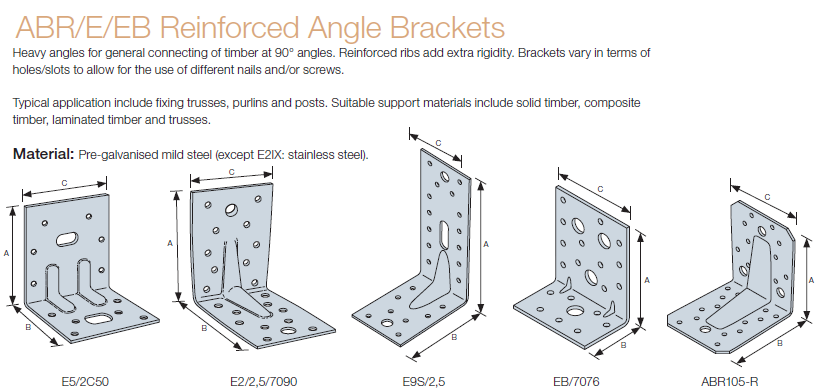

Hello all and for Hope this helps a bit. This type of thread crops up from time to time on Buildhub. How to fix (connect) floor joists to a wall? To make an informed decision you first need to go back and determine what the connections are supposed to do. Now the obvious one is that they need to hold the floor up under downwards gravity loads. These loads are the self weight of the floor and most often people, called the imposed or live load. However, floors often do other stuff. SE's know that a well put together floor acts as a big stiff beam in its horizontal plane (not its depth that you commonly encounter when sizing the floor joists) that can resist horizontal loads. It acts as (what we call) a diaphragm. They are kind of like a bulkhead in a boat that stiffens the structure. We use the floors to provide horizontal restraint to the walls and to shift horizontal loads to a place where we can more easily transfer the horizontal loads in the plane of the floor to the walls and then down to the foundations. Now as we commonly design for (and take advantage of) diaphragm action we first need to work out what the downwards loads are and then the horizontal loads in the floors that need to be transferred via the joist end connections. Once we know this we can then go about selecting the right connection.. and also know that if we swap out hanger connections and / or use resin anchors in place of another type of fixing say we are not going to do something that compomises the SE design. Here are some common examples of hangers: Below is what we call a simple face fix hanger, a joist fixed to a ledger. You can see that this is a light duty type of hanger. It can carry efficiently a downwards load. But it's not designed to carry much say left to right load horizontally. It's definitely not going to be great if the joist wants to pull away from the wall, joist tension. Below is something a bit more robust. This type of hanger is very common. These can also be face fixed but the image shows the hanger wrapped over the top of the ledger. By doing this wrap over we gain a lot of extra vertical load bearing capacity. You can also see that it may be a bit better if we want the hanger to resist say a left to right horizontal load. But again it will not provide that much joist tension resistance. So much so that the manufacturer does not bother giving a value for this. Below is something you also see on some floors. By inspection we can see that we could easily push the joist left to right and it is certainly not going to be able to take any joist tension. Below is a very basic typ of masonry hanger that gets build in. Note the tabs on the top are flat. This type of hanger requires a MINIMUM 3 COURSES OF SOLID BLOCK (675MM MASONRY) REQUIRED ABOVE HANGER WITH MORTAR FULLY CURED BEFORE APPLYING LOAD. This masonry above is to stop the tab on the top from unfolding and the joist falling down. You can see that it won't be that good at resisting left to right load or any joist tension load. If you don't have enough masonry above you can see if something like the below will work. Here the top tab is folded down the back of the masonry. This type of Simpson Strong_Tie hanger is also claimed to "The SFLHI has been designed to assist in meeting the air leakage requirements as part of the Code for Sustainable Homes. Since the joist is supported by a hanger and does not penetrate the inner leaf of blockwork, the potential for air leakage is reduced and avoids the time consuming and costly mortaring and sealing with mastic around built in joist ends." Also note that there is a short horizontal tie that provides some lateral restraint. Still not that great at resisting left to right horizontal loads though. Below is another option, different, but I often use these types of brackets as they work in all directions. Ok, that is a quick run down on connections.. but what about ledgers to use or not? Well if you want to use a timber ledger the main loads you need to know are the downwards load and if the floor joist to ledger connection is in tension, usually caused by a wind load. The SE design process for this is a bit iterative. First I look at the loads, then the joist spacing. The joists have some form of metal connection so you can't have a ledger fixing there. I kind of know what will work, if resin anchors then I'll usually look at a 12mm diameter rod as it's a good balance. Now for resin anchors to work you have edge and end distances. Roughly they need to go into the blocks but not too close to the mortar joints. You have to know where the horizontal mortar beds are and so on. To do this kind of design properly you need to understand how things get built on site, know what matters and where adding things to drawings can actually confuse the builder. You have to make the drawing notes easily understood by the builder. Usually in a dense concrete block most builders, if they follow the drawings can turn out something acceptable at the end of the day. But if you have a lightweight say Thermalite block you can (if the loads are not that high) still use resin anchors. But the installation procedure is more complex and demanding. The holes often need to be under reamed using a special drill bit for example. You need a dilligent and experienced builder for this and if you deviate from the manufacturer's instructions you will likely be in big trouble! Ok but have you checked with your SE that this is ok. Don't forget.. your builder and you are now making structural design decisions! Thus you are now carrying the can under CDM for example. Best to lift the phone for 10 minutes to your SE and get some assurance that what you are doing is ok.

