Search the Community

Showing results for tags 'occumster'.

-

Wow, we have finally started, and what a journey. The goal of the last 8 days was to try to make the the stars align. We had planned several meetings / connections deliveries all to happen the 1st week in April, and this was it, lets see what unfolds. Firstly, the plot, being located high up on the East coast in the highlands, which is basically a large un-serviced field has a few logistical issues, the main one being storage, the second distance. We had quotes for containers to be purchased and delivered in the region of 4.5K so alternatives were needed. The initial solution is the back of an Asda delivery waggon, 12ft long, 7ft wide,6ft high, with 3 lockable doors, and racking for the green trays, also a larger roller shutter section. £250 - with working fridge if required - (this may have a second life once were up and running with rare breed pigs🙈). just need to get it from Morecambe 430miles North. Secondly how to get everything to site. We bought an old removals wagon - 7.5Tonne ally box with tail lift. MOT till NOV 515,000KM - 1 careful owner Our hope was for this to get there in 1 piece, and be left on site as storage. the sum of £1200. all in with insurance (which may be cancelled) its has cost us £2K. Talking with my timber supplier, he warned me of impending price rises and possibility of shortages due to the unrest in the UKRAINE. so out of the blue I bought all the timber 450M of 6x2 C24, and 56 off 11mm OSB for the PODS. In addition to this I found a contact selling factory rejects of 120mm PIR insulation. In Scotland the pods need to achieve good U values, so 120mm on roof and in floors was required. Basically this guy buys pallets of insulation that are usually end of production run , or slightly damaged corners etc, and not full sheet sizes. I went to look, as he has had some bitumen coated and fibreglass coated boards. Generally the sheets are all 1200mm wide, min 600 long, most are around half board length, but will need to be trimmed to make them suitable for the warm roof. I did a deal to buy the equivalent of 44 Boards of 120mm some Bitumen coated, some fibreglass for the sum total of £660. This is a massive saving on 'Box Fresh' Now I had a problem, with the insulation tightly packed into the back of the truck and leaving some pockets to slide the timber in I had filled about 2/3rd of the truck, I didn't have room for all the timber or the other stuff I was taking. The revised plan was to cross our fingers and hope the truck will not only get to Scotland , but now return with a view of making another trip. Living accommodation. We found a static caravan, 2 bedroom in V good condition, delivered to site included in the price. The deal was done and he would get the van to site for our arrival on the Thursday, along with the delivery of our other investment an old Ford 550 Backhoe Loader, with buckets and pallet forks. We decided to set off Wednesday evening, with the plan to see where we got before we were too tired, then to sleep in the Wagon / Car. The picture below was us all loaded with 430Miles ahead. Me driving 'Nessie' as Mandy has called her, and Mandy Driving the Car / and trailer. I know we look like 'Travellers' but needs must, what will the new neighbours think when we turn up..... The Journey was horrendous. Setting off at 18.00 the trip was uneventful, with he exception of filling Nessie to the tune of £245 with diesel and not knowing how far these 150 litres will get us. Uneventful until we got to the A9 around Perth, then the snow started. Visibility was poor, and the local truckers seemed oblivious to it. Mandy had a big scare on a dual carriage way where she lost visibility of the edge of the road, and found herself nearly hitting the verge, a stab of the brakes and forgetting about the 16ft trailer saw said trailer try to over take her. Luckily she managed to correct this, and coming to a stop in the dark with snow on the dual carriageway, composed herself and set off again. At 03.30 on Thursday we pulled into a layby just after Inverness. Got our heads down for a couple of extremely cold hours (-4). and set off to the croft, arriving around 8.30.. During the drive we were informed the Static- our accommodation for the week was not going to make it - COVID... I managed to make a few calls and Borrowed a 3 berth Tourer from GOW Plant Hire / Groundworks in Caithness.. What a top bloke.... This is us on site day 1, digger arrived..... The Plot.. So down to it. Day 2 on site Friday. Electricity was to be connected on Wednesday 6th, we needed to dig a 30M Trench and install the cabinet / concrete base. This had to happen. Over to the digger to fire her up.... no go. Quickly the battery went flat. We moved Nessie closer, did a quick 30Mile round trip and bought some jump leads and by lunchtime and still no joy, turning over but not firing..... it was running the day before but they had to jump start as it had been sat in the yard for a few week. Ok looking at the battery it wasn't the correct one, so another 30mile round trip and the owner of a monster battery we tried again. no luck, I phoned a mate mechanic he advised trying spraying cold start into the air intake. ok another trip? , No, he told me to try deodorant as the propellant may well work, one quick spray and the old girl fired immediately. Best smelling digger in the