Search the Community

Showing results for tags 'buffer tank'.

-

Hi All I am looking for some advice on improving the design of an existing ASHP setup. Sorry for the long intro. Originally the setup had a big 56kW HP feeding buffer tank & DHW, coupled with a gas boiler. The system runs both UFH and radiators. I was going through stupid amounts of gas, just to have enough water to have a bath. I ended up scrapping the gas boiler altogether and replacing it with a heat pump hater water cylinder, which paid for itself in 3 months. So now the main heat pump just does heating. We have also recently had a Linky (French Smart Meter) installed, which seems to have made the metering of electricity used go up dramatically. Also to add to the equation, our tariff has a red period - where the cost is 5 times normal (for 24 days a year) - these days we actually shut off the HP and just use the fire place. My plans are: Install a large buffer tank (2000 litres) - existing is 300L, to be used as a heat store, to heat radiators and UFH, even when Heat pump is off (Red days). I have read that buffer tanks are actually inefficient, or that they have a relatively small maximum size to be used. Also I think this will dramatically reduce cycling when heat pump is on. Connect the ASHP through a 3 phase condenser to the reduce the electrical loads and power factor that the Smart meter senses. I can add some pictures a further details a bit later I was just wondering if these plans seem reasonable or if I am barking up the wrong tree. Any advice will be gratefully recieved - Thanks in advance