-

Contract Administrator - cost queries

Gus Potter replied to Jothetaxi's topic in Surveyors & Architects

Agree. This is what builders and warranty providers use as a tactic to deny, delay and then defend. They know that often a domestic householder has limited funds. My approach runs in parallel. You do have to stick to the contract.. but you can at the same time introduce my approach. It works more often than not. As soon as you work it round to a safety arguement they often cave in.. the onus is then on them to prove otherwise as they have deviated from the design. For a builder or an Architect to answer some of my basic questions can be very diffcult, expensive and time consuming. My approach is to avoid this, you shift the battle ground. -

Contract Administrator - cost queries

Gus Potter replied to Jothetaxi's topic in Surveyors & Architects

This is not uncommon. Many designers have a list of builders that they trust to play fair. I have such a list. When I pitch for a design job I tell Clients I have a list of builders that may be suitable. I insist that they also get prices independantly and this avoids a later accusation of a conflict of interest. It also keeps my list of builders on their toes as they know I do this. I clearly state that I have no financial or otherwise interest in the builders on my list. This should be basic common business sense to any professional! Maybe the Archictect and builder developed a relationship after your job had started? This does happen, it's corruption plain and simple. But I can tell you that in my 40 years of doing this job I've only met one that was totally corrupt.. and he went to jail. 99 % of professionals are not like this. But many make mistakes, drop the ball, we are all human after all. Then their biggest mistake is not to own up early on, admit your error, deal with it.. if not very quickly things can get out of hand. Some designers may think.. well it's only a domestic job.. big mistake! You only have to look at the range of skills BH members have, yes they may be learning about building but many will pull your trousers down if you try and have a laugh with them. Here it gets complex as we need to look at the role that the Contract administrator plays. On a large contract they have a QS in support, who does the valuation of the staged payments. But on a small domestic project this is not often the case. Rather than referring to your Architect, I'll just say your designer. They will have a wide range of experience and depth of experience. To make progress we need to go back in time. Traditionally we would have a Clerk of works. Most often these were highly experienced trades folk.. seen it all. They were on site nearly every day and nothing got passed or covered up until they gave the ok. The contract administrator can in this day and age be expected to excercise "reasonable skill and care" and this is based on what they can see if they visit the site. If the builder has covered stuff up then this can be a clear issue for example. This maybe explains your expectation with your designers take on it. To add a bit of further context. I hold insurance to act as a Contract Administrator.. but my policy specifically excludes any Clerk of works function, as I would have to be basically standing over folk on site.. and there is a fee attached to that. If you refuse payment at the moment you must make sure you are not in breach of contract. It sounds perverse.. you have been wronged! But just check.. I hope I'm wrong! There is another way of maybe skinning this cat. Valuing work cost is a bit abstract. Even more abstract can be at times who decides and what is a bodge / unsatisfactory workmanship? The objective is to run up the clock to your contractor while introducing risk they have not forseen. You make their life hard! Here are some things I do: 1/ Contractor.. have you swapped any materials / changed the method of construction from what was shown on the drawings? Just write this and get a response.. then ask later if they admit to this... If so, can you show us where we approved that as we would have reasonable expected you to make us aware of the knock on effects. As soon as the builder does this then they are taking on a designer role and are now responsible for the design! Don't forget that you are a domestic Client and have an element of protection under the consumer act and CDM regs. Now even if they have changed insulation or air tight details that can put the structure at risk. You force them to prove that what they have changed or ommitted is still ok. By doing so you can shift the battle to your own ground. 2/ We are noticing movement / distortion in the finishes. Can you explain why we are observing this. It's on the face of it an open question.. but if they don't answer! The objective here is to turn a money problem into a building safety risk..condensation can impact on the structure for example and when you do that you often have them on the back foot. That's my take so far.. If you post some photos then I bet @ETC will bring his decades of experience to the problem! Then others will chip in! The question is.. Are you happy to walk away just now and call it a day or do you want to chase some form of refund? -

