-

Posts

355 -

Joined

-

Last visited

Everything posted by Tony L

-

I think this is the best strategy if it works for you. I bought a heat pump TD for my mum. We installed it in her garage. I heard a reputable source explaining on the radio, TDs fill the air with microplastics & other pollution. I’m not having one in my house, although I plan to have one in an outbuilding, so I won’t have to breathe all the crap that comes out of it; also, my MVHR filters will go longer between changes & my utility/plant room (they’re the same room) won’t overheat so much in the summer.

-

Sorry, I can't help with this, but I must congratulate you on moving in, having completed your build so quickly. You're an inspiration to us all. & thanks for documenting your progress on here too - it's a real help to those of us who are not there yet.

-

is there a better kind of roofing / cladding batten?

Tony L replied to Alan Ambrose's topic in Building Materials

Yes. Dura Composites, who sell very nice, expensive cladding, will sell you some special aluminium batten bars. -

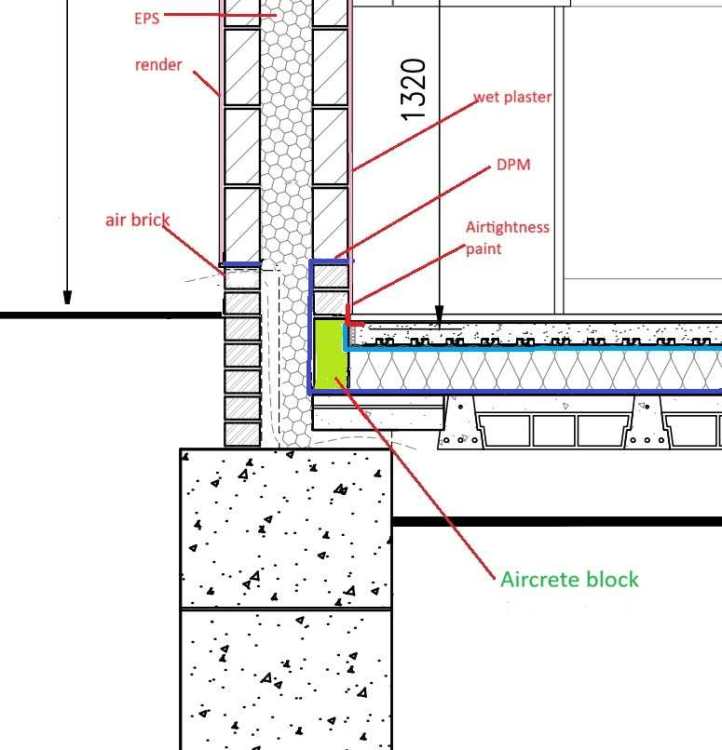

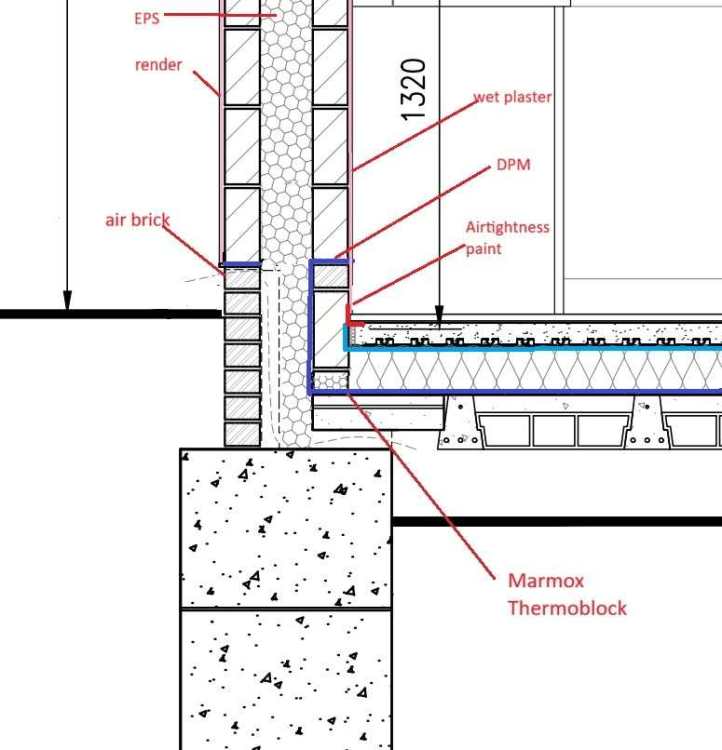

Aircrete version: When I did a cost analysis some time ago, the Marmox Thermoblocks didn't seem too pricey, for the perceived benefit. When I find time, I'll dig out my figures.