highlands... Now to get to grip with an old backhoe, I've experience with up to 5 tonne 360 machines but never a back hoe, so this took a while to understand how to dig a straight trench next to a fence.. I managed to excavate the connection pit and around 15M of wandering trench by the end of the day. Day 3 Saturday It was cold and no amount of deodorant was working on the digger. The mighty battery was losing power... Time to try Nessie to give a boost, we got the Truck stuck in the mud... FFS. we needed the digger to move the truck, and the truck to help start the digger... This was a testing day, and I know from experience in building game you have days that just fight back, and this day was fighting hard. Mandy set off in search of some supplies and some cold start. By lunch she was back, I had made the shuttering for the cabinet base just needed the digger to get the concrete over to the hole. Cold start didn't work and we both felt deflated... Numerous attempts with planks, stone etc to free the truck were not working. As a last resort as the sun was now out and shining we gave the cold start another go and the digger jumped into life.. Obviously not a morning person... We moved the truck to relative safety of some drier ground with the aid of the digger and concreted in the cabinet. Another 10 M of trench, and we made a start exposing the water main. I noticed the digger was beginning to be sluggish and leaving hydraulic oil pools, when I check the level it was nearly empty. So Parked up the digger, next to the truck, batteries next to each other - just in case. We retired to the un heated caravan, and I went to the Generator to start it, we had a 2KW heater that helped take the chill off, A couple of pulls and the cord snapped😂. the day was going to round 12 like it or not. So tools out and repair underway. Day 4 Sunday. No Hydraulic oil till Monday so left the digger alone, and marked out the position of the pods, and the septic tank, I wanted to do some digging here to confirm the suspicion that the rock level was high, and some breaking out will be required. We hand dug a trial hole for the water main, as we found electricity cables running towards where the trench was going. We hit rock 300mm below ground, so were happy to dig this with the machine on Monday, We also started unloading the insulation and timber from the truck. We sandwiched timber and insulation with visqueen and ratchet straps to create a heavy mass that hopefully wont blow away whist were not there. Day 5 Monday. With Hydraulic oil on board and the shelter of the truck the digger fired first thing, and we were off. Mandy continued un loading insulation. We dug a small trench for the water (we new the main was laid in a blasted trench to a depth of 800mm) we had to breakout our trench with a 110V Breaker to obtain the 600mm depth and hand dig to expose the water main, I left Mandy to this while I dug the septic tank hole, I got to a depth of around 800mm before I hit the rock. This will need pecking out now. We installed a homemade standpipe, and blue pipe, then asked for a track inspection via the online portal. We were given date of 11/12/13April, but we put a note on to say we were on site until the 8th. They responded and the Meeting was set for Wednesday 6th - result. Day 6 Tuesday - the night was very windy and wet. A cold and wet start, We finished off the electrical trench, laid the ducting / draw cord and all was set for connection the next day. Made a start on the pods foundation dig. Day 7 Wednesday - electrical trench was full of water, and the ducting was floating. the heavy rain drains towards the sea, and thus straight into this trench, I was concerned that the Install may be called off. SSE turned up around 10.00 and were not bothered in the slightest. They connected a new length of 95mm Wavecon to the pole and jointed the existing 2 houses and our new supply - 2 core 35mm straight concentric to this 95mm cable. Resin pour joint box, and fitted the 100A cut out in the cabinet. They were done in 2 hours. left me to throw the cable in when the resin had gone off. Scottish water inspected the trench, and this has been signed off and will be added to the works list, hopefully a few weeks. I filled in the cable trench, We managed to rough dig out the pod foundations and found the rock is close to the surface. so the slab foundation will be pretty much mass fill concrete around the perimeter, with some MOT to reduce the thickness to 4" for the slab. This will then have a Radon barrier on top and a floating floor insulation on that, Due to the poor living conditions and more rain and wind we made the decision to leave Thursday morning. Day 8 Thursday, We packed up the caravan and Nessie then dragged the caravan out of the mud with the digger. The trailer was also dragged clear with the digger, but Nessie was so at home she didn't want to leave. I was pushing here through the mud, but she was sinking. Fortunately tour Farmer neighbour saw our plight and came along with his massive tractor and dragged her clear. We left site battered, bruised but happy in the knowledge that no matter what was thrown at us, we had achieved what was required and more to boot. Thanks for reading... its all possible, Mandy made a few videos if you want to see them https://www.facebook.com/The-Windy-Roost-101816829105927, you can follow the progress there as well...