-

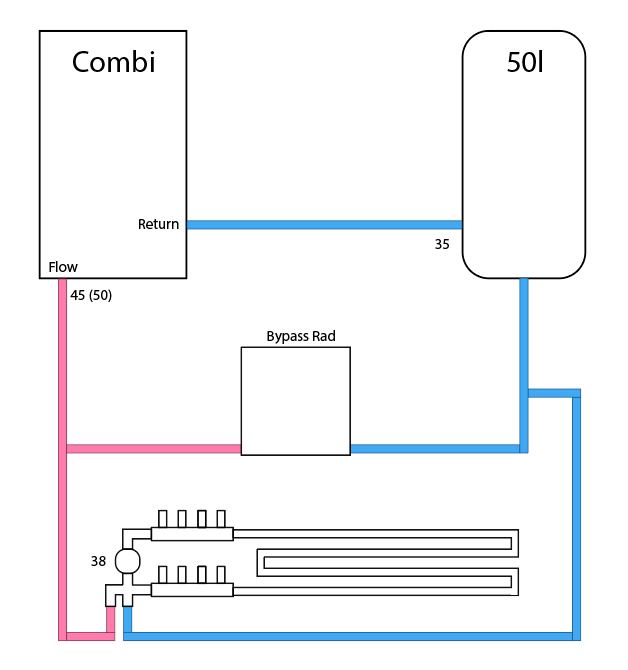

hello friends. Yet another "short cycling" thread sadly that id love some advice on. Not sure if its a) my plumbing b) my electrics or c) my lack of knowledge on it. System My system is a gas combi boiler Baxi 830 (or 800, cant recall) (30kw (or 24kw, id need to check the model), modulation 5:1, way oversized by plumber when i didnt know better), UFH downstairs and rads upstairs, on separate circuits via 2-ports etc. 4 loops, roughly 400m of 16mm, 2 zones (running as 1 zone currently)100/120mm centers in biscuit mix, 170mm PIR, flow rate via Salus auto-balance 2.5l-ish. On the advice of you wonderful gents i also fitted a buffer tank (50l) at the time of install with help from @Nickfromwales and @JohnMo, at the time i didnt have a clue about having to do this, i was uneducated on it (still am to be fair) Buffer tank saga I run the tank plumbed into the return as a 2-port and its only in play when the UFH valve is open. When the rad valve opens the tank is bypassed via a 3-port valve wired into the rad valve, everything's golden. I also run a small nearby bathroom rad as a bypass which runs independently as it is plumbed in before the 2x2-port valves. Ok, so i can run my system at the lowest setting on the mixer of 38 and have it run 24/7 keeping the house a constant 20/21. Or i can run it as a timed system with a mixer at 40/45 to make the house 21 in the morning and then 22 for the evening with a setback of 18. I have tried both ways and the consumption is basically the same, when its very cold outside it costs about a fiver to do this, other times 3 or 4 quid, great (i guess). Short Cycling So, i assumed this was all working correctly, the boiler is in the loft so out of sight, out of mind. I went up there on a whim to time my cycle and found out it was short cycling. What it does is the boiler gets up to its target temp, flames off (pump still running/over-run?) for exactly 3 minutes while the temp drops, then flames on and repeat. It seems to do this no matter what i set the boiler flow to. When it fires up with a cold buffer it takes a good half an hour for the return temp to come up before the above happens, but when warm it cycles as below: UFH mixer Boiler flow Return Flame on Flame off /buffer temp 38 40 (45) 34 0.47 3.00 38 45 (50) 35 1.40 3.00 38 60 (65) 49 4.20 3.00 after i ran it at 60 for a while i then turned the boiler flow down to 40 and it took a good half an hour for the buffer to empty while being pumped around the system by the boiler, satisfying the UFH demand. This i what i thought i was building (what id like to have?), the boiler fills up the buffer over 10 minutes then it takes 30 minutes to empty, and repeat. Obviously it doesnt, the boiler is always trying to satisfy the heat it is set at, duh, its a volume buffer not a storage tank. So my question is, is this running as its meant to? i thought the addition of the buffer was meant to alleviate the short cycling, which it does but only if running from cold so its short lived. Im not sure what i was expecting but as the 3 minute flame off is always exactly 3 minutes thats obviously an anti-short cycling function of the boiler kicking in. I mean its only costing a few quid each day but it cant be good and is obviously a failing somewhere on my behalf. I have attached a simplified diagram below to maybe help explain my system. What have i done wrong guys, do i just need more volume? run the mixer hotter to bring my return down? Unfortunately i am going through a redundancy process (sob story) so my build is on hold so id really like to see what i can about this if anything. Thank you people.

-

Our heating system is currently designed for ground floor UFH and ASHP. So far so good. It has always been in the plan to fit a buffer tank. I'm now beginning to re-think the buffer tank and remove zoning. To give some context, we have a block house on insulated slab and <3kW peak heating load. Floor temperature will change very slowly hence individual zone control seems to make little sense, even with solar gain moving around the house. We have about 600 metres of UFH pipe in the floor at 200 centres. I see from discussion here that there is a school of thought that questions the conventional wisdom of installing a buffer tank to stop short cycling because there is already sufficient volume in system. And so it may be more efficient to remove the buffer tank all together and connect the ASHP diretly to the UFH manifold. Is this a contentious area, or is this well established? If we delete the buffer tank, are we then limited to a maximum of one UFH manifold? I am toying with the idea of another manifold on the First floor, but only for some additional cooling, or maybe heating under bathrooms. What about hydraulic separation? I would need a pump at the manifold of course, so what if this manifold pump runs at different flow rate than the ASHP pump? How does that work without seperation? If I did decide to add another manifolfd for some UFH upstairs, would that mean a buffer tank must be included? Our plumber will be horified at the suggestion of dropping the buffer tank, so I need to be certain of this before I give him his next heart attack.