Full house renovation and retrofit guidance

Gus Potter replied to fisnik's topic in House Extensions & Conservatories

Good stuff! To me this is the key and will drive the design as you state. Forgive me if I come over as a bit blunt / appear to lack understanding, it's not my intention. Fundamentally you have your kids design requirements, potentially grand parents moving in.. (but unfortunately they will not be there as long as you and your kids) and of course your requirements. I very much admire what you are doing. I can @fisnik see that you want energy efficient home.. but there are different ways to skin this cat.. Ok, I've had a look at your drawings and visuals which look good. I'll outline my though process. Of course I know you have already put lots of thought into this but often and, this is the great thing about BH is that you get folk commenting.. they see things for the first time and come up with opinions.. sometimes they are wrong! If so that's good as it gives you confidence you are on the right track.. call it due dilligence. Other times they are right and folk realise they have dropped the ball! I've started by reading your requirements again and put my SE hat on first. A number of things flag up. 1/ You are creating a big open plan space on the ground floor and taking away a lot of the sideways building stability elements. This is to to with when the wind blows on the house and want to push it sideways. You'll need some steels in there to hold everything up above. One end of the steels is hard up against the party wall.. lots of vertical load and to stop over stressing things at the party wall is likely to entail a fair bit of cost. The steels will also need to be deisnged to stop the building moving sideways and as you move up the floors you also likely need some complex structure. There are other structural and costly things that flag up but I'm not going to detail these here for simplicity. But I can see many.. cost / build programme risks! 2/ Much of the wall arrangement on the first floor is offset from the ground floor which makes the load transfer more complex. There is chunk of the existing masonry wall at the gable left in place. Takes up space and is heavy. 3/ The roof is then a fairly complex shape and all that needs to be supported. Conclusion on the above. While I could design a structure to work for you I just know a few things deep down! 1/ I might feel guilty when I submit my fee! A structural design for this will need to be very detailed, with explicit instructions to the contractor. If it's not like this then the Contractor will go off and do their own thing and you'll end up paying for something that is not adequate. A very big dispute can easily take place. I can see that to make something like this work structurally is likely going to cost you more than you are aware of at the moment. Don't blame yourself for this, you have no way of knowing! 2/ You'll have to be able to make sure you are able to supervise the works and have in place an agreement as to how you deal with the unexpected. 3/ What you propose comes with lots of "Architectural risk" ( the Architectural details, potential for an inexperience Architect , or you are not paying enough for them to do this work) contractual risk = money and a potential huge amount of stress. You have enough on your plate and are already carrying lots of responsibility. I would encourage you to say.. let's try and set this project up to de risk it and aim to have fun doing it, then enjoy that quite satisfaction that you made informed descisions. 4/ Adding another story at the boundary ( lane side) could well entail strengthening of the existing founds.. work on that assumption for now to be safe. My next thought process: Good design is about iteration. You revist the earlier descisions you made to check they are still valid and you are not dropping a complete bollock. Unless you do this as a day job or have lots of experience in building then you can't be expected to know this. Below are some of my thoughts. 1/ We are looking for a house that will meet the main functional requirements. These are; your kids, two have special needs and one not. You have grand parents. Their old hips are going to play up if not already! The we have you and your wife.. this needs to be a home for you also.. everyone! 