-

Posts

793 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Adam2

-

So after 4 years my rooflight seems to have stopped working it's FAKRO DEF-D U6 10K 100x150 so that's 1m x 1.5m electric opening that has integration to ZWave for home automation. Symptom is that the green light adjacent to "P" button on the window is always on and the other button (should be a manual up/down button) ) has a light which will briefly flash once if pressed long enough. Does anyone have any suggestions for troubleshooting beyond what I have done so far: power cycle, random presses on the 2 buttons??? I did call re support and the cost, please sit down, is £300 + VAT for a call-out charge plus the cost of anything they need to fix it. So I guess you can see why I'd like to explore this if poss before starting down that line but expect it is likely the eventual outcome.....

-

That's why I like this forum, always people volunteering to help.

-

I have a cooling unit that has intake/exhaust passing through an exterior wall (original post mentioned the chiller but not the plumbing for it). So the wine room challenge is preventing the room heat warming it up mainly in the summer as in the winter it should be OK with an external wall and good insulation and no UFH of course. Whilst I could lower my room/house temp the summer this will anyway by >22 degrees (which I like - maybe should move somewhere warmer)

-

So we'll go with double glazing - as we are planning to keep the cold in vs out. I guess that when specifying this glazing panel I should specify the inside as the outside so any heat retention aspects to the glazing will work more effectively? Another aspect I'm pondering is the best way to make the door reasonably air tight. possibly using the small wings along the long edges and a soft foam strip along the top. BUT, for the bottom of the door could a drop seal work well for this, or is there a better solution seeing as I'm not looking for fire prevention just minimising air movement.

-

Fridge isn't big enough, it'll look very nice and fill in a hole under the stairs that has been gathering useless objects 🙂

-

@Roz My experience from the new system was very positive. I had a pro-forma with no VAT number from a tile company (that went bust) for 9K and they accepted this, I did provide a justification and provided their VAT number that I found via the internet. Maybe I was lucky but am pleased I did this. If you are being genuine and have some evidence - inc proof of payment if needed (I was not asked for this) then I would be surprised (based solely on my experience) if that would jepardize the whole submission

