NCXo82ike

Members-

Posts

76 -

Joined

-

Last visited

-

Days Won

1

NCXo82ike last won the day on November 21 2025

NCXo82ike had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

NCXo82ike's Achievements

Member (3/5)

12

Reputation

-

yes, I think we should be able to do a reasonably comprehensive job over the beams and between the joists.

-

That is amazing, thank you. Getting great value from this forum! We will be doing some internal insulation on the brick wall above and indeed all the old solid walls. Insulating lime plaster where there's any chance of moisture in the walls and MVHR to extract humidity from the internal side. The plan is to bring those to U value of ~0.60. Then new walls and ceilings are just to modern building regs, not passive house standards. Ground floor is liquid screed on 150mm PIR on ground bearing slab. UFH in the screed and low profile overlay on new chipboard flooring in upper floors.

-

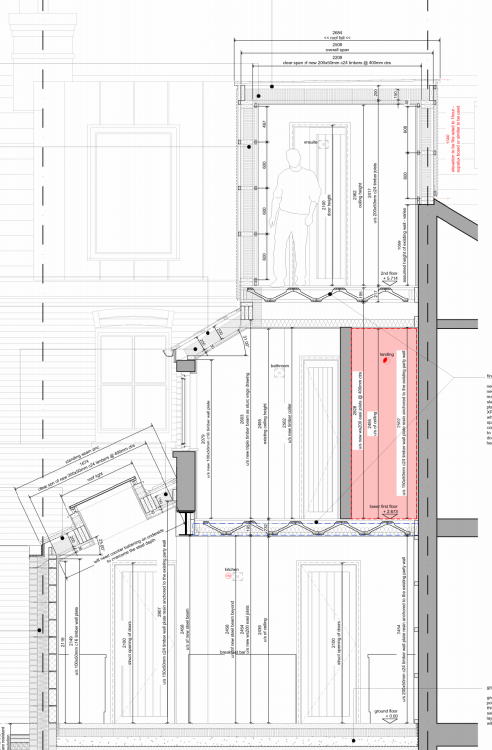

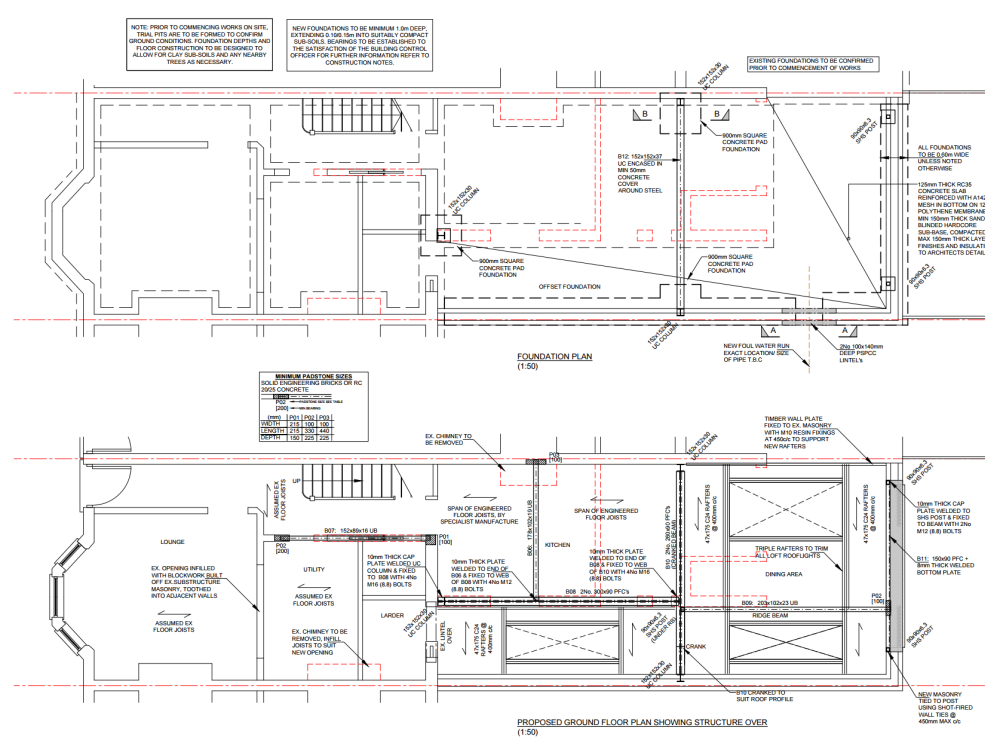

Thanks Nick. Here's the SE drawings, relevant section of regs drawings, and photo of the key parts . The steels B06 and B10 form cold bridges with the ground below. They support a solid wall above. You can see blockwork internally but we had to rebuild a section and couldn't make this a new cavity wall. The webbed joists hang off those steels and pocket into the old solid brick walls. So it's an all an inherent compromise- but I want to take sensible precautions to stop the kitchen vapour condensing on cold spots.

-

Thank Nick, does that mean we shouldn't insulate the beams then? They have external solid walls bearing on them so I (as a total amateur) consider them a cold bridge/condensation risk? Perhaps all academic given that we're getting crittall-style doors as a massive thermal bridge

-

It's a shame this level of detailed knowledge isn't common

-

First floor. We've got a new insulated slab over the whole ground floor

-

Some joists come off the steels, so these will have cool ends- the spray foam will hopefully stop vapour getting to condensation spots. We have the same situation with old joists in the solid walls. I've seen some recommendations to avoid internal insulation at the joist pockets to keep these warm, and others to insulate and tape around the joists for a continuous VCL.