2/ You have a budget and want to make it as well insulated as you can, with modern ASHP etc. But if you look at what of the old house is going to be exposed it's actually very little? It's much easier to add a bit to the odd old wall and then increase the insulation more in the new bits. This is often the most cost effective and pragmatic way. What to do as a next step, even if to rule out and check you are making the right fundamental and financial choices given that you are learning as the design develops: My intention here is not to be patronising. I do this as a day job and can tell you that designs evolve as we gather more information and understand more about the constraints.. but in doing so often new ideas, stuff we have not thought about before comes into play. We in the day job get to change our minds often! A: Nuclear option. What about demolishing the house down to the foundations? That way you can probably save 20% vat. You get to start with a blank canvass internally, recreate the outside, make the structure simpler? I look at what you are trying to do and just know that to retrofit what you want into a 1930's building likely not to going to be a pleasant journey for you. The labour element is going to be high.. so you pay for that and the stress that will come with it. B: Retain the existing external walls on the front / rear elevation, demolish the rest internally and rationalise the structural design and layout. This will allow you to reconfigure the inside layout and make it more buildable and that could well save you money and it may well be quicker to execute so you get into the house sooner. I would want to examine this option in detail.. Architectural observations: I'll now put you and your wife first. You are working hard, I bet every hour you have is a prisoner! I anticipate that the attic bedroom is your sanctuary.. it really needs a small ensuite. The ground floor stair case is too narrow at first glance. I can see how you have designed so far on the basis that you are trying to fit / add what you require.. then have some fun with the heating / solar and so on. Lots of people do this. To summarise: If I was advising you I would choose this time to go back and review with you whether our internal design is still valid as per your post. I'm not saying you need to go back to planning. What I am saying is that I can see enough from what you have posted to warrant a comprehensive design review. I can see this from both an SE and from a designers point of view. I can see some scary costs from an SE point of view and even more scary when someone has to get the builder to do what you are paying for. I hope this helps.. even if you read my post and rule out.. it will, I hope, give you confidence. -

Interesting couple of days with the new heat pump.

Gus Potter replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

Some things to try just to rule stuff out. Ruling stuff out is a good way of approaching a problem. You have 185m loop. I would disconnect that and first gently connect up an air compressor to the return end. Gently blow the water in the pipe into a bucket, see if you are getting sediment and if so what kind. then blast it. That may be enough to clear any stubborn gunk. At least then you know if the pipe is clear. Then connect mains water to the return and back flow.. DO NOT do this on the flow side as you could make matters worse. Check the mains water inlet pressure and collect the water in a bucket. What is the pipe internal diameter you have? if you know that then you have some data on the loop that is maybe a problem. Now you can back calculate the loop characteristics. You can then reduce the mains water to a lower pressure and see what happens. Once you have handle on that you can then see what you may or may not have to do to the rest of your system. It could be that you long loop is ok, it just needs a good clean out! Remeber that as a long loop the flow at the return end would be diminished so gunk could have accumlated over time. Other question is.. did it work before you got your new boiler? Did it work fine when you first installed the system? -