- 18 replies

-

I am in the process of designing (with architects!) and commissioning a small low-energy house which will rely mainly on solar pv for energy. There is no gas at the property. I have over 15 years experience of solar thermal and solar pv. My current house uses solar pv exclusively for hot water for more than 7 months per year, uses gas for ch & backup hw for colder months. My current 3 immersion design cylinder has proved very effective. I have trawled through various heating and dhw designs including thermal stores and multi-tank solutions but cannot reconcile the different requirements (eg thermal stores need a good temperature gradient to provide dhw - heat pumps provide 55º as a working maximum). I have also noted comments on this forum. (“Hot water and heating are different – keep them separate!”) However I’m still looking for an efficient & effective solution. I am considering using a large unvented cylinder (say 500 litres) which will also act as a buffer for a heat pump and a thermal store for underfloor heating. For at least 8 months of the year the total input would be from solar pv through immersion heaters. For the colder months there would be the possibility of input from a heat pump. Primary heating would be through 3 immersion heaters. I have included a diagram. I see the following as advantages : 1. A single tank with straight-forward plumbing. No complex valves or diversions. 2. Separation of circuits for input/output. Antifreeze needed only in the heat pump circuit. - Better heat transfer to UFH with water than with antifreeze mixture. (and much less of it) 3. Ability to maximise use of solar pv (8kW) throughout the year. 4. Possibility of running as a fully electric system without heat pump - under consideration for at least one year to assess relative costs. Also provides alternative heating if heat pump fails. 5. Typically : we boost heat in the mornings (before 9.00) and in the late afternoon/early evening. Background temperature maintained at other times (although with a good store in the slab this will become less pronounced). Best efficiency from an ASHP will be when the outside temperature is highest and the best use of solar pv will be between 9.00 and 17.00. So having a facility to store heat at these times will maximise both efficiencies. I recognise one potential problem: In our current location, with excessive water hardness, cylinders frequently deposit more than 0.5kg calcium salts per year. We have completely avoided this by quality water softening and would do so in the new location. Although the physical design is simple the efficiency will depend on the control circuits. I propose to design & program these myself rather than rely on the current commercial provisions which seem to be over-complicated but still limit options to those provided by manufacturers. All of the plumbing would be installed by G3 qualified tradespeople. So I would welcome constructive guidance … 1. Is there any commercial system which already follows these lines which I’ve missed? 2. Has anyone on this forum taken a similar line – with what results? 3. Are there any genuine down-sides which I’ve missed?

- 11 replies

-

- uvc ( unvented hot water cylinder )

- buffer tank

-

(and 2 more)

Tagged with:

-

Needing to focus on my next project after my UFH fiasco and being in a holiday rental place where the DHW is very hit and miss reminds me that I need to get some specs laid down before I start ordering stuff! Having read so much over the past couple of years, I feel a lot more informed but also a bit bamboozled at the same time. UVC or TS, buffer tanks, what size..... So my main questions (so far): 1) what type of gas boiler to go for? 2) Thermal store or UVC? 3) Buffer tank needed? My setup will be: 4kw solar PV Mains gas 2 UFH manifolds (upstairs and groundfloor - so I can choose the flow temps accordingly to get the maximum comfort levels) Room stats in all areas 2 Bathrooms (2 showers, 2 baths) MHVR Although not going to be a passivhaus, I’m hopeful it'll be a bloody whole let better than your standard newbuild: 2 SIP extensions 300mm EPS floor insulation 3G windows/doors 100mm EWI on existing house DHW requirement: 2 adults and two soon to be teenagers (so they will hardly wash reducing the DHW figures a bit) 2 morning showers 2 evening baths Hot water for washing up (though may get a boiler-type tap for most hot water needs in the kitchen) Occupancy: Wife and kids out and I although I work from home, my office will be one of the sheds out the back so main house can either be set to off or very low temps during the day. UFH demands: Groundfloor: Water volume: 129L; Estimated loading: 9.45Kw Upstairs: Water volume: 25L; Estimated loading: 2.03Kw BOILER QUESTION: Before I start getting plumbers out to fit a boiler system, I’d like to get people’s advice on whether to go for system or combi. Combi = don’t need a water storage cylinder = no need for cistern in loft = combi boilers don’t supply enough hot water = better to use a separate cylinder for the hot water supply. = combi boilers can be quite noisy. System = Store hot water in a cylinder, so they can feed several outlets at once at mains pressure. = no need for a cistern in the loft and the expansion vessel is built in. = Flow rates will be high as water is delivered at mains pressure, and hot water is instantaneous. I'm thinking to go for a system boiler at this stage (easier/quicker install) and then to use excess PV with the cylinder. THERMAL STORE OR UVC? My thoughts so far are to have a 300L UVC fed partly by the solar PV during the day (using an Immersun type of device) with maybe E10/E7 at night and then also the gas boiler. I would end up with two circuits – one for DHW and one for UFH. The boiler would kick in for the UFH when the UVC doesn’t require heat. BUFFER TANK? I'm also thinking that if I go for a UVC rather than thermal store (from what I have read on here) I would need a buffer store seeing I will have UFH. But I've read that if I opt for a TS, that can be my buffer tank also. So perhaps I should go for a TS rather than a UVC? Confused.... Hoping someone (AKA: @Nickfromwales etc) is able to assist..... Thanks, OB