- 10 comments

-

- 8

-

-

To finish my 22 days on site. I started timber framing, decided to start on the amenity block, as this will initially be for our washing machine and dryer, plus some storage. My aim was to get water tight -ish. before I had to get home for the weekend. The poly tunnel (constructed this visit) - is my cutting shed, I set up my chop saw and worked to my cut list. This was proof of concept on my build plans, and it needed tweaking, the roof to wall junction has been modified and will work, but I want a better / neater solution for the cabins. here's my first attempt with the Binno camera. amenity.mp4 The wind picked up (20mph with 35mph gusts, so I needed to get some structure and racking boards in place, so the camera set up didn't happen day 2. I left site with it wrapped, and with the vapor barrier on the OSB roof. (with some 6x2 to reduce the wind uplift. I'll need BC to have a look before I put the insulation on the roof, as I want the insulations and rubber to go on on the same day. This block and the cabins will be clad in Scottish Larch. There's a gap above the door, that needs the final framing to be finished, but generally happy with the result. so far.

-

the windy roost Cabin Foundations and the Amenity block.

Jenki posted a blog entry in The Windy Roost

My dual roles for the first 10 days of the June / July trip was to get ready for concreting. This breaks down into two slab / raft foundations for the Cabins, 1 slab for the amenity block, and some backfilling of the treatment plant, and while I'm at it, concrete for the Polycarbonate Polly tunnel. another blog to follow. In my opinion, the structural calculations for the slab rafts were well over engineered. the slabs will be ground bearing (rock) foundation and thinner slab, all poured at the same time. The Radon barrier and timber frame will sit on this, with an insulated floating chipboard floor. I know this will give some thermal bridge on the timber frame, but these are camping cabins not the house. Costs said this was the way forward. I'd already exposed the rock for the cabins, so BC could see this, and was happy for me to crack on. I framed the the cabins with 6x2 timber, and levelled this formwork. Then used crush and run to raise the central slab area up, to leave me a 100mm thick slab with thickened foundation perimeter. This perimeter varied due to the level of the rock. I used around 6 ton of MOT in each cabin., then A252 around the base of the foundation and A142 across the slab. At the corners of each slab I ran the WC waste, and also a feed for H&C water, power and internet supplied for the amenity block. The amenity block was a simple 150mm Slab on compacted hardcore. With this prep done, my wife, (the now only breadwinner for the next 8 weeks), was due on site, for a baptism of fire..... To be fair Saturday and Sunday consisted of me and Mandy getting the mesh in place and getting the post support for the extended roof of the cabins dug, tying the mesh, getting the post support brackets ready. and some land clearing/ hole digging for the Poly tunnel. Monday is concrete day..... The plan was simple. the truck would reverse up to each cabin, drop around 5 Cube in the cabin, whilst I'm levelling, then the remainder would go into the amenity block. we would float this, and then when the truck came back pour the second cabin, finish the amenity block, and whilst waiting for the truck to come back get this floated off. the last load would be the treatment plant (this would be using the loader bucket) and leave a little for the poly tunnel.. easy 15cube, no problem.. It didn't work this way, Mandy, who is game for anything, but being an engineer needs to know what she is doing. She has never laid a slab.. didn't matter, because I was going to do it, no problem. she was there as a go for, and edge trowel-er (I must point out, I knew that the surface finish wasn't important, as its being covered with insulation and membrane - but) The wagon turned up around 10, after a 30 min trip to site, the day was damp, with slight rain, not overly hot, the driver would not drive on to the earth next to the cabins. So I had to use the loader. (an old Ford 550) the first half bucket was solid, I could tell by the colour, there was a lot of cement in the mix, I told him to add water, lots of water, but he didn't have "loads" so the best we got as a stiff slump, I loaded as fast as I could, and Mandy was trying her best to rake / shovel this level, and she was doing a great job, but she didn't know what she was doing, and it was hard work. I thought the concrete was wetter than it was. after about and hour we had the concrete out and some in the amenity block, but it was far from level, and starting to go off. I had to use the loader to level some more, than then used my beams to get it flat. This was hard, and the bull float wasn't bringing up a lot of cream..... I asked for a wetter mix for the second drop and asked for 2 hours to get set. I got the slab flat and fairly good, but not great. Whilst Mandy was teaching herself to drive the digger, (she wasn't having round 2 with the rake). Round two was worse, the mix although a little wetter, was setting faster. Mandy put the first few loads into the amenity block and I levelled this, then started on cabin 2, it was a real graft. Again the loader was used to move the setting concrete, there was some concrete left, so this went into the treatment plant pit. With the running around the site, cabin 2 slab was far from finished and I had to resort to putting water on top to help. Not my best day. I get the slab level., but floating was not producing a smooth mirror like finish. We also had to set in the post support into the 4 shuttered blocks. and had around 3/4 of a bucket left in the loader. We rounded the day off with setting the posts in the poly tunnel. We got cleaned up around 18.00. The amenity block and 2 cabins were flat and floated, but not fantastic (hence no photos). the treatment plant had around 1 cube of concrete and the 14 posts were set. 13Cube of concrete, and Mandy politely informed me, she was never concreting again.... Tuesday, we needed to finish off the treatment plant. but couldn't get concrete until late afternoon. The morning we started on the poly tunnel, but decided that we needed more concrete, so created a shutter to link all the posts with a plinth. The 3rd Batch of concrete was the worse, we did about 9 loads with the bucket and it was setting again. we left a full bucket for the poly tunnel, levelled the concrete around the treatment plant. (the driver informed me, that I probably had got more than 2 cube, as there was some in the mixer when he loaded mine, so that explains it going off real quick then. Anyway. we persevered, were still married and talking to each other, and we achieved the goals..... The future house slab pour will need more people, a different concrete company, and a solution that doesn't need my digger, PUMPS are not common this far north, thinking cap on. thanks for reading. -

