The 4 phases from Rainwater to flushing the loo

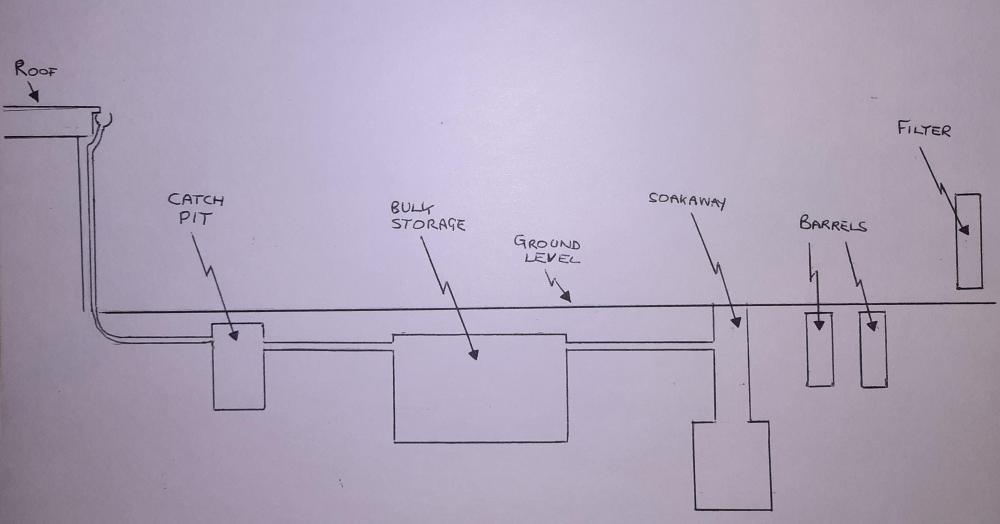

We use 4 phases from rainwater to flushing the loo with it and they are:

- Collecting, separating and storing in bulk tank.

- Fine filtering and storing in barrel.

- filling the gravity tank in the loft

- Filling the cistern

This is not the only system that is possible but one that works with our property limitations.

This design and its controls take into account freezing conditions.

We use two 12V pumps run from batteries and PV.

Here is our system:

We were limited for space and you can use gravity to your advantage

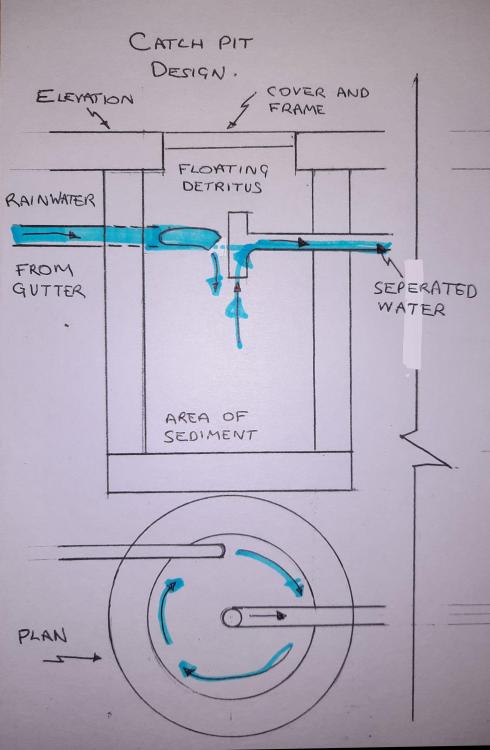

Here is the design of the catch pit:

A circular chamber with a flat base side entry pipes angled to make the inflowing water circulate around the edges.

A Tee set vertically with the branch horizontal.

Construction details could be concrete slab and engineering brick sides with manhole cover and frame like ours.

Needs to either be under the ground or drained before frosts if using a plastic tank.

Ours was 900 internal diameter, really the bigger the more sediment settles, but this is for about 200m2 catchment area. If your going for smaller

I would go for as tall as deep as you can.

The separated water goes directly into your bulk storage ready for further filtering.

Ours has just been cleaned out and I will take photos tomorrow.

M

Edited by Marvin

typo

-

5

5

9 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now