- 60 replies

-

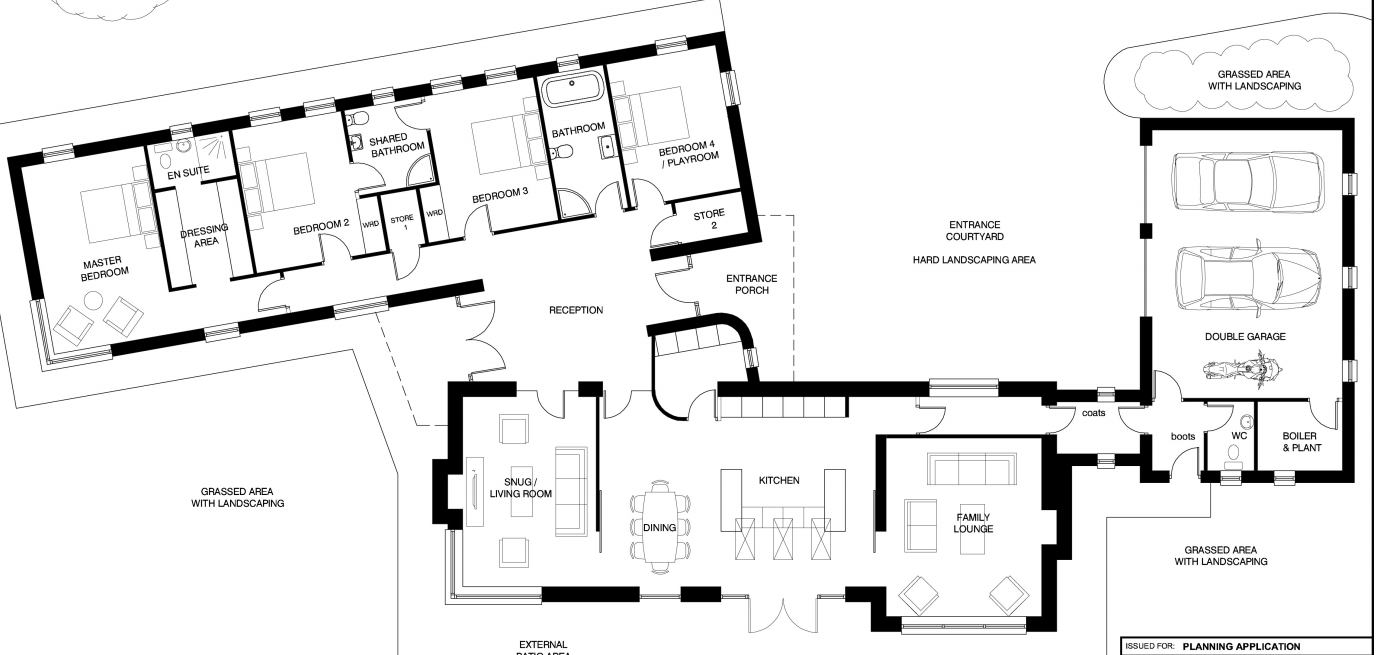

I have been avoiding this post for a while and also been busy doing other things at the house. I need to sort out my heating design and it is proving difficult with varying opinions here in the land of the hotpress. I have a plumber who I am relatively happy with and comes highly recommended we just need to bottom out the design somewhat. Above is the floor plan and I have posted on this previously a long time ago, never thought it would take us this long to get to the point we are at. We are going to have UFH throughout along with towel rads in bathroom/en-suites, feature radiator in reception (I don't anticipate this putting much heat out) and provision for radiators in the garage. This will all be fed from an oil boiler (gas is not an option, ASHP I have ruled out and PV wont be happening). I understand that oil and UFH are not conducive for optimum performance but measures can be taken to alleviate this. The default position with almost all plumbers and heating designers here is to just feed the UFH via blending valve straight from the boiler, I hear @Nickfromwales scream what about short cycling on a boiler that cant modulate like a gas one (I have read plenty on here already). Some just don't get it is all I will say. Others agree to disagree. My options are as I see it:- Oil boiler with buffer and UVC. Question here is what size of buffer? It was suggested to me 500L but that was then going to also feed a UVC which I couldn't quite get my head around. Other option as I understand would be a 400/500L thermal store to do the lot. Any time I raise this in discussions no-one understands why I might do this if I have no wood burner etc dumping heat into it. Are there any other options? I dont really understand it all myself and my head has gone to mush with all the reading I have done. I fear my plumber may run for the hills if I dictate too much of the design to him. Please help!