Good question as an introduction. And this is even better! @Rick "Gus and I have debated this before. My position is you should design the loops to output the heat you need at very low temps. " "But I wouldn't deliberately add extra loops if it throws off your heat output calcs, etc. " I can see that my approach requires some reasoning in response to the very good points made by many (not just Simon and Rick above in response to my "philistine approach". I'm going to have a go at setting out my stall. I say from time to time that I did my first UFH a long time ago, long before BH and when is was almost for the "whacky inventor in the UK" To start as a bit of background. About 30 years ago I built a house out in the country. There was a guy (Clive) who was building a house about 1/4 of a mile away that had come over from Scandinavia with the UFH idea. At the time it was innovative in the UK. I looked at the complicated controls, could not be sourced in the UK at the time, even the pipe diameter and thought.. I'll simplify it, build my own manifolds out of soldered Yorkshire joints, got some pumps and a blending valve off the shelf and installed all of that into timber suspended floors, ground and first, all coupled up to an oil fired boiler.. basically a big blow torch in a twin walled steel box that had water in it. I could not afford "high end" but knew and believed in the principle of UFH. Now it worked ok but when it got really cold, which was quite often -5 deg over a week, often dropping to minus 15 deg overnight, I ended up having to crank the flow temperature though the UFH pipes up to 60 C. The carpets did not self destruct and the tiled floors hung in there! I learnt that floor finishes if slowly conditioned and installed properly are often more forgiving than you think. Incedentally my pal (Clive) down the road died and it was only about 5 years back that I stopped look after his widows system (500 m square house). It has twin LPG boilers, a low loss header and so on. Once I moved into my own self build.. could walk about with my socks off I became absolutely hooked on UFH. Make no mistake I love it and am a big fan. I'm not such a big fan of some of the stuff on BH.. it's too complicated! Since then (Clive) I've been involved in UFH, done some for myself and for Clients. The technology has improved a lot, especially boiler innovation, controls weather compensation and so on.. I've experimented on my own house.. tested ideas on my own houses, made mistakes. I've also learnt a lot about FE analysis, the maths behind it and it's limitations... and know it's to be taken as a modelling tool... although the folk that have a financial interest in selling say UFH .. it's designed by FE so must be right! That is bollocks.. it's a tool, a good one at times, but it must be sense checked. In my day job now I'm an SE and designer, still learning every day! Much of my work is domestic. I'm exposed to how domestic Clients work with builders. In this context take the money and Client / Builder expectation. These differer. Expectation of quality control on site differs, drawing and contract interpretation. On BH there are good comments about, testing, site supervision..and if you do this then you can have a leaner UFH design. But the reality is, from having done this for a long time, it is that what you think you are going to get as a self builder often does not get realised on site. The self builder is 95% often not to blame.. the industry probably is. 1/ My general approach: To digest this I'm going to split the UFH into two different elements and generalize a bit for sake of arguement / presentation. 1/ What is in say a screed / concrete slab or timber floor. If something goes wrong with that then the cost of access and repair is high and disruptive to finishes not least. As a correlation. Say I have my SE hat on, I design a timber frame and the windows have timber lintels on cripple studs. But the detailing at the cill causes hidden water to leak back into the kit, rots it and things start to move. That is often going to cost a lot to fix. If you then think.. well it's fair to ask the UFH pipes to perform for the same length of time as the structure.. 50 -60 years. To add more weight to this. What about your drain pipes in the house.. is it not fair to ask that they will also hang in there for 50 years? Or do you want your UFH pipe to last for say a guarentee period of 7 -10 years like double glazing units.. what about young kids that may later buy your house, is that for them to sort out, or inherit? Now know that in my first house.. 30 years ago the UFH pipes are still fine, not breaking down, getting brittle.. and that is with 30 year old pipe technology! Point.. is UFH like double glazing or an important "built in" part of the structure? Boilers, pumps etc above the floor can be easily changed. We may want to change them as more efficeint and simpler controls come on the market? 2/ What happens on site: I can see on BH that some are saying.. if you control the works, supervise, test, make sure you are draconian with the folk installing the UFH pipes, checking all their bend radius ( see UFH pipe datail), you have a fighting chance. Some on BH are asking about running UFH pipes over concrete slab movement / sawn joints, some say the UFH pipes can stretch a bit. I can tell you as someone who designs this slab / screed stuff that this is false prophecy as you are eroding the factor of "safety" and each time you do that you risk UFH failure. Your UFH pipes are not designed to be "stretched by concrete / screed movement or over bent! But the reality is for most self builders is that you are going to have to trust the folk on site.. and accept that some pipes may be bent a bit tight, stood on, overlapped and get crushed at the over lap. When laying screed or concrete the pipes should be under air pressure, say 6.0 bar, not just to make sure someone does not make a hole in them but also they expand by microns and this give them a bit of play at the return bends, prevents further stretching as a pipe is already