SunAmp - our alternative to a UVC or TS

I just wanted to include a brief post explaining from a self-builder perspective why we have decided not to use an Unvented Cylinder (UVC), Thermal Store (TS) or combi-boiler for our domestic hot water (DHW) in our new build. Instead we are using 2 × SunAmp PV heat batteries heated by E7 tariff. So why?

-

We decided that we don't need gas to be installed avoiding the Gas connection charges, per day supply charge and the maintenance costs on gas appliances. Big saving here.

-

We don't have the room for a TS and we've heard too many horror stories about the problems of heat losses in a passive-house class new-build like ours, so no TS.

-

We didn't want to get into all of the regulatory crap around installing and annual maintenance contracts for an UVC. So strike this one as well.

So what is the alternative?

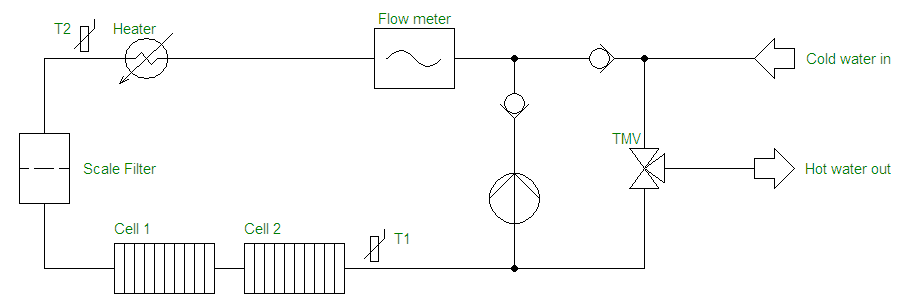

The SunAmp is a thermal battery with an in-built heat exchanger (a bit like a combi boiler) which can store ~5kWh of heat for delivery in water typically at 50-65°C. Here is a simplified schematic of the store. (Note that I've left off all of the essential safety features such as the expansion vessel pressure relief and overflows to simplify this down to the functional essentials.)

The guts of the device are a couple of Phase Change Material (PCM) cells which act as the thermal store. It in essence it works in one of two modes:

- Discharge Heating, where the CW supply flows through the two PCM cells and is heated to between 55-65°C and then blended with a CW mix in a TMV down to a preset output temperature.

- Recharge. When fed with an external electricity supply (typically PV or E7 off-peak tariff power), water is circulated internally through the cells and a 2.8kW heater to bring them up to an internally preset maximum temperature.

So the SunAmps can only be charged by electricity, and there is no alternative form of heat supply. The form-factor is very small – two SunAmps side-by-side take up (d × w × h) 530 × 600 × 740 mm. The rectangular packaging also facilitates the use of internal vacuum pack insulation panels so the total standing heat loss is ~ 1kWh / day which is a lot less than a typical TS.

The exact choice of PCM is specific to SunAmp, but the linked Wikipedia article lists the common ones with a phase change at around this 55-65°C range. However in terms of the physics of how this all works, it is easier to describe another common PCM that we are all familiar with and which has its phase change at 0°C: water. There are three material properties that you need to consider when looking at how a PCM works: the specific heats of the solid and liquid phases, that is how much heat you need to supply to heat 1 kg of water by 1°C and the latent heat of fusion that is how much you need to convert 1 kg of water at 0°C to ice at 0°C. I could give you the figures but a good way to think about is that you need the same amount of heat:

-

To heat ice at -158°C to ice at 0°C

-

To melt ice at 0°C to water at 0°C

-

To heat water at 0°C to water at 80°C.

OK these ratios and the fusion temperature differ for different PCMs (as well other properties which reflect the long term stability of the using it in cells, etc.), but that is all the proprietary stuff (discussed in the detailed below from Andrew Bissell). Even so, the bottom line is simple: the systemic heat losses are far less than alternative solutions, and

Weight-for weight you can store roughly four times as much heat in a SunAmp PV store as a conventional DHW cylinder.

As to why we have chosen the 2 × SunAmp PV approach, there were 2 main drivers for us:

-

5kWh isn't enough to meet our typical daily use, and 10kWh is so we will be able to charge our stores overnight at E7 rate and only need daytime top-up in exceptional circumstances.

-

The pressure drop across the store in Bar is roughly 0.0142×f1.81 where f is the flow rate in ltr/min, and if you crank the numbers one store doesn't give us enough flow rate.

Even so if we look at our planned use (I'll go into the figures in a later blog post), our household of 3 people has had an average use of 280 ltr/day averaged over the last 6 years. Most of this is hot water -- say 80% or at an average lift of 25°C, this amounts to 5,500kgK = 6.4kWh/day or 7.4 kWh/day allowing for heat loses. This will cost us £194 p.a. at my current electricity tariff for my household's DHW.

Will I really realise the payback from additionally investing in gas or ASHP based DHW systems? I think not.

PS. Slightly amended wording to reflect the earlier comment of Andrew Bissell quoted below.

-

2

2

21 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now