-

Posts

56 -

Joined

-

Last visited

Everything posted by OwenF

-

Firstly, glad you found my link to BGS useful. Welcome to the exciting and detailed world of engineering geology. On the above, it’s is geologically impossible for sandstone to form above a Holocene clay. Therefore your ‘thin layer of sandstone’ is 99.9% a cobble. Ignore it for design, but factor it for digging. That SPT (incorrectly labelled CPT) is refusing on the cobble E.g. 50 blows for 15mm. So other than the SPT of 7 shallow you don’t have any insitu data. The U100 results would be useful, but unlikely to be attached to the log. I haven’t digested every detail of this thread, but I suggest (as others have done) you find a SE and get their advice. I design piles regularly (for bridges and large structures, not houses) but even with nearly 20 years of experience, I couldn’t teach you foundation design on t’internet. the SE will know how to navigate Building Regs, which I’d suggest is more relevant than your perceptions of ‘sufficient bearing’. My 2c for a ‘feel’ before spending money : dig a slit trench to 2m (your proposed trenchfill limit) then: 1. See how long it takes for water to fill it 2. if it stays (relatively) dry get a sample from the base and try to stick your finger in it. If you can, probably too weak at 2m depth if it floods quickly, that makes trench fill less appealing (H&S warning: dig with excavator if possible and don’t get in the pit. If you have to hand dig, make it wide and step the sides out)