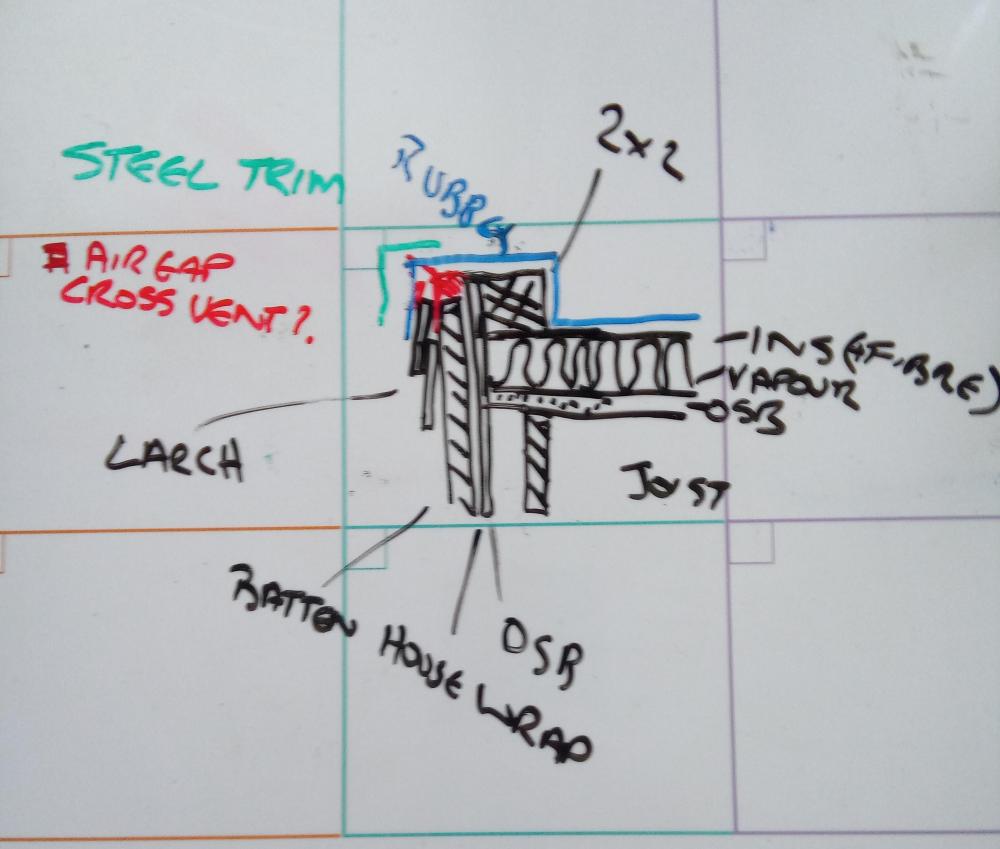

I'm after some thoughts on my cabin roof / wall junction. I want a clean line i.e. not a roof overhang with facia and soffit. Question is would a gap at the top be sufficient for air to flow and allow the wall to breathe. This way I can rid myself of the Need for expensive trim and keep the look clean. Build. 6" stud with warm roof. Clad in larch. Rubber roof on 120 fibre coat insulation.

-

- the windy roost

- highlands

-

(and 2 more)

Tagged with:

-

Its obvious I will need to improve the heating in our static. ( As well as the drafts). This fire can be on for an hour and you wouldn't know. I've been offered a 6kw (wood burning stove) for free, that will fit, but thought I'd seek the advice of those who've trod this path previously. Background: We don't have any wood lying around except the offcuts from framing. The 2kw heater does get the place warm. My plan is to remove the fireplace and wooden sides, install a base probably some form of paving. A heat shield at the back. The stove flue will be a short iron adaptor and then twin wall as soon as I can. Existing through the enlarged existing hole on the roof I've got a cheap thermometer so can check the surrounding temps. Is 6kw too large, I know I don't need to fill it to the brim but? Any suggestions for a cheap but acceptable heat shield. Any other suggestions before I take the plunge. It's been lovely up here the last few weeks but the caravan still drops to 15deg overnight. Winter will be long and hard if I don't sort this. Also any tips on improving the drafts on the single glazed windows? Thanks in advance.

- 14 replies

-

- the windy roost

- occumster

-

(and 1 more)

Tagged with:

