Search the Community

Showing results for tags 'lintels'.

-

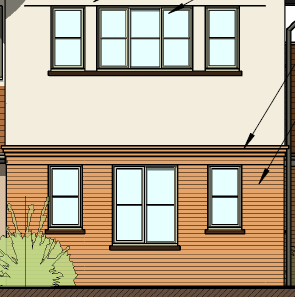

Hi All, Our builder called round yesterday to say he'd had a cancellation and could start our small, single-storey extension next week (about 6-8 weeks sooner than we had planned) if we wanted him to do so. Given how difficult it is to get a decent builder to even quote for a job at the moment I rather hastily said it would be fine. Now, as I realise how unprepared I am I'm starting to worry a little. I like to be fully prepared for something like this and that includes understanding the methods and materials that they'll be using. It will be at least a week after they start until they actually start building (there's an existing structure to remove, drains to lay, water main to re-route and foundations to dig and pour) so I have a little breathing room. The extension will be 3.2m x 1.6m and sit in the L of two existing solid stone walls (one of which is rendered) so we're effectively building just the two new walls. We are knocking the exisitng outer wall through to make a larger kitchen, that wall is 400mm thick stone. I asked about what type of structure they would use when knocking through and they said proabably Catnic lintels supported in the wall on one side and on vertical steel posts at the other. Having looked at Catnic lintels I'm not sure whether they are the best choice for stone walls? I'd also be grateful for your opinions on construction methods for the walls. The builder proposed three different methods: double skin wall of concrete blocks with insulation between, single skin block with timber frame inside and insulation in the framing, timber framed with either timber cladding or a stone veneer. I imagine that each method has it benefits and drawbacks but as of today which do you think would offer the best combination of thermal efficiency, acoustic insulation and value for money (based on both material and labour costs). Is there an alternative construction method that I should be aware of that isn't overly complex, expensive and suits the scale of this project? As far as looks are concerned there is exposed stone to one side of the extension and rendered stone to the other so either stone or render will be cohesive, I suspect that timber may look slightly at odds being a third material type. I feel like my back is to the wall somewhat but I don't want to pass up the opportunity to have the work done if it means I have to wait another 6 months to get them back again. My builder and agreed to take the weekend to consider the project and discuss it again on Tuesday. By then I'd like to have a clear idea of my best options so I don't get strong-armed into something I'm not entirely happy with. As ever, all thoughts, contributions and opinions are greatly valued.

-

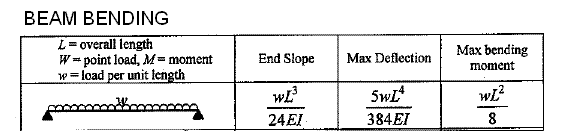

For long spans the loading can rise considerably. Not only does the load rise in proportion to length, the resulting peak moment on the resisting member rises with the square of length: The section of the member needs to get increasingly large to resist the increased moment and still the designers typically allow a deflection in proportion to length. As I understand it, this is typically L/325. That means that a lintel for a 3300mm opening will allow a 10mm deflection at the limit. Cavity lintels for large spans (e.g. >2400mm) start to become very expensive if there are roof or floor loads near by. For example, a 3750mm lintel with a total UDL capacity of 50kN runs to around £200-£400. Steel beams have huge moment resisting capability depending on their section. There is a range of Universal Beams (aka RSJ) which have a width of 102mm well suited to a 100mm internal leaf. A 3800mm 305x102x25kg beam costs around £200. I want to understand when to swap to such a steel. Considering just universal beams for a 3400mm opening with 50kN UDL: Section Iy(cm4) Deflection Saving 178x102x19kg 1356 L/364 (9.3mm) 22% 203x102x23kg 2105 L/564 (6.0mm) 6% 305x102x25kg 4455 L/1200 (2.8mm) 0% NOTE: 254x102 UB omitted A cavity lintel would probably have a deflection of 10.5mm (L/325). Steel beam advantages: reduced deflection, greater capacity, lower cost Steel beam disadvantage: rarely galvanised and so needs careful painting etc when exposed to cavity, needs boxing in for fire protection Cavity Lintel advantages: galvanised, makes provision for outer leaf, stated capacity so no need for Structural Engineer's input Ease of installation can go both ways. At length, both are heavy. What experience do people have and when do they typically change from cavity lintels to steel beams?

