bungledlow

Members-

Posts

11 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

bungledlow's Achievements

Member (3/5)

1

Reputation

-

@markocosic can you elaborate on both of these points? What do you mean by "all days units"? These were on my shortlist, but now you have me concerned.

-

Hello I have a timber front door with sidelights either side. The sidelights are already installed, I understand this is standard practice for transport to keep the frame square. See images. However I now need to install the door, which was fine for the back door without sidelights as I could screw through the frame. The sidelights are in the way for this door though. I have found that you could use metal brackets instead of screwing the frame however I also would like to remove the glass to install multipoint lock keeps. Is it a case of using a putty knife to prise off the bead around the sash? Or just get a glazier to do it? Presumably it is normal to have to do this with sidelights if they are delivered installed? (Feel free to move to the "doors" sub-forum if that's more appropriate!)

-

Laminar Flow in Ground Collector Array

bungledlow replied to bungledlow's topic in Ground Source Heat Pumps (GSHP)

I was referring to the subject matter of the forum rather than the members. I would never imply people here are simple minded... its self evident ? -

Laminar Flow in Ground Collector Array

bungledlow replied to bungledlow's topic in Ground Source Heat Pumps (GSHP)

Significantly more expensive Going this route is more for technical elegance and the intellectual challenge versus the admittedly lower financial and installation requirements of ASHP. The decision process was based on the fact being a new build it seems like a wasted opportunity not to make the most of a clean slate design given we have the land available with perfect soil conditions and a digger to do the groundworks. Add in the slightly higher efficiency vs ASHP and the opportunity (however insignificant) to recharge the ground when the pump is in cooling mode, acting somewhat like a thermal store, and it feels like a long term investment opportunity, albeit not as financially sound as going with air source! -

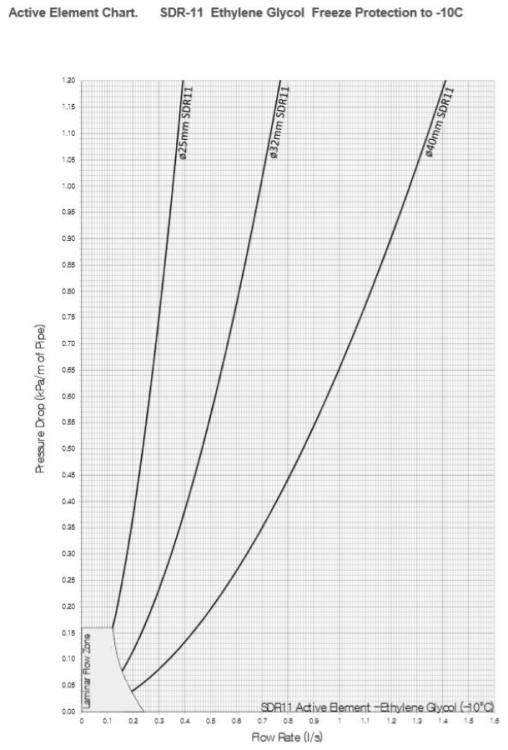

This might be too technical for this forum but giving it a go anyway on the off chance there is someone here who understand fluid dynamics more than me! In designing a ground source heat pump system, specifically sizing the diameter of collector array pipe, the technical guidance is straightforward but quite grey in some areas. My understanding of the design process: Header pipes - Laminar flow is good as you don't want turbulence increasing heat transfer to the pipe wall Array pipes - Laminar flow is bad, lack or turbulence means low heat transfer to the pipe wall Whether your array is in laminar flow or not (and the pressure drop over it) is a function of the pressure drop per metre (itself a function of roughness and diameter) and flow rate: Pressure drop per metre of pipe is a constant for the pipe diameter you use Flow rate is a variable set by the heat pump chosen and is referred to as "minimum ground side flow rate". Put both of these numbers on each axis of the chart below and you get your pressure drop. (p23 of MCS Guidance Document - Hydraulics Design Guide for MIS 3005) More often than not its marginal or very close to being within the laminar flow zone in the bottom left. So by reducing the pipe diameter you can cause more turbulent flow but you also have to contend with the overall pressure drop and whether the pump can deal with that. The difficulty I have found is not the overall pressure drop but actually getting comfortably out of the laminar flow zone due to the low flow rates quoted by the pump manufacturers. Question: What does "minimum ground side flow rate" of the heat pump actually mean? In practice will the pump be running harder than this "minimum" because modern inverter pumps can vary their speed - is this just a theoretical worse case scenario for design purposes, meaning we are safe even if our numbers are marginal here? Decision: We have been advised that we should have bigger 40mm pipes, and there was some surprise from this advisor that some of the big names had specified smaller diameter (25-32mm) pipes. However when running the numbers, a smaller diameter would make more sense so that turbulent flow would be initiated at lower flow rates. The advantage to using larger pipes is that https://www.gogeothermal.co.uk/ offer a crack resistant pipe in 40mm that does not require sand bedding, reducing time and cost of install and improving performance due to direct contact with the surrounding clay soil. Appreciate any advice/interpretation anybody can offer.

-

Cable between cabinet and consumer unit

bungledlow replied to bungledlow's topic in Electrics - Other

54mm (2") as requested by UK Power Networks. Difficult to get hold of, nobody seemed to offer them, but Travis Perkins managed to get them in the end -

Cable between cabinet and consumer unit

bungledlow replied to bungledlow's topic in Electrics - Other

I suppose I should ask the electrician then, but I think I know the answer - 5 core, the most expensive... -

Cable between cabinet and consumer unit

bungledlow replied to bungledlow's topic in Electrics - Other

Thanks, that all makes sense now. They did not leave that cable, I just snapped it before they put it down the conduit so I could see what I was getting for my money! Yes, exactly this. I will purchase a new 4 core SWA cable then and put it in the conduit ready for the electrician. -

Hi, this may be a case of "ask your electrician", but I was hoping I may be able provision the main supply cable to the house without connecting it to the consumer unit as we want to get all the digging done in one go. We have a cabinet with a 3 phase supply, each 100 amp. The DNO used 3 core 35mm SWA (see attached) for this from the joint bay to the main fuse. It is a PME (TN-C-S) system (see attached) so my understanding is the Neutral and Earth are essentially the same. What I don't understand is how the Neutral/Earth is supplied through the 3 core cable. Do they use the armour? The house is another 50 metres from the cabinet, calculators show 35mm cable should be sufficient for this. The question I have is how many cores are required? 3 like the supply cable, 4 to carry the Neutral, or 5 to carry Neutral & Earth? Any advice appreciated

-

Hello, just introducing myself and hope to get some support on some technical matters, mainly electrical, so i will post in the appropriate forum for those questions. Also interested in any local materials that may be going cheap at the end of any body else's project... tiles, MVHR pipe, cable etc. Hope to be able to help out on any questions too, or give some forum members first dibs on our leftovers.