stretched on the outside of the bend when it gets bent. The pipe manufacturer's declare their product performance.. but do not include your concrete / screed.. why should they.. it's your job to do this not theirs.. they need to sell pipe and fittings and are not liable for you concrete / screed design. Point.. your ordinary self builder needs to design something that can be drawn so the folk on site can understand what they have to do. Areas that are important need to be highlighted on the drawings. Pipe centres need to be the same. If the UFH drawings are presented in this way then Contractors will say.. that looks easy.. keps the cost down. You the Client will be able to identify any anomolies. Thus by all means use loop cad.. but think about buildability, the harder it is the more you will pay and maybe not get get what you think you are paying for. Now as an SE / UFH philistine and just having done stuff like this for a while. If you put in extra loops it covers you in part.. for shit that happens or a bit of dodgy pipe. If you look at the extra cost of using smaller loops its not that much. Say 15- 20% on the pipe install tops, clipping them and the extra length getting back to the manifold. It also means you don't have loops crossing concrete joints and so on. 3/ What happens when the UFH pipes come above floor level into the plant room: (a) More loops means a larger manifold, that is one of the down sides to my appraoch. Or you can say.. if in one room if the loops are roughly the same length connect them all together before the manifold as the flows will be roughly the same. You don't have to use the redundancy you have built in, it's just there if you need it. (b) Now since I started 30 years a go I can see massive innovation in control technology.. but it's very complex. But the big eplephant is the room is ongoing replacement part technology and now often the software that you need to support this. This can come at a scary cost as replacement part costs escalate.. it's the law of supply and demand. I have a Client that has bought a house recently that is filled with a fortunes worth of home automation.. he is ripping it all out as there is no manual on how to work it and the software is not updatable. I need to digress and reference @JohnMo John is an exponent of the open system that is compatible with modern systems.. This is incredibly elegant, clever, few parts needed other than an intelligent boiler. I almost think John has come full circle and back to how I started.. but in a more informed, evidenced based way and even more cost effective! (c) If we design at the moment on the least loops (using the least pipe and sod all other considerations) basis that are built into the structure then we are closing off our options for the decades ahead. Yes we will still have them but @SimonD that is partly what I mean by redundancy. The UFH design needs to be homogenous. @SimonD" I'm from the school of calculating heat load requirements in the room and designing emitters to satisfy this at a low temperature as possible and avoiding external controls as much as possible although I recognise and use room influence where needed. This approach does use the method of designing both radiators and ufh to the demand of each space." Simon.. that is OK. I can do that also.. but there is much more to the equation and that is why I'm trying to encourage folk to look at the whole life cycle. @-rick- I think and agree with you but you are only half way there in terms of what you do on a self build and how you can realistically control what happens on site. For all.. I've seen some commercial sites with UFH.. millions spent.. and they work even less better than many self builds! 4/ Use of software: Now I know that many on BH rely on software.. but there is nothing like getting a bit of basic knowledge to enable you to do a sense check. I'll maybe write another time about how you do that. As an SE I do some fag packet sums.. but before that I just look at the drawings.. you do the same with UFH.. look where the big areas of glazing are, volumes and where the building is more or less insulated. 5/ What are you setting out to achieve: Well you can be the theorist, look to save every penny on the gas / electric bill and treat it as a hobby. That's ok by me. But my experience is that that hobby will start to cost you more and more as parts become worn or software is redundant. My personal view is that UFH is still something that yes needs to function to heat the house.. but it's also a luxery. Once you have it you realise that the furniture is always warm.. if you have a leather sofa it's not cold, house plants thrive, the air currents in the house are less noticeable, your linen in the drawer is dry.. but not too dry, I could go on. But if you have a family member that is feeling unwell or you just want to have a hot zone then more loops make sense. You may change say in 20 years time the wal layout.. you want to make that easy. This is redundancy. You may be a doggy person.. always leave a cold spot! DSome folk want a traditional panty.. leave the heating out in there. You may want to sell the house in the future and the valuer turns up and says.. does you heating actually comply with the regs? You may just be wanting a UFH that works ok for you now.. look fancy and don't really care about any future owner? 6/ To conclude: I'm fully supportive of UFH. I'm not so supportive of folk that "design by calculation" alone. I can produce calculations that may show an element is ok, safe.. but that is not best design. Best design is about marrying elements into the rest of the design.. called holistic design. Here good holistic design is about getting the best you can out of the money you have. Self building is just that.. we get to have something you can't buy off the shelf. Some on BH are driven by calculation, trying to get a home that is most energy efficient on paper..the day after completion. I push back at this and say.. in real life say ten years down the road it is unlikely to work out the way you think at the moment.

