-

Posts

474 -

Joined

-

Last visited

-

Days Won

8

Everything posted by Omnibuswoman

-

I have noticed that the bottom of the metal shoes holding the ends of the I joists are slightly below the level of the joists themselves. I'm shortly going to be plasterboarding the ceiling, and wondering how to overcome the difference in depth. Should I cross batten the whole ceiling to create a level surface, or shim the face of each joist with something of the same depth (around 4-5mm), or just not worry about it? I've noticed that if I screw PB into a surface with a raised point it makes stress noises - what I don't know is how much this matters....?

-

Low points: and how to get out of them

Omnibuswoman replied to ToughButterCup's topic in General Self Build & DIY Discussion

Thanks all for the supportive replies. This forum is one of the best sources of support a self-builder could have. I want to give special thanks to @BotusBuild and @Fallingditch for their generosity with both practical and moral support, and to @Gus Potter, @Nickfromwales, @ProDave, @SteamyTea, @ToughButterCup and others who have responded to threads and direct messages with advice and wisdom that I could not have managed without. Knowing that you guys are here, and willing to show such kindness and generosity with your time and knowledge, is invaluable. -

Low points: and how to get out of them

Omnibuswoman replied to ToughButterCup's topic in General Self Build & DIY Discussion

I was drawn to this thread as I was badly struggling for motivation in the couple of months before Christmas, especially trying to undertake tasks single handedly that really required someone with 8 arms, and a lot more height and strength than I have. I eventually got to the point where I was barely achieving anything, and getting more and more self-critical and fed up. Constantly tired, frustrated, and aching. I decided to speak to my GP and started taking anti-depressant medication, which has made a tremendous difference already. In addition, I decided to take up the offers of help that people have given me, and aimed to structure activities around that help in a way that makes it feel the most effective, eg. getting some large boards up on the wall with a few screws so that when I'm back to working alone I can do the simple task of filling in the remaining screws. It isn't even slightly surprising that the pressures of undertaking a self building project can have a negative impact on mental wellbeing. Even the most optimistic of us can get worn down by the feeling of it being relentless and interminable. Asking for help can be transformative.- 106 replies

-

- 10

-

-

I don't have green fingers, what to do?

Omnibuswoman replied to Post and beam's topic in Landscaping, Decking & Patios

You might consider getting a digger and driver to scrape the very top layer off, or scrape it into a bund at the edge of the garden. This should even out the ground and pull up the scrub. We did this, but then left it untended for a couple of years and the brambles did unfortunately return. It takes a number of years of continuous work to get brambles out permanently. -

Does aerobarrier negate need for airtightness detailing?

Omnibuswoman replied to SBMS's topic in Ventilation

That’s a great result! -

I have been out to see what the finish looks like… when the porch was built (recently) the guy squirted some foam under the window and added a strip of trim (possibly an offcut of a composite decking board from the look of it). So, the question is should I get the foam gun narrow tip and squirt in some expanding foam from the inside to stop air ingress? Thanks, M