-

No decoupling, a lesson for next time around. Not something discussed by the architect or engineer, and by the time I understood it we were too far along. Thanks for the recommendation- boxing in and spray foam sounds great.

-

Thanks John, on that basis my question is whether there's a reason not to use spray foam since there's a lot of complex junctions, joists etc

-

We have most of the steelwork up in our wraparound extension and loft conversion. 1905 mid-terrace, solid wall construction. We have picture frame steels sucking heat into the ground and steels bearing on to (and/or supporting) cold brick walls. I'm looking to minimise the impact of cold bridging. The wraparound is brick and block with mineral wool cavity, pitched vented roof. The loft conversion is timber, vented cold roof (unfortunately necessary). Priority 1 is to avoid condensation, priory 2 to reduce heat loss. No cold steel near bathrooms, but plenty near the kitchen in the wraparound. The builder suggested PIR or mineral wool around the beams, but I worry if we insulate without a vapour barrier against the steels it will worsen interstitial condensation? I wonder if spray foam is a sensible way to do this, cutting the cold bridge with a continuous vapour barrier I can tape against other membranes. I've sent the horror stories but get the impression the issue is where critical ventilation e.g. cold roof is compromised by the spray foam. Other relevant measures are: -internally insulating solid walls (planning on vapour-open with thermactive plus wood fibre). -windows uprated -We'll be getting as airtight as reasonably possible -MVHR system fitted which I will control based on internal humidity Grateful for any thoughts- couldn't see similar in the forum surprisingly

-

Help with leaking MDPE compression to water meter housing

NCXo82ike replied to NCXo82ike's topic in General Plumbing

So looking at it yesterday it seems like the thrust ring, at full thrust, doesn't make contact with the o ring I took from new mdpe coupler. The new o ring looks to be 3mm thick (calipers time in the daylight) so I'll try upsizing it. The only other option I can think of is there was some sort of spacer between the thrust and o ring, or an o ring with a weird oval section. Typical plumbers' merchants aren't familiar with the fitting- I have been recommended a 'civils' merchant who stock the Binary box itself -

Zombie thread, but in case it's of interest to anyone- this was the building fix. The neighbourliness part was almost the hardest part. Our neighbours weren't aware of this issue. After raising it several times as a non-urgent but upcoming issue, we then raised it when we were going through formal party wall notice for other things like chimney removal and our loft conversion. We have a deed saying we owe them enclosure costs for the wall built on the boundary if we build on it- they suggested they would waive that. We pointed out that when we built the extension we had planning permission for, or even if we built a direct copy of theirs, there would be a pooling issue from the water directed backwards. So there needed to be a fix. We calculated the enclosure costs based on 1/2 of what it would cost us to build that same wall now (using our builder's quote). They had a quote from their own trusted builder (who built their extension) to infill the gap in the wall and redirect the gutter- seemed somewhat high but it's a small firm doing quality jobs. We offered the use of a skip bag already on our property to save on skip hire and gave them bricks from my collection as pragmatic. We then insisted on paying the enclosure costs but insisted that the fix was done. Conveniently the enclosure costs were just above half the remaining builders quote. Our neighbour (retired solicitor) drafted a memorandum of understanding, enshrining that we were explicitly paying owed enclosure costs and they were funding the remedial works to their extension, with the accompanying contract, warranty, responsibility etc being completely theirs (although the wall remains a party structure). So a blend of goodwill and pragmatism plus sticking to the agreements, but all dressed up as down-the-line obligations. All done with tea and cake in their garden. Very grateful for all advice- needed a robust understanding of where we stood (which this forum enabled) as a foundation for that amicable outcome.

- 16 replies

-

- 6

-

-

- party wall

- gutter

-

(and 6 more)

Tagged with:

-

Asking builder for steelwork invoice?

NCXo82ike replied to NCXo82ike's topic in General Self Build & DIY Discussion

Simple reason for the name: when I set up my BH account I was looking for strategic advice on how to approach a party wall situation. All now sorted amicably (visible in my history ofc). Domestic client yes- very interested but no professional expertise. Being done under a RIBA contract. The drawings clearly needed steel but the quote specifically excluded steel and steelwork pending SE calcs. This was the same for 5+ other well reputed builders who quoted. Overall- no I don't think we're being ripped off either in total or on reflection on steelworks. So far we're mostly on demo, but the groundworks and 4 steels installed so far have been accurate and tidy, site kept clean, neighbours happy. The steels are hand heaved into a mid terrace with front access only so it's a lot of work. For context this is about 10% of the total builder's bill and everything else has either been bang on the quotes or clearly justified e.g. BC wanting extra foundation depth or us taking out another chimney. So per Nick, it is sort of on our heads. In the same situation again I'd ask for the fabricator's invoice upfront. Just to register how excellent a resource BH is- thanks! -

Asking builder for steelwork invoice?

NCXo82ike replied to NCXo82ike's topic in General Self Build & DIY Discussion

This was a very nice sense check, thank you! -

Asking builder for steelwork invoice?

NCXo82ike replied to NCXo82ike's topic in General Self Build & DIY Discussion

Thanks for such quick replies. To clarify the works are already underway, all sticking to the original quote other than what are obvious extras. The builders ordered the steels from their usual fabricators. Several are already installed. So we're basically stuck with whatever the cost is. Asking for the invoice is basically peace of mind that we're not being overcharged. I don't know if that's a usual thing to do, or if the builders would take offense at this and we'd upset a good relationship. Appreciate it would have been much better to have this agreed before work started but this would have lead to at least 6 months of delay.