-

Ah! .. as they say "recollections may vary" . Your enquiry is perfectly justified, evidenced based.. on their figures. It's a mixed bag. It's a fascinating / frustrating subject. Why can't they just give me a straight answer? I was in the past involved in bringing to the market cold formed steel portal frames. Testing and so on. Getting accreditation costs a fortune. A product supplier often has to balance the extent of testing vs how much of the product they are going to sell, the volumes, profit margin and so on. Once you can see under the bonnet ("unter der Motorhaube"?) then I think that UK suppliers are no worse / better than our European counterparts. I'm actually involved with a European supplier at the moment and they are exhibiting the same behavoir. At the end of the day if in doubt over size your radaitors. The radiator itself will cost more but the pipe work should be roughly the same size and the labour cost to install a slightly larger radiator should be the same or nearby. All the best.. but at the end of the day they have to look good, when you sit with your feet up and enjoying the fruits of your hard work.

-

If you have never played about with this kind of stuff before it is complicated. The main thing is to get a grasp of the basic thoery. The read round about, manufacture's data, BH posts. Sometimes you may think that it is even more confusing. But then go back to the beginning again and you'll find that things start to fall into place. You may have to itterate more than once. The read around concept is very helpfull as you discover other information that you can use on other aspects of the build, even if not applicable for the element you are considering. Keep talking to your builder and designer! Remember that they too may not have done something like this before. You will get there!.. and once you do and get something buildable you'll look back and often say.. well that was easy after all but it was a hard job to get to "easy". Also, you'll know once the job is finished that you ended up with a good solution.. quite satisfaction.