-

The next stage of the setup of the site took place over the last 3 weeks. with some good progress. The trip up North, 433mile from our current rental in the NW of England. I set off on Wednesday morning in the 7.5T truck, and the 2 dogs for company. I took some materials with me, and had a gut feeling I was overloaded. I had worked out the approx. weight of what I was taking, but was unsure of the TARE weight of the truck. so I didn't take all I was planning. Luckily the nice guys from VOSA, At Carlisle (Todhills check site), confirmed my suspicions when the invited me in for a check. I was over weight, but the truck and my paperwork were all in good order, and they give the truck a thorough looking at. The upshot of this was me renting another 7.5T truck for storage, offloading the excess weight, driving the remaining 333 miles, unloading, returning the next day with the empty truck, re loading and driving back to site. 1100 miles in 38 hours. not what was planned, but you live and learn.... I arrived back on site on early Friday morning, 02.30am. and slept in the cab of the truck, until I was woke up at 05.10, by the guy delivering the Static, he was at the end of the road... Here's a screen grab of our new home arriving to site, this was 05.25 am... I hired a contractor to carry out the highway works for the site entrance, basically as he had the correct insurance and RAMS it was easier to get this stage subbed out. The idea was he would open up the site, with a 5 T digger, start the initial road and stone this up with around 60T of type 1. I would then meet on site and hire his man for a few days to assist with the pecking of the treatment plant. This didn't go to plan, they had to use a 13T machine, as it was available, so when I eventually get to site on the Thursday, due to the size of machine, the operator has completed the initial works, then pulled out approx. 60M of the road, and pecked the treatment plant hole, and I got this for free... 😁 Having a 13t machine on site, with operator for the Friday, I needed to make the most of it, as I was only paying for the rental of a 5T machine. Mikey the operator, made short work of pulling out the remainder of the road up to the location of the house, in total this road is around 90M. Next I had him strip the area for the house. The house is around 13M x 7M, so I wanted to strip back a working area around the house, my thought was we would hit the bed rock so this was the plan, we marked out a 16M x 11M rectangle, and he set to it, it took him about 2 hours to strip the land and scrape it clean. The above is the bedrock where the house will be, and the road coming up the side of the house. (I used a geotextile as a separation layer for the road, although in sections the road is on bedrock anyway,) You can make out that there is a fall from the top left falling to bottom right, this will be made up with type 1 stone, raising SW corner of the house around 700mm, I will raise the road in this section and use some of the top soil to level this out a bit and soften the impact. The last Job for Mikey was to dig me the trench for the services, he dug a 600mm wide trench about 8M short of the Treatment plant (to allow me access to move the spoil, and a similar distance short at the other end for me to connect to the water. just shy of 60M. Friday was a busy day on 3 hrs sleep. The treatment plant also arrived as can be seen above, I went for a Tricel unit, this was based on cost, treatment, dimensions and availability. Last job for the day was to move the caravan, Mikey helped me with this and we stripped a bit more land and located here temporarily for the night North / South. Saturday I decided to get the water connected to the caravan, for this I needed to complete