-

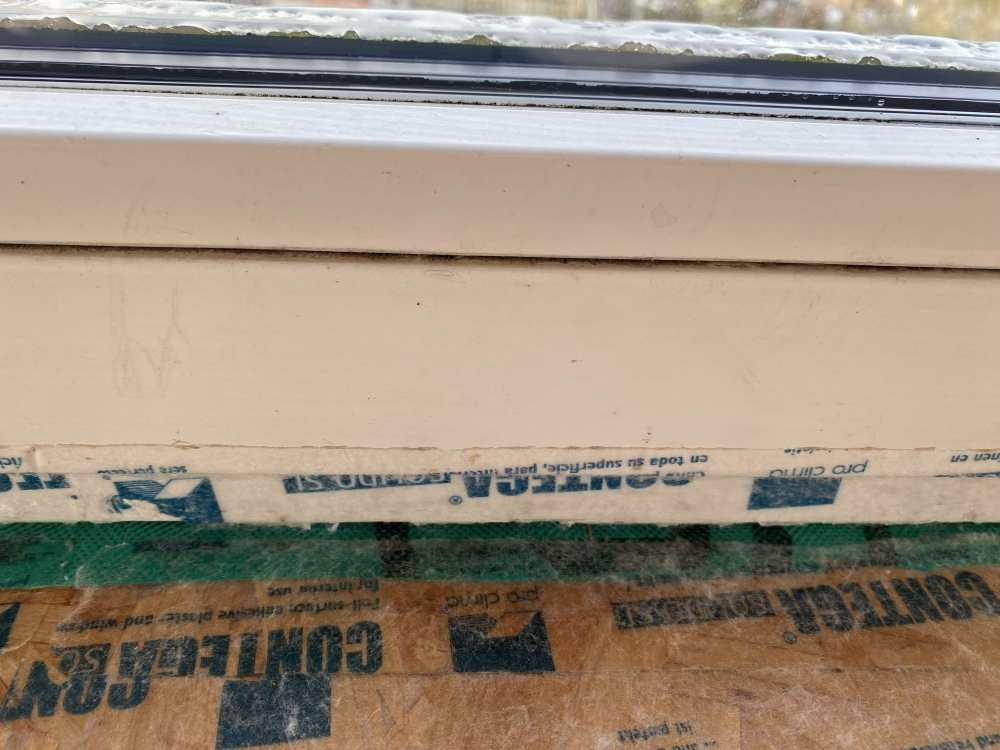

Thanks @BotusBuild, @Iceverge, @Redbeard and @Nickfromwales for your replies. Botus is right, the MVHR is not yet commissioned, and the humidity in the house sits around 65%. We use the German method of 'shock ventilation' regularly, but the humidity remains relatively high as the area we are in has a rather damp climate. The house has been heated for the last year and sits around 20-21C almost all of the time. I've been closely monitoring this recently via a Shelly H&T, and found that it fluctuates very little with the lowest reading being 19C. In answer to the questions: @Nickfromwales, I'm not sure entirely what you mean by thermally broken... the window is a non-opening one. I also suspect that there is foam missing from underneath which is why I was mulling on the option of injecting expanding foam beneath the frame, however I was worried about potentially trapping moisture and making the problem worse... I will go outside tomorrow to have a look at it from the outside. There should be a strip of compraband filling any gap beneath the frame, so I will look for that. The window also has a lead skirt outside of it as the porch roof sits just below the bottom of the window. It may be that this is acting as a cold bridge. @Redbeard the OSB is only on the inside of the window frame. It doesn't cross the thickness of the wall to the outside. The OSB feels damp, but I think that is from the condensation on the green fabric. I will investigate further tomorrow and report back. @BotusBuild, I will give you a shout if I need a second pair of eyes on the issue, thank you

-

We recently noticed a build up of mildew on the air tightness tape at the base of our largest window (triple glazed, aluclad, 2.2 by 2.3m). The air tightness tape felt damp to the touch, but without any clear cause. I have just cut through the tape to see what is happening behind it. There is a layer of green fabric that laps under the window which the air tightness tape covers. The builders used this green fabric to weatherproof the house -it sits on top of the timber frame beneath the wood fibre board insulation. The green fabric strip under the window feels very cold and possibly damp, and the air tightness tape overlying it was damp to the touch. Is this interstitial condensation? Is it possible that there is cold air coming in under the window, and creating condensation on the tape where it meets the warm air in the house? If so, what is the solution... should I inject a bead of expanding foam on top of the green fabric, underneath the bottom edge of the window frame, and then seal it back up with airtightness tape? Or should I go outside, and investigate what has been done on the outside of the frame when it was installed? Photos attached. The first photo shows the mildew on the tape. The second photo shows the bottom of the window frame after I pulled off the fabric of the air tightness tape (I couldn't remove the adhesive layer), and also shows the green fabric that comes in under the window. Many thanks...

-

Welcome Jonny. Looks like an exciting project. I found Cornwall planning dept to be very reasonable and pragmatic. Good luck with your application. There is a wealth of encouragement and information here in the Buildhub forum - now is a good time to have a read back over previous posts/threads before things start to get too busy for you!

-

I would echo the above with respect to Openreach - we had ongoing problems for about 6 months with BT trying to establish a connection. The Openreach fools engineers turning up, assessing the job as needing to go on the 'too difficult' pile, and making excuses not to do it. I made a complaint to the Chief Exec of BT, and this got me a complaints handler who persevered like nobody's business to see this through. In the end, the connection was made. The heroes engineers that did it accidentally gave away that this one had been in their office for some time, and no one wanted to do it as it was hard. At the end of all of that palaver, we received over £700 compensation (the statutory amount per day), which paid our broadband bill for more than two years. In the interim, we were using an EE 4G dongle which worked really well, despite the 4G signal here being a bit iffy.