-

Ok many will disagree with me but here is my take on it. I did my first UFH heating system when many here were in short pants. I'm now a designer. My appoarch is pragmatic and absolutely driven by what is achievable on site, buildablity and cost driven. I honestly despair when I see folk trying to desing pipe layouts room by room! I can go on at length but it is complete bonkers! Thoery is taking over reality. To start. You are going to install pipes in a screed say and that has to be made as simple as possible. You want someone that is going to do this right, that is experienced and they will need a labourer. Take the experienced person at £300 a day and a good labourer that is going to uncoil the pipes and and not be a bit hung over, (kink them) at say at "£120.00 a day. So the labour is £420 a day. Save a day and that extra can get you more pipes.. for 50 years! Now to save labour and reduce risk its easier to make all the pipes at the same centres. Design for the nearly worst case. In real life the concrete guy turns up and may squash a pipe. You won't know. So you want some more loops as a bit of redundancy. There is a thread about how folk cock stuff up.. take my advice and avoid this scenario. Of course I'm not going to be BH angel of the month but best to be honest and give it to you straight about how things often work out on site for self builders. Yes you may think that you will be up to site checking everything.. but that is often wishfull thinking! Even then ask do you really know what you are checking.. do you have the experience / constructionknowledge to know how to argue if you find something wrong? At the end of the install you want something that has some contingency built in. But if you consider the labour saving vs the extra length of pipe it is a good balance of risk when you consider that the pipes need to last 50 years. As an SE that is used to balancing real life cost vs risk, and done UFH long before BH was even invented, I must say that much stuff you see on BH about folk trying to save a few quid is frankly complete pish! But it's not my money! My advice is to install plenty and easily buildable spare capactity in the floor and once the pipes pop up you can play with your controls to your hearts content. It's a good apporach as boiler and design technology develops.. to have spare capacity in the floor slab.. even if you don't need it right now. Put in plenty loops as a guard against the builder catching you out or say in the heat of battle you are doing the screed concrete your self.. you can easily miss a trick here. Don't think for a minute that while it looks great on paper.. on site when the concrete is coming you will likely not have the experience to say to the concrete guys,, hang on.. the may bully you and play to your wallet. So to finish.. I say to many armchair techy folk that are trying to refine UFH pipe layouts.. stop having a laugh and lets look as what happens on site and the labour cost of fannying about with different pipe spacing. Many folk on BH end up moving walls or end up with a diferent kitchen desing layout. Self building is hard enough without getting over enthused about some hot water pipes in the floor.. keep it simple and that way you'll save on labour and reduce you risk of something going wrong. That's my view in the round.

-

Interesting couple of days with the new heat pump.

Gus Potter replied to MikeSharp01's topic in Air Source Heat Pumps (ASHP)

That length of loop is bonkers! But if in the floor it is what it is. Question is.. is that loop near an external wall or not and if so.. by how much and is the cold wall on the upside of the loop or the cooler side? Next is does this matter? I know many are not keen on my rough and ready approach to UFH. But they will realise 5 - 10 years down the road when they are spending hand over fist to keep it working! or maybe want to sell! Now if you look at many posts on BH there is my view on a high reliance on software.. but pretty much none on BH know how that works! they blindly trust.. they certainly don't know that FE models are and often widely wrong. As an SE Fe is subject to lots of scrutiny as it often down right dangerous! The IStructE has many papers on this.. it's a great tool if treated with caution, a very handy aid! Ah but there is an upside. The first thing is to recognise that we have not lost the skill to be able to teach ourselves. When I went to uni at 40 was in tears on my first day.. I clocked that my educators were actually teaching me how to teach myself! You can only appreciate that when you go to higher education in later life. Yes we are a bit slower.. but also faster as we have the life experience to be able to identify what we need to learn in the context of the problems we face. Mike: Is the black line your actual room temperature? If so that does not reflect real life? What room was that in? -

Ah, that is a bit embarrassing. Fault lies at my end.. I should have explained in a better way. Blame is being a bit harsh on yourself. Ask and reflect. How much were you expected to know when you started? Evaluate how much you have learnt, take pride in that, and yes don't let it weigh on you. I'm making some posts that reflect my own experience. From a novice self buider to an SE / Designer that chips in here. I've made some horrible mistakes when running a contracting business! But at the time I did not know any better, I just did the best I could with the knowledge I had at the time. Now this thread is about.. hind sight and mental health to be blunt.. but also about trying to see how you get out of the woods at times when the world turns to shite. I'm chipping in as I am fortunate enough to see it from both sides.. as a past self builder myself and now on what you may call "the other side of the fence".