- 21 replies

-

- ufh

- buffer tank

-

(and 2 more)

Tagged with:

-

Right.. so following the post where I put the planned controls and layouts I have been thinking about the ASHP temperature control mechanism for this. You can see from the schematic there are two pipe stats that are directly linked to the ASHP control box. In the ASHP instructions, this is used to regulate the water temperature in the system, and as I want 2 different temperatures then I need 2 stats. The unit is supplied with a standard Siemens RAM1 pipe stat which seemed ok until I checked the differential - 8K +/-3K...!!! So at 37c set point, I could get a range of 32-42c which seems a bit excessive. I am trying to keep this as "off the shelf" as possible, and looking at specs its clear that 4K differential is the norm on these things unless you go upwards of £35 per device. I can get down to about 2.5K with one of these Computherm Capilliary Stat which seem pretty good. ( @JSHarris didn't you use Computherm..?) but I'm still querying if it is "good enough". The house isn't passive by any stretch but will have good air-tightness and a well insulated roof, with a January heat load of around 1180KwH. Overshooting the 35c stat will only result in the buffer being warmer than needed as the UFH will be set to 32c flow. I could go with something such as one of the many £8 DTC-100 based controllers from China and get myself 0.5C differential control on the water temperature but I do wonder how the ASHP will cope with this, and what the benefit will be as there is 9m of pipe between the ASHP and the sensors. I'm not going down the custom code / build route on this but I'm trying to build the best "analog" system that I can without spending a fortune but I'm left questioning how good do I need to go..??

- 22 replies

-

- ashp

- thermostats

-

(and 1 more)

Tagged with:

-

I am moving towards finalising the design of the Heating/Cooling and DHW system. The house will have UFH/cooling supplied from an inverter ASHP that can also cool the floor (and supply cool water to an MVHR duct cooler), heat load of 3.4kW over 419m2 from PHPP. However we have a high DHW requirement (after long discussion on the previous forum) I have got it down to 27 L/m at ∆T of 44K with a usable capacity of ≈400L. (5½ bath house). I was looking at having a separate buffer tank for the UFH (200-300L) which could also pre-heat the DHW (a la Jeremy's layout, just bigger) followed by a Thermal store (300 – 500L) to supply the DHW (We have Mains Gas so boiler power). This would separate the 2 systems (recommended by most on the forums) and allow me to run the TS at variable temperatures (50oC – 80oC) depending on required loading (low occupancy – high occupancy), whilst eliminating the Legionella problem with a UVC at low occupancy. I would also cross connect the heat generators so the ASHP can provide low grade heat to the lower part of the TS and the boiler can supply the Buffer during ASHP high load/failure. However I am now considering just one larger Stratified TS (750 – 1000L) to cover the whole system. This would make plumbing and specification easier and theoretically the thermal losses from one large tank should be less than 2 smaller tank. eg. AKVATERM AKVA GEO 300 64W AKVATERM AKVA GEO 500 75W AKVATERM AKVA GEO 750 89W AKVATERM AKVA GEO 1000 96W So the 300 + 500 gives me 139W (although the 300 would be at a lower temp so less loss). Yes I know losses will be higher but as a guideline. I have been looking at the Sunamp Stack but it is only available as a complete stack 40kWh and would not support the low temperature of the ASHP (requires high temp to charge > 58oC). What would the collective experience go for with regards separate tanks and giving individual (if cross connected) systems vs one all singing (overall lower loss) tank?