the trench from the standpipe to the large service trench. I never dug this on the first trip as I was concerned about the electrical supply to my neighbours property. Cables seemed to run across my field at around 300/ 400 mm depth. I used my contact at SSE and he arrange to get the cable moved / deepened. This was carried out a few weeks prior and we discussed the position of the new road, and he made a site visit and we talked about me extending the water pipe trench in both directions so that I could also lay a utilities duct to the road for broadband. So to say I was a bit surprised, and p***ed off when I cut through the neighbours supply cable. The cable was as I was worried about 400mm deep, and the marker tape was next to the cable.... How to upset your new neighbours by having their electricity supply stopped two times (1 for the initial connection, 1 for the remedial works), only for me to cut the cable for a third time.... At least they were very prompt, they arrived after about 40mins, and it took him around an hour to re-joint the cable. I then removed the water standpipe and ran my new water main up to the caravan. It will tee off for the pods at some point, and then continue up to the house. SO now I had running water in the van, and gas for the water heater and hob / oven. Sunday was glorious, so I caught up on my sleep, and had a restful day. Scottish Power were due to fit the meter on the Wednesday, so I needed to get my service cables from the meter box into the service trench and up to the caravan and to the pods. I dug a trench across the road and through to the service trench. I used a 125mm Duct, and inside here I ran some 6mm SWA to supply the pods and some 50mm Duct to run a service cable to the caravan and ultimately up to the house. I pulled the cables through, and I have put a caravan hook up point next to the static. Tuesday / Wednesday, I had 80T of Type 1 MOT delivered in stages, I spread this out using the Back hoe, and vibrating roller. so by the end of Wednesday I have the base in for the road. which will give me good access for deliveries. Scottish power were a no show..... Discussing the caravan with the neighbour they advised turning the caravan 90deg, so it was end on East / West as the stronger winter winds tend to blow from the West, and being side on would ultimately be unstable. I dug out another section of land next to the caravan with the idea of swinging the van around at weekend when Mandy Joined me for the last week. It took me and Mandy all Saturday to move the van, using the backhoe to pull it around. and most of Sunday to get it jacked up off the ground and levelled. We dug 4 pits later on in the week and concreted some anchors in to chain the van down. The van in position with Mandy getting the best job of the week to squeeze under the van and start to insulate the water pipes... Scottish Power let us down again with a missed appointment on the Tuesday with a promise of Friday.... They actually turned up late Thursday and fitted the meter, so we had power on the Thursday night. We spent a couple of days moving spoil around the site to create a mound of earth to shelter and soften the impact of the pods, this was also a planning requirement for the neighbours amenity. Still work in progress and there's 10's of tonnes more to move. Last job before packing up on the Friday was to level the base of the treatment tank pit. At this point we were still waiting for the building warrant. so couldn't actually install the plant. We end the week by getting the Building warrant approved, and the certificate for discharge for the treatment plant both on Friday. Thanks for reading..

- 3 comments

-

- 8

-

-

- the windy roost

- occumster

-

(and 2 more)

Tagged with: