tommyt

Members-

Posts

37 -

Joined

-

Last visited

Personal Information

-

Location

NW Essex

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

tommyt's Achievements

Member (3/5)

7

Reputation

-

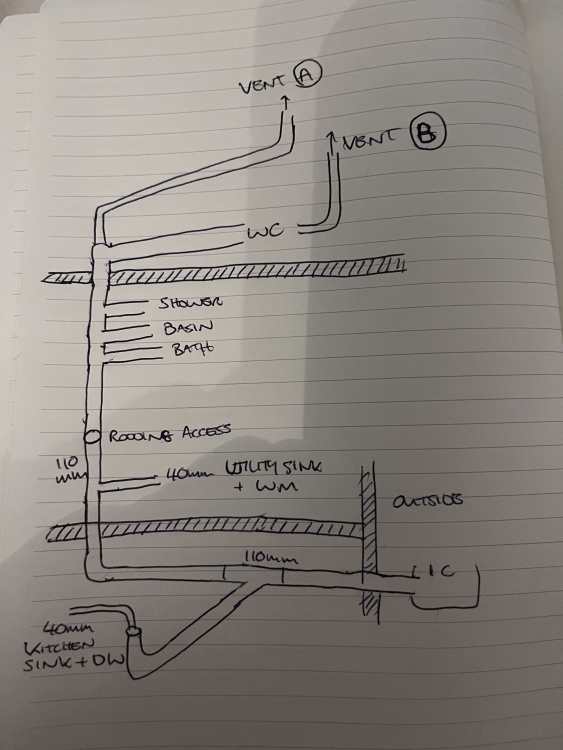

Pondering my waste pipe vent connections. Only place I can go out is above the bathroom. All bathroom wastes except WC will go down into ceiling space and connect in the utility room below. the WC will be above the floor to the corner of the room where the 110mm can come up through. Just wondering if I can have the vent after the WC connection (B) or continue it up where the branch to that pipe is in the corner? Also can the vent be 50mm or will I need to make it 82mm Also the kitchen soil pipe has been put on a y branch under the B&B floor so assume it won’t need a vent as it’s connected to the same stack that will get a vent? please see fag packet sketch

-

I have a fairly wide in places trench to fill in all around the house that was excavated for the foundation. Want to put a couple of French drains in the uphill side of the house as rainwater is collecting here. And I need to leave room for surface water pipes nearer the top. What material should I use to fill in with? There are a couple of areas, Front Door, Garage Entrance, Patio and Heat pump slab which also will need a solid footing under them. I have plenty of spoil saved from the excavations so can fill the further away from the house part of the trench with this. Was thinking a vertical geotextile membrane to seperate and build up in layers?

-

Brilliant thanks. I’ve stuck mine on. Hoping it will pull out easily enough after.

-

Ok I see. Was it not stuck to the walls, did it all pull out or tear and leave some behind?

-

Thanks. How did you cut the foam to below the surface level?

-

Didn’t know if to put here or UFH forum. I’m having polished concrete floor and am after a flush finish to the patio over two lots of sliding doors. And also the front door. The doors are installed on compact foam. The frames will end up partially buried with 12mm protruding above FFL I’m struggling to work out a neat way to add the 10mm expansion strip along the door frame. If I leave it level with the frame and cut it back after I’ll see the top of it. If I leave it shorter than FFL there will be a very thin piece of concrete above it liable to cracking. anybody have any ideas or photos of how you’ve done this before? Can I do away with it in front of the doors?

-

Install of Harvey twin water softener - initial set up problem?

tommyt replied to oranjeboom's topic in General Plumbing

Hi @oranjeboom I think the manual suggests filling with water manually to start because the water can sometimes be orange from the new resin before you flush it. Filling it manually prevents the orange water going in the salt tank and you thinking there is a fault. 1) Sometimes a manual Regen is only a half Regen and may take an automatic Regen to reset itself. 2) Which pipe is dripping, is it the 3/8" pipe going to waste? it shouldn't drip at all and if it does could be the cause of high water usage. 150Litres per person per day is the calc people use but I find even that is a lot these days. 3) Yes the brine will always be above the plate unless in first stage of Regen where it sucks it out. The water will become fully saturated with salt and not disolve anymore unless the float fails and it overflows somewhere. It is normal for one block to go faster than the other. -

Homewater(Harvey) H20 water softener developed fault

tommyt replied to spaceman's topic in General Plumbing

To add, this is an easy (and free) test you can do if the resin doesn't come out then yes the shuttle valve would be the next point to check, Is the water still soft when the flow is low?- 12 replies

-

- harvey

- water softener

-

(and 1 more)

Tagged with:

-

Homewater(Harvey) H20 water softener developed fault

tommyt replied to spaceman's topic in General Plumbing

Hi @spaceman If you look at both vessels they have an oval shaped plug held in with 2 x 1/4 hex head self tappers. Take out the vessels from the tank as this could get messy. If you isolate the water supply and relief all pressure in the machine by performing 2 turns of the manual regeneration screw on top of the meter. Then open up these vessel plugs. You should see resin (tiny orange beads) about 1 inch below neck. If resin begins to pour out like lava from a volcano then the resin is shot and has to be replaced by the manufacturer. Resin is easily damaged by chlorine/bleach and will expand so may have only affected the vessel that was online at the time of the problem.- 12 replies

-

- harvey

- water softener

-

(and 1 more)

Tagged with:

-

We hired an architect and he drew plans

tommyt commented on Thorfun's blog entry in West Sussex Forever Home

I am in the process of sorting this out on my site and received confirmation from the EA that you don’t need have to have a permit to discharge from them if you can meet the general binding rules and get building regulations approval. If you believe you can’t meet the rules, then yes you will need a permit. -

You can always install a water softener. Never did a site visit where I couldn’t find a way to get one in. (FWIW softener waste discharges at mains pressure so can be run a fair distance, even vertically to a waste pipe elsewhere and we often built insulated cabinets to install them on an outside wall) But sometimes it isn’t a straight forward job and the price or the disruption needed to fit one was too much for the customers to swallow. People always seemed to make the decision to install one after their house or brand new Kitchen was finished.

- 199 replies

-

- hard water

- water softener

-

(and 1 more)

Tagged with:

-

Cracked around the back bearing by any chance?

-

I always use Loctite 55 on brass to brass threads. Brilliant stuff. And WRAS approved.

-

Yep, this ?? Is the way

-

That’s the way I do it but just use a small off cut of board to draw the profile cut needed on the back of the board to be cut