marmic

Members-

Posts

113 -

Joined

-

Last visited

-

Days Won

1

Everything posted by marmic

-

afternoon all........ we're currently close to this point too......... any conclusions before we open a can of worms and talk with BC/insurance companies. Difficult to find official answers but from what I've so far found theory is we would need a temporary certificate to satisfy insurers before occupation. At the point we plan to occupy will just be kitchen and bathroom basin outstanding internally (will have sink with hot and cold water in utility room) so can't see that being an issue. We can have temporary cooking facilities easily (transferred from the shed we currently use!). Level access to front door for docM will be the only outstanding item preventing sign off by BCO - can't do this until ground dry late spring/summer. look forward to any further thoughts and opinions please and hopefully where to find official answers.......... worst case scenario we'll just occupy unofficially for now and when bco turns up just tell him (and insurance) we're just getting it ready if the question comes up. many thanks........M

-

stainless steel screws for chestnut cladding / decking etc

marmic replied to marmic's topic in Building Materials

I looked at these but only A2, they also offer A4 with a slighty different [deck version] - but decided the square/robertson drive not for me with more chance of camming out - albeit will probably 'stick on the bit better' and perhaps look a little nicer -

stainless steel screws for chestnut cladding / decking etc

marmic replied to marmic's topic in Building Materials

-

This might help if anyone else searching for stainless steel screws for chestnut cladding / decking etc in what I found to be a significant minefield with massive cost and clearly quality differentials! A good few hours down the pan! Eventually found these and placed order today - proof will be in the pudding so no comments on quality etc as yet but feeling quietly confident. So not a recommendation - let's hope it will be................ You can also speak with a normal human who knows what they are talking about! https://www.endurastainless.com/stainless-woodscrews/decking-screws---countersunk-stainless-steel---torx-drive/decking-screw-countersunk-torx-tx-drive-stainless-steel-a4-marine-grade-316 also very interesting: https://www.fastenerusa.com/blog/tell-screw-stainless-steel?srsltid=AfmBOoogzyXC-QceFYTVxyxBdILjVskzH34yHohaOgi9x-y49Rw3NaQG

-

Recommended method for connecting 40/50mm wastes to a soil stack

marmic replied to Annker's topic in Waste & Sewerage

i will be interested to see replies as we'll be doing something similar soon - eveything into one stack / drain. A tip I've been given is to have a dedicated waste pipe from shower to avoid the trap being 'siphoned out' and a lovely scent entering the bathroom! -

Payment Terms - Pay everything upfront?

marmic replied to Mulberry View's topic in General Self Build & DIY Discussion

On supply and install contracts there's no way I would agree to pay everything up front - has to be something left on table. They do have to balance their risk too of course. As JohnMo said it's a two way street - they want your money probably more than you need their services. But ensure agreed in advance - don't negotiate later. No names but a number of suppliers were crossed off my list just for being unreasonably demanding on payment terms - problem is most people tend to be compliant and do as they are told - and many companies know this. The sooner everyone gets a bit tougher with these types of suppliers the better! One company (not windows and doors) I recall was demanding unreasonable payments and also wanted the most ridiculous contract I've ever seen signed - straight in the bin. Was a throwback to 80's/90's double glazing! Appreciate us self builders have less clout than prinicipal contractors, but the PO in my book has to be the primary contract and usually is. Thankfully we're now at the stage of smaller packages and day rates with local trades we know and trust..............and then it will be lots of DIY weekends for stuff that can take longer................ if you haven't commited already strongly suggest talking to Simon at Nordica. They can supply the same product. -

no opinions?? a rare event !! .................. 😀

-

ps - my work wednesday is getting ducts ready etc - electrician pulling the cables (design/supply/install/certify)