-

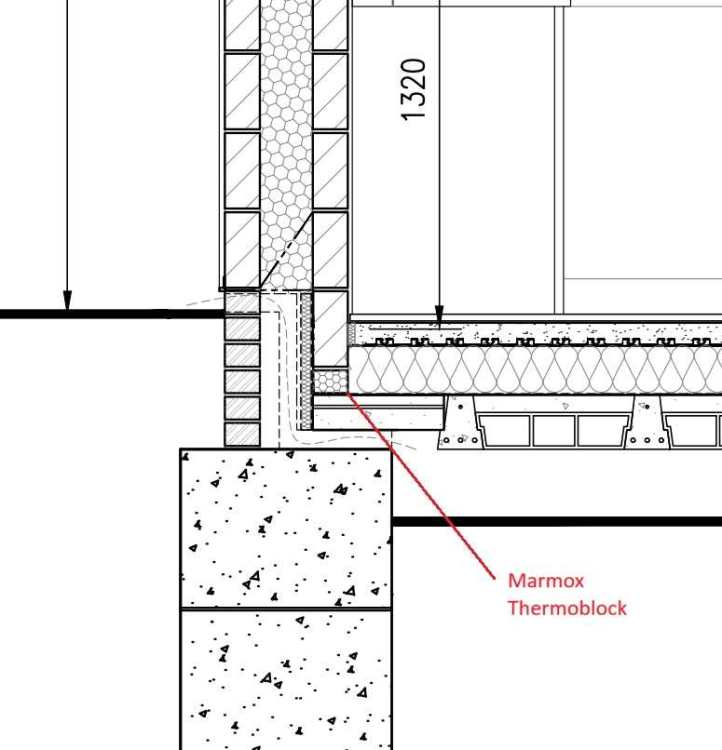

I have a very high water table, so I think this will likely make the ground colder than if the trench blocks were sat in dry ground. My trench blocks are going to be almost permanently damp, & I note @Iceverge's point about Aircrete blocks having to be kept dry, which is another reason I can’t copy the @Iceverge detail. I’d be grateful to hear comments on these two ideas, below. Could I wrap the DMP around the outside of the bottom of the inner leaf construction, as shown in blue? & sorry for the thread drift, @flanagaj. I hope you find my problem interesting & helpful, as you consider your build.

-

Thanks for your input @Gus Potter. When I say, “I designed the house.”, I mean, I did all the planning permission drawings & passed these over to an architectural technician, together with some notes about materials & build method (the Thermoblocks were part of my spec’). The AT has done the drawings my detail drawing was taken from, above. I expected him to do a lot better than this. Now I am spending hours & hours teaching him how to do his job properly so he can improve the drawings before they go to building control. My intention was to have EPS beads filling the cavity, with these going all the way down to the trench blocks. I imagined the EPS installer would drill through the inside leaf near the floor to fill the area below the tray. If I don’t need a tray & I can have two separate DPCs that would seem to me to be a better solution. This was suggested to me on an earlier thread, but I thought the 2 separate DPCs suggestion was just for below my windows. If we can use 2 separate DPCs the whole way round the house, that would be great. Are you sure omitting the Marmox blocks is a good idea? This is going to mean all my walls will be sucking heat out of the house straight into the ground. I can’t follow @Iceverge’s detail above (thanks for putting this up, @Iceverge) because I’m building my inner leaf off the top of the B&B, which has already been built. Here’s a picture of it during construction. As discussed here previously, the cowboy builder sat the B&B on trench blocks, instead of on dense blocks (which were on the drawing), so there’s no cavity beneath the level of the B&B, & although he put the beam ends on DPC, he then bridged the DPC with mortar - see below. The bit on the right of the picture, with the light coloured slips, is where the air brick periscope feeds air into the B&B void.

-

I shouldn't think so, but I don't really know, because I didn't learn about ground bearing slabs before I designed my house. I should think with a ground bearing slab, you'd have a continuous platform of insulation to separate the top part of slab (including the bit the walls are built off) from the bit that's in contact with the ground. In my case, I have concrete foundations with trench blocks, & the trench blocks support a beam & block structure, so my inner masonry leaf would have a direct connection to the ground, through low R-value materials, were it not for the Marmox blocks. Perhaps I should have left this question for somebody more knowledgeable than me to answer, but it seemed to be directed at me.

-

That's exactly what I have planned for my build. I also have a couple of dense block internal walls which will sit on Thermoblocks. One of these will be built from blocks laid flat, so it will be 220mm thick & will have 220mm Thermoblocks beneath. The idea is, if there's any money left, I can hang a floating staircase from this wall. & I'll have super THERMAL MASS - there, I said it too. Now we'll both be in trouble when @SteamyTea reads this thread. Here's my detail. Yes, I know my Arch Tec has drawn the air brick at the same level as my patio, with virtually no insulation below DPC level & the periscope sitting in the middle of the cavity instead of up against the outer leaf. I have already told him off. He really is rubbish. & I engaged him in May, & I'm still waiting for my second draft drawings.