-

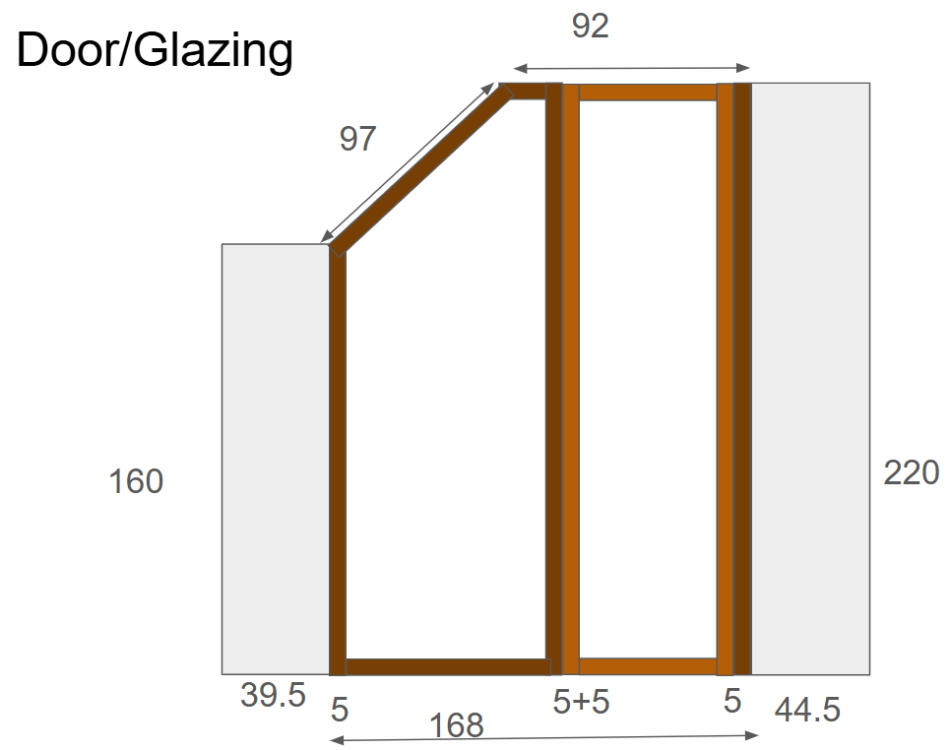

We're finally at the stage where we have a trusted chippy to build the under stairs wine room. The area has no UFH and the ceiling and walls were extra insulated. There is a chiller unit installed which should work down to our target temp of 16 degrees - getting lower temps meant a much bigger investment which I'd like to keep for the wine 🙂 Front will be along these lines: The front of this will be glazed with wooden framing (sapele stained to match our stair edging detail (door shown on right but will be the same colour). To minimise the warm air leakage into the wine room I am thinking to have a drop seal on the bottom of the door and use magnets to hold the door closed against a thin rubber strip set into a rebate that the door closes against - using a simple pull handle to open (happy to hear any other suggestions on this also) Our house is fairly toasty as I WFH and like to wear shorts most of the year so internal temp is not often below 22/23. So - pros/cons of 2g vs 3g: Cost is not much different Weight is a big difference and moving the large panel in 3g could be a bit of a challenge (approx 1m x 2.1m) Weight may also make the door frame a bit of a challenge if we are trying to keep thinner framing as shown So I guess my question comes down to is the insulative benefits in this scenario of 3g going to make much difference?

-

-

Render or texture paint on cement board cladding?

Adam2 replied to philcvk's topic in New House & Self Build Design

Sorry for the delay - but yes we did this no problems - -

-

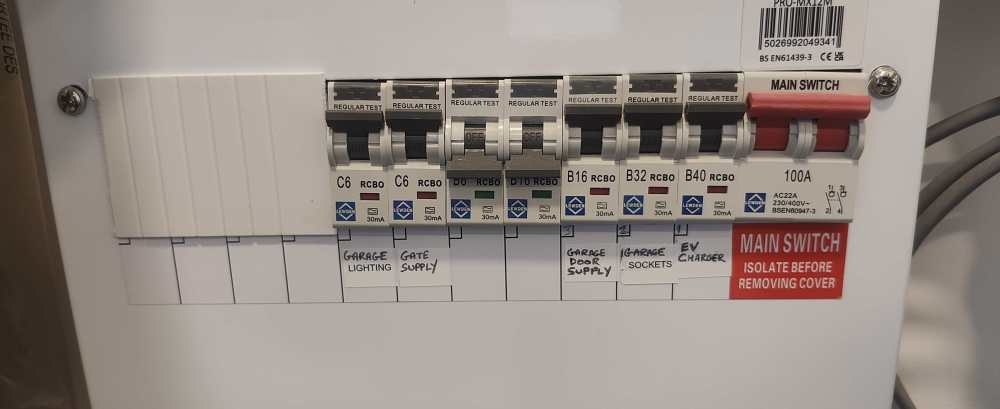

As I have my own company owned EV I can apparently pay for the charge costs from my company which is v nice. Unfortunately I have a a very basic charger so wanted to find the easiest way to measure the usage. Is there something I can use in the consumer unit or should I find an old elec meter and install that in-line? My EV charger runs from a small consumer unit installed in the garage which seems to have some unused capacity.

-

ICF for a large detached garage - in the right forum!

Adam2 replied to graham-l's topic in Insulated Concrete Formwork (ICF)

Lots of questions come to mind - just finished an ICF house that I managed the build of. Cost - is this very important to you? Maybe other options will be cheaper? Insulation - Yes you get this with ICF but not in the floor or the ceiling (usually). if you really want this to be insulated curious why - if there is no heat source the temp will still drop/rise just more slowly so unless you use it for working in and have a heater then a high price for something that does not seem to provide much benefit. Not insulating the floor would be a big omission if insulating the walls and ceiling but would mean more groundworks unless you can just build up from current ground level and have a sloped entrance? Security - if you go with ICF you won't need rebar for security - if someone comes equipped to go through 150mm of concrete the rebar will not be a problem. No idea of the risk level of course but a timber building also has eco-crudentials and I would have thought you could get something up v fast. If you wanted insulation then maybe consider SIPs. Render is fine on ICF - JUB is on mine and seems good but others I'm sure are OK also. Flat roof - someone could easily get on top and in 5 mins cut out a space to jump down and probably open the door of your storage area etc - so your Ferrari will be off to the parts shop I'm not anti ICF just not enough info to know if it seems right for this purpose vs other options. It is appealing in that you can do a fair bit of work yourself but you could get a good carpenter in and go sail your boat 🙂 -

We're going to build something like this We'll have a 20mm thick base and header mounted on floor/ceiling but would like the slats to be rotatable. Thinking of something like a sprung push pin (not sure of right terms here) at the top but can't find anything that will depress say 15-20mm to make install/removal easier vs really small travel ones. For the base ideally soemthing that will allow rotation - not like it needs to be spinning around so just some kind of locating system for it to be held in place - the slats will be 2.9m long and I think weigh less than 10kg each so does not need to be too industrial - ideally we'd have the slats looking like they touch the floor Push pin Appreciate any suggestions for parts to make this work well

-

Core drilling 200mm concrete wall - what kit required?

Adam2 replied to BotusBuild's topic in Concrete

Here it is -

Core drilling 200mm concrete wall - what kit required?

Adam2 replied to BotusBuild's topic in Concrete

-

Core drilling 200mm concrete wall - what kit required?

Adam2 replied to BotusBuild's topic in Concrete

Also recommend paying someone. I had similar - all 200mm concrete with a lot of reinforcement a good guy can do quite a few holes in a half day. For mine he bolted the drill to the wall - maybe he could have used a stand for the drill but a few were quite high. A bonus is that the cores are super smooth and with a bit of varnish make a nice ornament. Will post up from my phone 🙂 I've some decent extra long 20mm bits for small hole requirements and they actually work better than expected as long as rebar is not in the way -

TV Wall - maybe consider a TV set into a fabric covered wood frame. You can more easily increase size if you need to and can also have speakers set behind the fabric so can provide a nice looking solution with some flexibility

-

I have an invertech which has been running fine but this eve the water is 23 with setpoint 45. Unit is running but not heating water. It is set for both got water and heating. Not aware of any time limits on heating the water. Any suggestions of what to check as thought would start heating water as a priority. Thanks

-

well no dust but plenty of water coming through the table when cutting - it's cold out neighbours can close the windows

-

Thanks all - in the end I found a Rubi table saw for a bargain locally so have that - did a test and even with the blade left in it it cuts cleanly through the 20mm tiles 🙂 Only issue is the amount of noise this is going to make, my neighbours probably thought I'd finished making a racket!

-

I've laid all the full tiles on my terrace (on pedestals) and now about to attack the edges - the tiles are 20mm porcelain 600x600. About 30 tiles to cut. I'd like to get a non or very minimally chipped top edge - what should I use for this? I understand the cutting disc is really important and I need a wet cutter. Would a simple table like this https://www.toolstation.com/vitrex-power-pro-750w-wet-tile-cutter/p82003?store=LQ&utm_source=googleshopping&utm_medium=feed&utm_campaign=googleshoppingfeed With a decent blade like this https://pureadhesion.co.uk/rubi-porcelain-tile-diamond-rim-machine-blade-cpc-180mm-30955/ be up to the job? Or do I need a big machine like this https://tools4trade.co.uk/products/excel-1250mm-wet-tile-cutter-bridge-saw-240v-1200w?variant=42311376273605¤cy=GBP&utm_medium=product_sync&utm_source=google&utm_content=sag_organic&utm_campaign=sag_organic&srsltid=AfmBOoo12F815X3zguW7QZLU7TscCY51PE_vmPOLbFPYaUAjtbeUW5wJGE4 which maybe I should rent? I guess a blade that comes down into the tile face may mean a cleaner cut? cheers for info

-

I had similar but it was the LED bulbs used in a bedroom ceiling. Thought it was my automation boxes causing a small leakage current but was fixed by changing the bulbs - I guess some bulbs have a "feature" that does nothing with any very low level current? Maybe a quicker thing to check?

-

Well, maybe. The aim is to KISS 🙂 The ASHP / Buffer config is a setpoint of 34 degrees (thought was 32 as per original post) with a 3 degree differential. Meaning the UFH should be getting water in the range 31 to 37 degrees. I'll take the setpoint down to 30 and see how we get on. My concern with going lower is really just the time for the UFH to start having an impact. The room stats are all in the plant room so have remote probes in vented wall mounts Balancing - using self-balancing actuators so think this should be OK unless there is some other balancing you have in mind.

-

OK so seems the simpler model does not allow external temp probe - which I need. Issue is the larger one does not fit a standard back box - which I need. So....still looking for a low temp differential (0.1 or 0.2 degrees) simple timer that allows an external temp probe and fits a regular UK single back box - let me know if you have any....am continuing to Google of course but nothing yet