-

Laundry room sink / appliance plumbing wobble…

Omnibuswoman replied to Omnibuswoman's topic in General Plumbing

-

Laundry room sink / appliance plumbing wobble…

Omnibuswoman replied to Omnibuswoman's topic in General Plumbing

Thank you! -

Laundry room sink / appliance plumbing wobble…

Omnibuswoman replied to Omnibuswoman's topic in General Plumbing

@Nickfromwales I have now removed the pipe and am planning to turn the corner and bring it along the hallway wall instead of the laundry side. You mentioned using two 45° bends, rather than a 90° - is this to turn the corner more gently and reduce the risk of blockages? Any other advice? Thanks! -

Laundry room sink / appliance plumbing wobble…

Omnibuswoman replied to Omnibuswoman's topic in General Plumbing

Thanks. I will have a look at how far along the hallway wall I can bring it before it comes through. I could maybe disguise it by building out the lower part of that wall as a little shelf feature. Watch this space!! -

Laundry room sink / appliance plumbing wobble…

Omnibuswoman replied to Omnibuswoman's topic in General Plumbing

Thanks @Nickfromwales I should have explained more…. the upstand is only a temporary thing that allowed us to use appliances before making the laundry room up into a proper utility space. The plan is to have a four-unit sized (roughly 2450mm) run along the laundry room wall with dishwasher (later to be replaced with tumble drier), washing machine, sink unit, and fridge. I shoved the upstand in last year just to allow us to have use of the dishwasher and washing machine. My plan now is to take that out, and fit a proper sink P trap with double nozzles for the two appliances in the final location, as HWMBO is fed up of swapping over the two drainage tubes every time we use the appliances. (I’m also doing the incoming water connections to allow both appliances to be connected at the same time instead of swapping them over, which is what we have been doing.) The upstand location is 1550mm from the R hand wall, which is essentially where the middle of the laundry sink will sit. The fail in my plan was to buy a McAlpine sink trap, which I now find won’t connect with the existing Flo-Plast pipework, and that is what I was looking to BH’s hive mind for. Having said all of that, I appreciate your plumbing wisdom, and wonder if you still think the waste pipe is too high if it is only connecting to a sink P trap and not having the upstand in place? Thanks!! -

Laundry room sink / appliance plumbing wobble…

Omnibuswoman replied to Omnibuswoman's topic in General Plumbing

This is the other side of the wall, under the half-landing. The plumber set the first 400mm of pipe coming out from the soil stack, and I took it across from there, and then through the wall. Where the waste pipe joins the washing machine upstand the top of the pipe is around 500mm off the floor. (This was my first ever go at plumbing, so please don’t judge too harshly!! 😳) -

Laundry room sink / appliance plumbing wobble…

Omnibuswoman replied to Omnibuswoman's topic in General Plumbing

Thanks, yes when I first did the waste run I realised that the plumber (who had put in the soil stack and a nominal piece of waste pipe) had used solvent weld pipe, so the push fit fittings I had bought had to go back to SF to be changed for solvent weld. When I bought the washing machine waste upstand pipe fitting, which is a compression fitting, I was surprised to find that it would fit onto the solvent weld pipe. The sink waste with the double appliance nozzles is McAlpine. This won’t connect to the existing solvent weld flo-plast pipe. -

Today I decided to start to learn plumbing - cue a very frustrating day with some comical moments. I’m at the point of changing the temporary appliance waste upstand for a sink P trap with double appliance nozzles where the laundry room sink will go, and have hit some difficulties: Stoopidly I didn’t realise that each brand of plumbing parts are slightly different in size, so the McAlpxxx trap won’t connect to the Flo-plxxx pipework. I’m also uncertain about how to arrange the connection of the P trap to the incoming waste pipe. Photo attached of existing waste arrangement. (The end of the horizontal pipe sits where the sink waste needs to go.) The Flo-plxxx double nozzle P trap also gets appalling reviews and isn’t sold at SF. Is there an alternative brand that will connect to the Flo-plxxx 40mm waste pipe? Any suggestions how to configure the sink waste to meet the horizontal pipe? thanks!

-

Actual vs nominal door lining depth

Omnibuswoman replied to Omnibuswoman's topic in Doors & Door Frames

Thanks - no I didn’t get an answer to this, so had filed it under “things to deal with later”. Very helpful to know. -

Getting there, and time to sell up

Omnibuswoman commented on BotusBuild's blog entry in South East Cornwall Low Energy build

Very well done to you both. You remain my inspiration, and valued source of “been there, made that mistake, here’s what I learned” advice. Looking forward to having a G&T on the glorious gin balcony! -

I’ve heard that Totem timber in Plymouth is good for straight wood…

-

Advice needed on French drain

Omnibuswoman replied to Omnibuswoman's topic in Landscaping, Decking & Patios

No, we didn’t have any problems with water, this was just part of the original plan for the house, to protect the foundation slab. Shillet tends to have water sit on it a bit, then it will drain away given time. -

Advice needed on French drain

Omnibuswoman replied to Omnibuswoman's topic in Landscaping, Decking & Patios

Thanks for your replies. This is the description given in the quote: This doesn’t describe the pipe having a sock or being wrapped. However, my understanding was that it is simply part of how a French drain is installed. We did discuss the pipe being wrapped in membrane when he came to quote for the job. The ground is shillet, which is a sandy/stony type of soil.