-

Morning all, Not the correct department to post in but something up with website not enabling some to be selected! As ever because we are doing something a bit different to 'normal' have another conundrum so todays question requiring opinions/answers/thoughts etc please - don't be shy: We have flexible ducts into plant room entering through floor for incoming electric main, STP, RWH, PV, external lights/power, data. (Only holes in walls are for ASHP/MVHR - must avoid any more for various reasons including passivhaus high performance). Suddenly feeling twitchy as some of these ducts finish outside above floor level - thinking possible water ingress over time, or am I overthinking this? We also have ducts for water (RWH already in and future main) but these terminate underground at low level so they are fine The one directly next to house currently out of ground I'm currently thinking cut back a little to slightly above ground level and seal with foam + silicone once cables in. Is this correct? for data cables the duct end will be higher but will terminate in adjacent outbuilding which is above ground built off piers - so not concerned there about water through end of duct, but will still seal up open end to prevent insects/rodents. But what about where it's above ground for a short distance and where it enters ground and in ground - is there a risk of water entering over time if chewed by rodents for example? Albeit will they actually chew it as no food source there - thinking probably not as we are currently using same sort of flexible pipe for a temporary grey water drain at ground level and not been touched. for the incoming main (which is my main concern): Large armoured cable running from green box (with meter) about 60m away. This will just be laid on ground parallel with and tight to hedgerow (covered in brush and stable mucking out to prevent it being seen and theft) and will gradually sink. Where it turns away from hedge to house it will then enter duct (higher than floor level) which then goes underground for the last bit of it's journey. Do I carry on as planned and seal up the end, or do I need to dig a hole where duct currently disappears into ground and cut it underground below floor level and seal it there? STP/RWH lower so no concerns there. I need to decide what to do ready for Wednesday - day off employed work to get ready for second fix electrics commencing next week, which includes pulling cables........ many thanks...........M

-

if only we'd had the room! electric oil filled radiator and large bills, and electric blanket of course! Albeit once we're finally in the house we'll use very little energy - in theory...............

-

evening all from a rainy Kent - here comes the mud again! Hit a conundrum! We commence battening Monday and was about to finalise an order for sweet chestnut horizontal cladding couple days ago - decision had been made back in summer to to use a rebated feather edge. BUT, having picked up the samples again noticed couple splits at rebated end - a section 'peeled off' easily with some small blotchy dark marks in the split. So now concerned about stablity and possible diseased trees from this source? I won't name at this moment in time and am due to speak with them Monday - they have a good reputation so may be able to continue as planned if explainable - but my confidence isn't good at present so going back to the start reviewing options again. We have to use sweet chestnut (as discharged planning) and horizontal The reasons for the decision to use rebated feather edge was visual preference of feather edge but being rebated overall thickness less and sits flatter, and as long as machined at slightly increased moisture content (probably nearly therre again now) it can be racked up without being concerned about expansion gap. Also a sustainable source. Normal feather edge might be an option, but due to how I've detailed fascia/barge/corners it becomes a headache / may not work - and subject to wider boards in sweet chestut being available for window reveals - albeit could use cladding and joint, but would rather not (windows set back - passivhaus) Shiplap (angled or scalloped) was no.2 choice - thicker too so perhaps more stable, but I'm now concerned about the thin machined sections for the T&G joint. But sample does seem robust. Has an expansion gap built in (to joint) so can just be racked up. Half lap - thicker than rebated feather edge again and simple rebates leave thicker sections than shiplap which is feeling far more comfortable - but expansion gaps need to be left. I don't have time to do this myself and we don't want to add risk - the chap who will be fixing for us is more than capable, but I've learnt through the process of this build to keep things as simple as possible as people aren't always as careful as I would be. 1. am I missing any options? 2. any experiences with different profiles / sweet chestnut please? 3. any supplier / product recommendations? 4. any any general opinions out there please? usually is !! 😆 also with the different profiles the old question of how to fix, what with (stainless for sweet chestnut regardless and predrill), and the old 1 or 2 fixings debate! many thanks...................m

-

or pallets and old rubber stable mats 😁

-

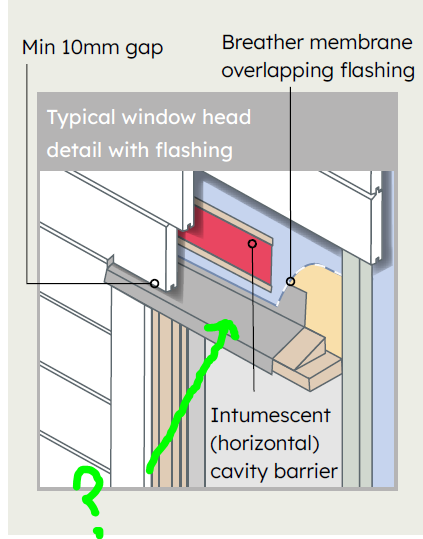

flashing over windows and doors - timber cladding

marmic replied to marmic's topic in Building Materials

many thanks - was thinking that as a possibility if I couldnt find a more purposeful trim and already have a roll here....... I did same on a garden office (posh shed!) few years ago at last place but wrapped it down over and stapled to the front edge of the reveal board (which were gravel boards!) - not sure how well it will withstand UV / full exposure etc. -

hello all, anyone know please if a preformed flashing like this/similar is available off the shelf from anywhere? so far not found.......... (25mm vertical battens + 21-25mm horizontal cladding/reval boards). ideally anthracite grey to match windows and roof. or if not best/easiest/recommded thing to use? be interested of course to know what others have used please................... many thanks

-

https://www.thehealthyhome.uk/

- 15 replies

-

- 1

-

-

- passivhaus

- technical

-

(and 1 more)

Tagged with:

-

for planning stage design we followed passivhaus rules of thumb and submitted old school pencil drawings and statement (by me - cost was a huge amount of time!) and stated passivhaus, but didn't state certified. Once planning approved we then developed design further and paid consultant to run through phpp and we were bang on. We are hitting passivhaus high performance but not quite certified level however (wouldn't have paid for a plaque anyway!) which I had anticipated - simple reason form factor as we are only single storey app 100m2 - as JohnMo states form factor is important. yes the theory is use phpp at planning, but with some common sense and careful thought I didn't believe I needed to - which I didn't.

- 15 replies

-

- 1

-

-

- passivhaus

- technical

-

(and 1 more)

Tagged with:

-

thank you - have just spoken with Tarkett - they have advised expansion gap is required...... shame, but as expected. back to glue down for me!

-

looking quickly (before I run out the door to catch a train at last minute to do what I'm meant to be doing!) can only see click and glue-down. Am I missing something? https://home.tarkett.co.uk/en_GB/collection-C002723-inspiration-classics

-

highly unlikley to be going anywhere imo - but that really doesn't help! Where does liability sit / calcs? Hopefully somebody on here can advise/suggest further. Assume no structural warranty? (they can be picky). Ours is very similar albeit with an addtional run straight down the middle under a structural spine wall in line with ridge. We used SE - design was almost the same as I had thought but very slightly deeper. Without SE calcs etc we wouldn't have got past our BCO / structural warranty provider

-

I don't know the answer but I would personally ask SE who designed the foundation - if they say yes (covered by their PI) and provide written confirmation BCO will I believe have to accept.

-

Sent them a polite and simple email (out of working hours) asking for a call** to discuss this particular product. So instead of calling they replied by email with no name (extract below in red - polite but astonishing - basically asking me to contact them again and do what I don't have time for) - to which I responded 'I shall look elewhere then.......' Nothing since - they don't care! Perhaps they think we're just browsing for fun and won't actually be spending money on floor finishes for a whole house? ** An approach I have taken quite often throughout the build process to save a lot of time and also narrow down companies that can be bothered. In some cases has also clearly been a good approach to provide some confidence they know what they are doing, or not! Particularly the larger packages / supply and install. Sometimes emails are of course more appropriate / preferable. I reckon on average when I've sent enquiries to a number of companies for the same thing: A third don't respond or want you run around after them A third respond but clearly haven't read the brief and/or don't know what they are doing often offering something we don't want/need With the final third being the narrowed down options - who we end up spending money with! Maybe it's just me, but I'm astonished so many businesses these days must lose out because they can't be ar#ed! I have to work for a living (construction industry) - if an email like this was sent out from the office of the company I am employed by I would not be happy! Rant over!! Thank you for listening!! 😆😃😁 Thank you for your message and your interest in our loose lay vinyl flooring. We don’t currently arrange outbound calls, but we’ll be very happy to help you by email with any questions you might have. Please let us know what you’d like to discuss, and we’ll provide all the details and guidance you need. Alternatively, you’re also welcome to give our customer service team a call directly if you prefer to speak with someone — you can find our contact number on our website. Kind regards, Your BRICOFLOR Team

-

sounds good, maybe too good - I shall dig deeper. Anybody had experience of this type of product please?

-

thank you. response from simply bamboo below - which is very much what I was expecting (but didn't answer about glue down section on website not showing anything. not sure how glued down product moves however - probably flexible adhesive, but imo can't then be bonded well). You’d need expansion gaps for any timber, no matter how its fitted. LVT may be best.

-

Architects have messed up. Next steps?

marmic replied to flanagaj's topic in General Self Build & DIY Discussion

Tpo map?