- 15 replies

-

- rsj

- universal beam

-

(and 1 more)

Tagged with:

-

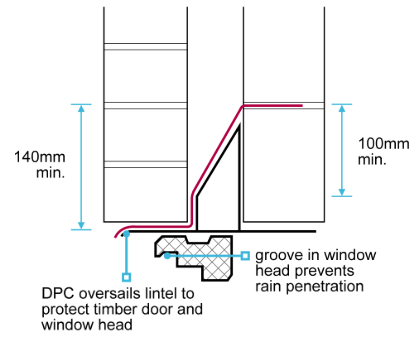

This may be daft question, but how do you conceal the outer part of a window or door lintel in brickwork. The brickwork above the lintel is sat on top of the lintel and I don't want to be able to see the metal underside of the lintel when finished. What are my options? I know you can get special soldier course lintels but we don't want a soldier course. Feels easier to hide it in walls that are rendered, but bare brickwork walls feel harder to hide the lintels in. Do people just paint the lintel? More RAL charts with the wife if so which isn't my favourite activity.

-

The NHBC guidance documents show the outer edge of the cavity tray DPC going past the edge of the lintel (see below). I've not noticed this done and have seen it trimmed back from the edge, for example this video. What did people do themselves here? I'm not sure which presents the greater risk of capillary action drawing water into the cavity under the DPC of the cavity tray?

-

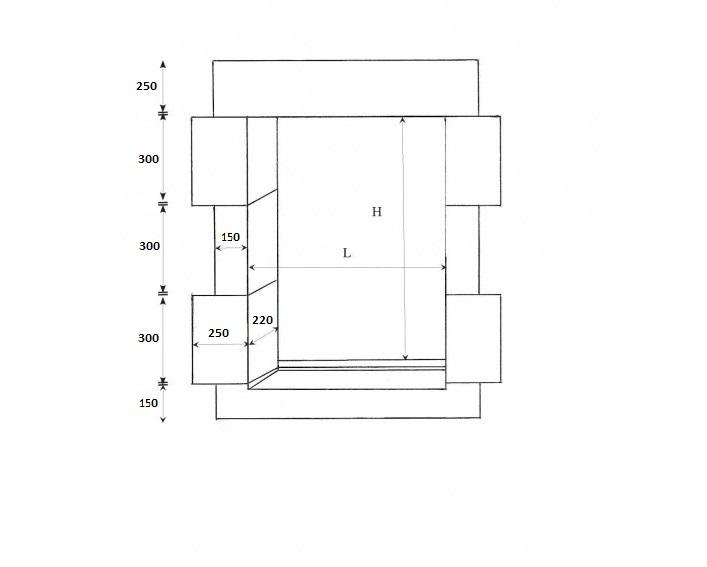

Hi,I am planning to do some work this year in July on my parents’ house which they bought 10 years ago, nothing considerable has been done on the house as they are can't afford the majority of the project that are present to them. I am taking on the project to help them out and to make a change, right now I am in the process of ordering the stone window surrounding set so it's ready for next week. I've talked thing out with my parent and we are looking to integrate the security roller shutter in the tight space behind the stone head of the window set so that box doesn't appear ugly. we are also planning to put a tilt & turn aluminium window in the two opening and put in a lintel above the 180 x 180mm shutter box. I was thinking of replacing the timber lintel to a steel beam with 200mm end bearing on each side. I will probably need to buy some arcow prop and some strong boy for this kind of job but don't know how many for a 600mm opening in a stone wall. probably 2, to support the timber floor joists inside and 4 for the window opening. Please let me know if am wrong.At the moment I need some advice on what lintel to purchase on your but need reassurance on the right lintel for the job.I will leave the detail below for your adviceSpan of opening: 600mmWall construction: Stone Wall (solid wall) no cavityMasonry height: 2m above, has roof load and floor joist bearing (2 storey)I will leave photos of the natural window surrounding set plan and a few photos of the 2-storey house.If you have any advice, I will be happy to listen

-

I have a MBC timber frame which part will be clad in stone but with the sure cav (50mm) between stone and timber frame having difficulty in finding lintels deep enough. Anyone know of standard timber frame lintels larger than the standard 100mm size?