-

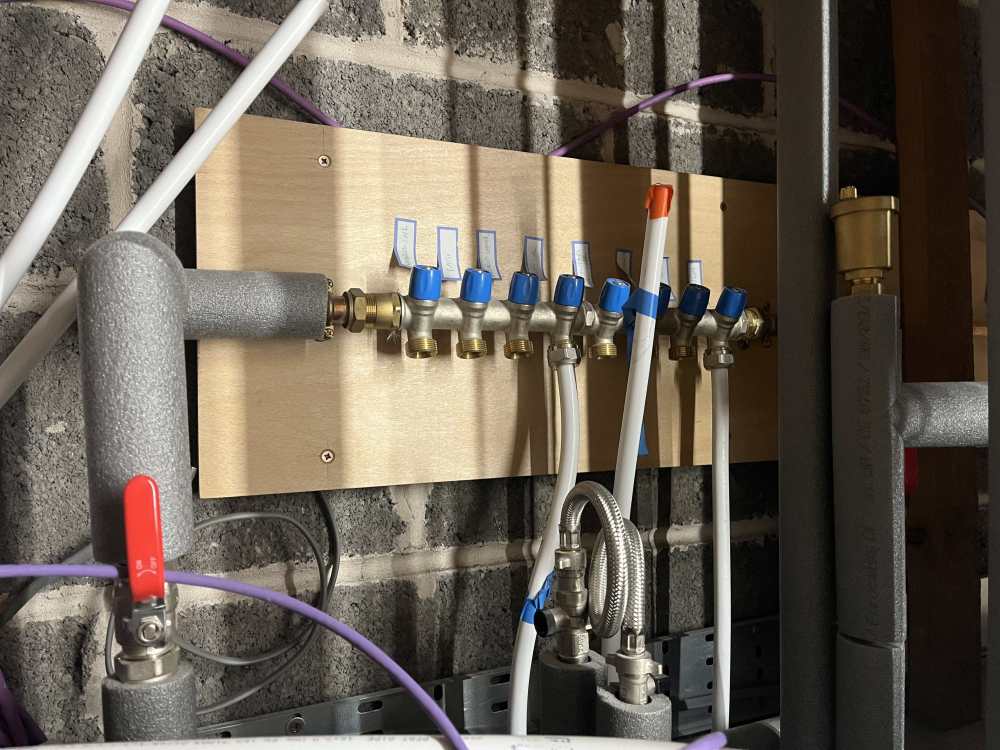

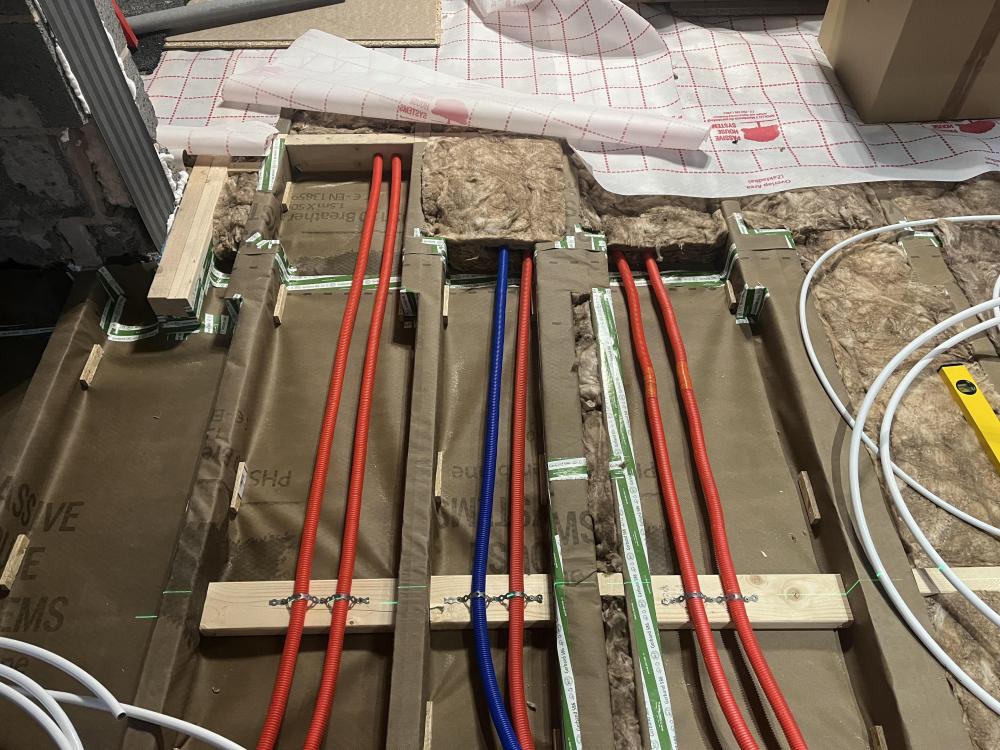

I’ve installed a cold and hot water manifold and am gradually commissioning runs as they are completed. When opening the manifold I get awful water hammer. My guess is that this is air in the line travelling up and escaping through the rubber seal of the manifold tap. (FYI manifolds are located at FF level and so far I’ve been commissioning GF) I had thought about putting a AAV on the manifold (a la UFH systems) but on reflection this probably wouldn’t help air trying to get past the rubber seal. My questions - is this something others with manifolds have experienced? - is it likely to cause damage (E.g if lines needing to be drained and re-filled multiple times)? - is there anything I can do to stop it?

-

See above, don't want to use the appliance spigots on the sink trap. Reason: 1) want to avoid messy hoses in sink cupboard and 2) want to mitigate gurgling noise associated with them

-

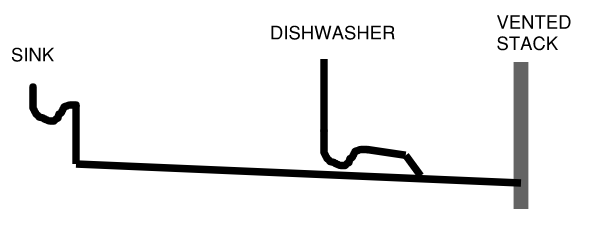

Been wracking my brains on how to pipe this waste. Have a dishwasher between the sink and the stack. I want to use a standpipe for the dishwasher rather than the little appliance spigots. I only ever see the standpipes on the end of a run (probably for a reason). I understand I can't put a trap 'in series' with the sink, as the two will pull on each other. Can I do the below, having the standpipe on a parallel branch, then 'tees' (or more to point, Y and 45deg) into the main branch just before the stack? length of main branch is ~1.5m. The Y would be about 0.5m from the stack

-

I see these ‘reports’ as part of my day job. They are a commercial product designed to collate high level ground risk information, generally speaking to give ‘non-specialists’ an overview (E.g. planners) They are not intended to be, nor should they be, used to directly inform engineering decisions. They require further interpretation normally supported by site specific investigation (either desk study or intrusive) by a geotechnical engineer (or structural engineer with decent knowledge of ground engineering). are those results unusual - no. are they worrying - depends. Im surprised that structural alterations of the existing property seems to have not taken cognisance of existing foundations. BUT you say ‘survey’, which could just be a homebuyer type survey, which definitely wouldn’t look at foundations. Sourcing the design for the conversion/extension sounds important (plans not on planning portal??) Hard to advise on the ground risks without knowing where you are. Compressible deposits covers a broad spectrum! Everything in the ground is compressible given the right conditions. Presence of a stream suggest some alluvial type deposits, maybe on a slope. These do add some risk factors, but not groundbreaking (excuse the pun). p.s. this reply might be too late to be helpful

-

D4 glue.. is this a structural glue? Be careful folks!

OwenF replied to Gus Potter's topic in Timber Frame

Is it worth mentioning that ‘D4 glue’ also seems to be used synonymously with ‘PU D4 glue’ e.g. foaming flooring glue. as above, you can get D4 wood glue from Wickes, but the foaming stuff is not in many high street shops. I’ve found and have used Kronospan (purchased from Howarth Timber in Yorkshire), but at £16 a bottle!! I haven’t used much. (note: this product actually reports to be PVA but can confirm it does foam and fill gaps) did find an online place selling a brand I cant recall for about £5-6 a bottle, but I didn’t need to volume to justify shipping. -

I have 25mm deep battens for a service void, with airtight membrane immediately behind. how is everyone fixing cables in the void? Clipping to the batten feels like cables would be at great risk from a rogue PB screw. I agreed using plasterboard boxes with the electrician, to minimise need for box supports etc. but thinking about it, this means more need for cable support until PB is on.

-

@Mike May I ask where you sourced the Tridonic led modules & drivers? I’ve been through the ‘configurator’ on their website but cannot find anyone stocking the full SLA DC range of modules..

-

There is a view towards ‘de-neutralising’ black I.e. making black = earth and grey = neutral. I don’t think it’s in the regs anywhere but probably one of those things people pick up as though it were.

-

Yea counterbattens isn’t an option due to needing to maintain floor height I’d like to replace all old joists but I think 35week pregnant significant other might kill me I’m liking that two people have suggested shim/packing (albeit different approaches). General wisdom seems to be in favour of sistering over packing, but I’m wondering if plywood shims might be enough to take out the worst (as @Iceverge says) without serious compromise to integrity.

-

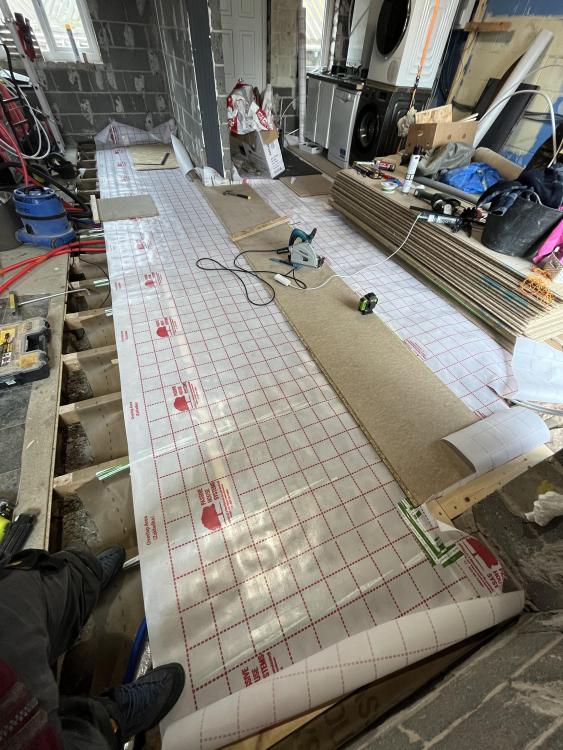

Well…I’ve actually put new joists in half the room, but unfortunately had to work my way across new to old. Everything right of that strip of P5 is new joists. I’ve reached the left-hand extent of the white membrane. Only after moving everything across and ripping last bit of floor (on left out of shot) have I discovered the issue. at this stage, new joists would be undoing a fair bit of work but seems like I’m in for it either way

-

FWIW I was swinging between PIV, PIV&MEV or just MEV. I’m now settled on just MEV (probably centralised - Vent Axia multivent) for wet rooms. Plus a ‘dumb’ extract for hob. I like the idea of humidity controlled trickle inlets but 1) they are difficult to source, especially not in window vent form, 2) my house is not airtight (only partial downstairs with good levels of airtightness) Therefore I’m going to bank on enough background intake and the MEV controlling low-rate/boosted extract based on humidity

-

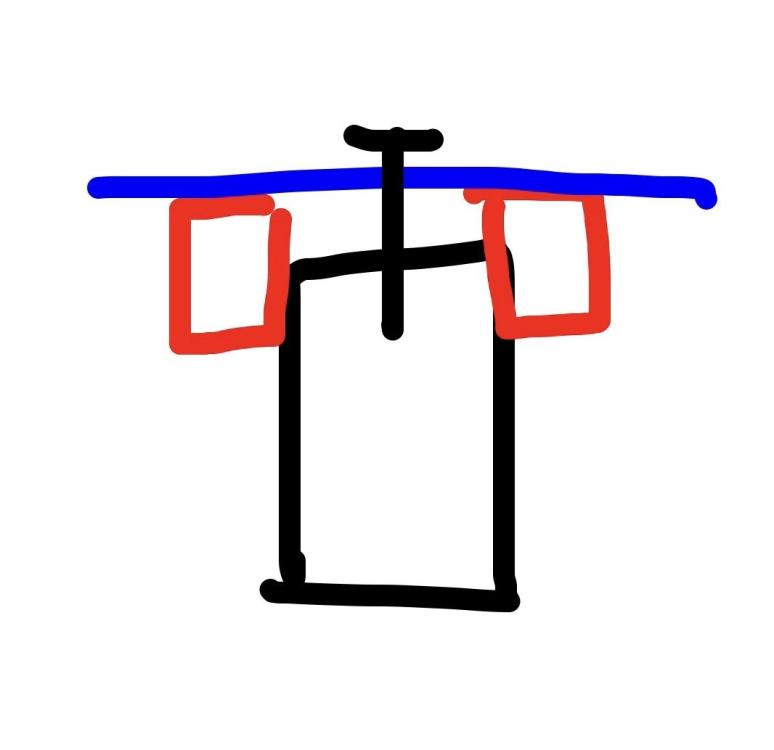

Insulating existing suspended (ground) floor. Have exposed joists and measured approx. 15mm differential across 7m room (parallel to joist direction). Also have ~10mm fall along the joists but TBH they’re up & down where going over dwarf wall/ mid span etc. Decided I will have to sister new timbers to get a level subfloor for tiles. However existing joists are 2x4” at 400 c-c. If I sister with 47x95mm there’s barely any room for insulation/increased thermal bridge. Another option I’m pursuing is to use 25x50mm battens either side of the joist à la sketch below. Plan to fit battens AFTER wrapping joists with breather membrane in ‘up and over’ fashion. AT/VCL places over top prior to 22mm chipboard. I’m convinced this should be capable of taking floor loads provided suitable fixings….but is this doomed to fail?

-

I’ve used this with threaded bar to attach ledger boards. The part fixing the timber to the masonry is just a nut and washer. Do you have that? Surely just un-tighten. hopefully someone hasn’t resin fixed an actual bolt through the timber….

-

I got pipe and fittings from same shop (PSWtradesuppliers) but have no idea if they’re same brand. Fittings appear unbranded. Had to go direct to Multipipe for 12mm to 15mm copper adaptors - only place to stock them. as @joe90 says above, the real benefit of MLCP (or plastic) is minimum or zero intermediate fittings. Mine are uninterrupted lengths of pipe between manifold and rad (or manifold to copper in case of taps)

-

I’m currently using a combination of 12mm and 16mm MLCP in a retrofit scenario. 16mm to cold outlets (from manifold) 16mm for rad flow/return (manifold) 12mm for DHW & DRC so far seems robust and does indeed have little ‘memory’ so holds a shape. HOWEVER I mistakenly thought it would pull through conduit. More than one sharp 90 and no chance. I’ve actually kinked it twice trying to thread a big loop so give yourself lots of working space to ‘lay it’. I’ve spent about £150 in fittings which covers approx: 10x 12mm to 3/4 euro ones 10x 12mm to 15mm copper adaptor 30x(ish) 16mm to 3/4 eurocones 40x(ish) 16mm to 15mm copper adaptor 100m of 16mm and 80m of 12mm cost <£100. A steal compared to JG or Hep. Though despite measuring and thinking I’ll do the whole house with 100m, three rads have eaten the whole reel. can see me using another 200m on top easy!

-

Yes Andrew Millward (whilst a bit persistent with his views) does appear very knowledgable on hydraulic design. The above video explains better than I can but there seems to be plenty empirical evidence that CCTs at the mixer starves UFH of flow. Heat Geek disagrees but does acknowledge a gate valve somewhere nearby (can’t remember exactly where) is necessary to ensure the UFH circuit gets required flow. I converted my previous Viessmann 100 to priority hot water by wiring a 3 port valve in reverse as an external diverter valve. TBF the boiler did have PDHW function (I.e. different flow temps) but only using the internal diverter valve with a 4-pipe setup. I didn’t want to run new pipes so took the LV link for PDHW from the boiler to a relay which gave 240v to power the reversed 3-port valve over to the cylinder only. Have the schematic somewhere but recall linking wires makes the 3-port normally open to heating only. it’s a neat retrofit (not my idea) and sounds like your Baxi might have a similar output for the ‘boost’ mode. You just need something to trigger the relay.

-

1) if you introduce hydraulic separation, you’ll need the UFH/mixer pump in addition to the boiler pump. they might be fighting against each other now, but not once separated. 2) CCTs at the mixer are a no-no. This creates a bypass. CCTs or other separation is done at the boiler look up ‘Heating system design’ group on Facebook. Very good resource for the type of system design you’re looking at.

-

I’m currently installing breather membrane for wool insulated suspended floor. I’m using the ‘up and over’ method (only 150mm gap beneath joists) and I can tell you- THAT is a pain in the arse. Especially around the noggins I’d say if you have access from below, then do it. Will be loads easier. Staple up, tape joins, done

-

Recommend me a ceiling extractor

OwenF replied to Martin-W's topic in Kitchen & Household Appliances

I’m in a similar position My current plan is to have one of these remote (in loft space above the kitchen) venting out via tile vent. https://www.tlc-direct.co.uk/Products/SLTD250SILENT.html Rigid ducted down to a small plenum within some boxing with an egg crate grill eg. https://www.justfans.co.uk/kitchen-extract-grille-with-grease-filter-450-150-cef-p-1454.html Must admit I’m sceptical about the look of it (possibly very industrial) but the Luxair or Elica range coming in around £1000 with limited remote fan options (or at extra £££) is equally unappealing Variation on the above might be buying a cheap, nice looking, hood extractor then gouging the internals and grill out to retrofit a remote fan. -

I extended the 90 up so the ‘nut’ of the 40mm adaptor sits just above structural floor level (chipboard). This will be below a base unit, which won’t get tiled so theoretically I could get to the 110mm opening with a minor floor cut. at worst I can rod direct at the adaptor

-

This. I’ve just done the same for my utility (going to be taking sink, washing machine, condensate and tundish) However, this has got me wondering if the back entry gulley forms an effective trap. The invert of incoming/outgoing is above the reservoir. I guess the little bottle insert must do the ‘trapping’

-

As another data point, my boiler (V100 11kW system on weather compensation) tells me stats for last 7 days. Right now that’s been a period of sub-zero nights with around 5deg avg in the day. Heating: 8.1m3 / day DHW: 1.2m3 / day Quick online calculator tells me for heating that means roughly 90kWh / day = 3.74kW My calculated heatloss using Heat Engineer software was around 9kW. (This includes ongoing insulation upgrades, but I checked existing and rather sadly it wasn’t much different!) I was sceptical of the ACH even for a 1980s build. I suspect this is hugely overestimating losses. What’s scary is that 2/3rds of my downstairs is unheated and drafty at the moment and apparent measured heatloss is 1/3 of calculated before I’ve even completed the insulation upgrades included in the calc! Further data my boiler gives me is %modulation, burner hours and boiler starts. I’ve averaged approx. 100minutes burn time per start over 680hours (including DHW firing), which I understand is not too bad. %modulation has usually been around 10-15% in steady state conditions. (Can be 40% first thing after setback on a cold night) I don’t understand this figure tbh as the 11kW boiler has a minimum modulation of 3.3kW. 10% of 11 is 1.1, so I don’t know what calc it’s doing though with a ‘measured’ heat loss of 3.74kW on an average winter day, I expect my fancy low modulation boiler will still be cycling when it warms up! should have got a heat pump (cry)

-

Must I site my boiler in the same room as the unvented HWC?

OwenF replied to nikbower's topic in Boilers & Hot Water Tanks

Until recently my boiler was several rooms away from the UVC. Now they are within 3ft of each other in my ‘plant loft’ (!) arguably no easier to service (probably harder) but less energy wasted on cylinder reheat as boiler flow only travels 3ft through well insulated pipes. -

UH - Thermostat won't reach set room temperature in colder weather.

OwenF replied to nathan656's topic in Underfloor Heating

A few points: Try a stand-alone thermostat somewhere away from the front door - is that getting close to your target 22.5? Regardless of what the thermostat says, are you comfortable? UFH that has been thrown in tends to have wide pipe spacings. It seems to be a common occurrence that they just cannot produce the watt output to meet the heat loss. Not much can be done about that without ripping out.