Insulation Panels

It has been a cold week, so just after 12:30 on the 15th of January 2024, I started a small, but limited, experiment.

This was rather prompted by a comment by @Garald who wanted to insulate at the back of his book shelves, and mentioned our favourite insulation, multifoil. @Gus Potter also has a project that may benefit a thin, easy and cheap to make, insulating panel. I think I also made a comment to @saveasteading about this experiment, but can't remember in what context.

Now I have always been dubious of reflective type insulation. Works great at high temperature, especially in a vacuum, it is how the cameras on the James Webb Telescope are kept cool.

But we are not Billionaires, so I used hardboard, pine, white emulsion paint, double sided tape, small screws, clingfilm and aluminium foil.

Basically I made some small St. Ives picture frames, put them face to face, separating the 24mm air gap with clingfilm in one, and aluminium foil in the other. The total thickness of the test panels is 30mm.

Each side of the test material had temperature sensors (DS18B20s) inserted via holes in the frame. These had been calibrated before hand and the analysis is based on the calibrated data.

Other sensors where fitted in the room and externally to log ambient temperatures (why being a cold week was so good).

The panels were then stuck to my kitchen window with double sided tape.

The position of the sensors allows for a combination of temperature differences to be logged, logging was at the minute interval but the analysis was based on 6 minute means.

A quick calculation to check the standard error showed that accuracy was a factor of at least 10 below the 0.1°C accuracy of the experiment.

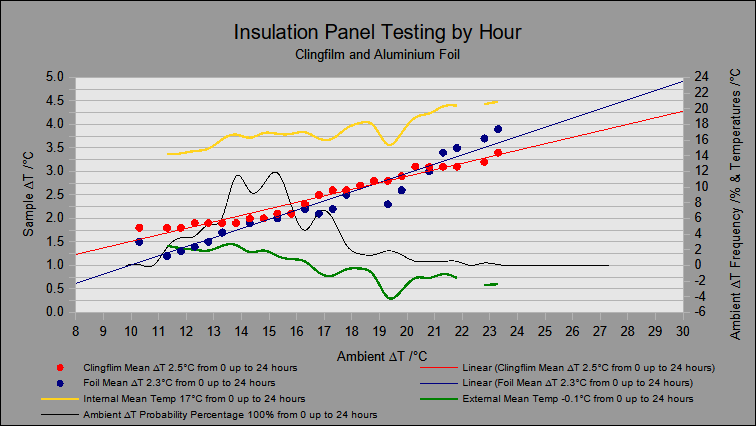

The data analysis was based around temperature differences, but for some context, internal and external air temperature is also shown on the charts (right y-axis). A frequency distribution line was also added, this is black line (right y-axis) and is called Ambient ∆T Probability Percentage. The Ambient ∆T is the difference between the inside temperature and outside temperature. This is also used for the 0.1°C temperature bins that create the x-axis.

Mean temperature differences between each side of the clingfilm or foil (shiny side towards warmer room) were also calculated and binned according to when they happened with respect to the Ambient ∆T.

This method is used as it is more relevant than a time series that can fluctuate during the day, it is the properties of the insulation that is being tested, not the absolute 'comfort' levels.

The below chart shows the total test period results. Test period (15/01/2024 12:26 to 19/01/2024 12:42)

Always remember that these are temperature differences and not absolute temperatures, except the Internal and External mean temperatures (yellow and green lines) and the probabilities (black line). Those 3 are read from the right hand axis.

The Clingfilm is the red dots and the Aluminium Foil is the blue dots. Linear trend lines have been added more for clarity than actual predictions.

A can be clearly seen, there is not much difference between the two datasets. The Clingfilm performs better overall with a mean difference of 2.5°C, to the Aluminium Foil's 2.3°C.

Above an Ambient ∆T of 19°C the Aluminium foil performed a little better. This is actually saying, the colder it is outside, the Aluminium Foil performed better, which may be important comfort, but overall, there will be greater energy losses than with just using Clingfilm as a separator.

It is, purely from a climate change viewpoint, the overall energy reduction that is important. Climate change has caused the mean temperature at my end of Cornwall to average -0.1°C for 4 days. I have lived back here for 20 years and never known such a prolonged cold period.

I am now running a second test, using one panel without any separator at all, and the other one fully filled with silica micro balloons. Micro balloons may sound exotic, but they are just filler used in the plastics industry. I don't think the temperature differences are going to be so great next week, which is a shame as the greater the range that can be tested, the better. I can always raise the temperature in the room to compensate, but as I raised it up to 24.5°C a few times, which resulted in only getting a mean of 23.5°C in the room, it will be a bit costly and not very environmental.

I shall post up the results of the second test next week, all going well.

Edited by SteamyTea

-

2

2

-

1

1

16 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now