-

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Tony L replied to fatgus's topic in Heat Insulation

This must be why Veka's T&Cs say, "In the absence of any express warranty to be specified by the Seller in respect of Goods which are not “white PVC -U profile” no warranty shall be given in respect of the Goods.". If you want a warranty for a colour, you have to ask them for one, & I don't suppose it's going to be 10 years, which is what they're offering for the white PVC-U. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Tony L replied to fatgus's topic in Heat Insulation

I had a look at the Veka website, earlier today, following @Iceverge's tip, above. They offer some colours in what's called "Feinstruktur" finish, which they say looks like aluminium. -

Yeeessss we bloody done it.

Tony L replied to Russell griffiths's topic in General Self Build & DIY Discussion

Well done, Russel. That looks fabulous. I hadn't realised you weren't already in. -

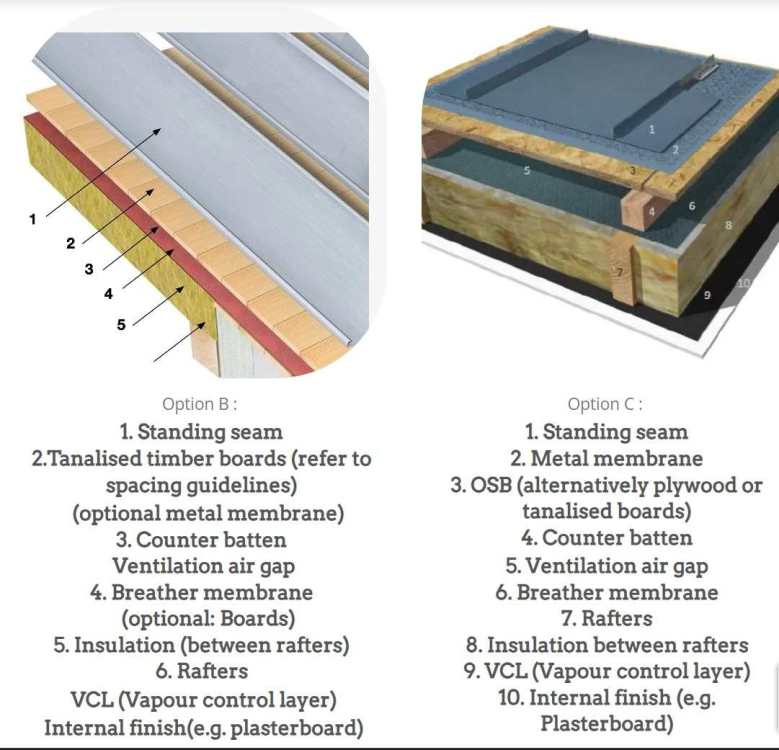

This has got me thinking: due to planning constraints I've ended up with a messy roof design - I can likely go for wide gaps between the sarking boards on the sections that will likely never be walked on, & this will give a worthwhile saving, but I'm guessing my standing seam will be going on before I get onto cladding the dormer faces & cheeks, so I'll need the adjacent roof sections to be more robust.

- 19 replies

-

- vapour control layer

- standing seam

- (and 9 more)

-

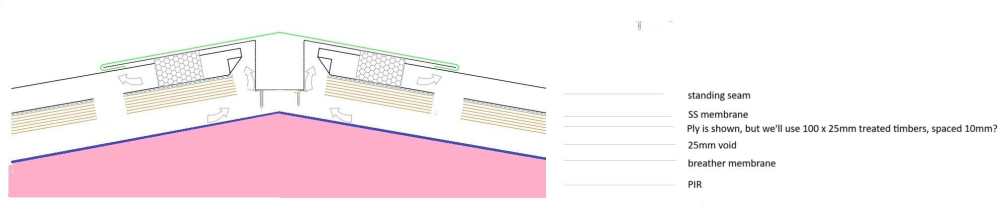

Russell's 100 x 25 is probably a better suggestion than my 150 x 25 - assuming there's negligible increase in flex. The 100s likely save more in materials than they cost in additional labour. Furthermore, I can see that fitting these is a job that I'd enjoy doing myself, so it doesn't matter too much if they're going to take an extra day.

- 19 replies

-

- 1

-

-

- vapour control layer

- standing seam

- (and 9 more)

-

That's good to know. This is something like what I have in mind for my build (left side image). What this drawing doesn't show clearly is, there's an air gap above the red membrane (4). The air gap starts at the gutter & goes all the way up to the vented ridge. Also, I'll leave gaps in between my 150 x 25s - the gaps will be as big as I think I can get away with & still be able to walk on the roof without any risk of damage; the bigger the gap between each board, the cheaper the roof.

- 19 replies

-

- vapour control layer

- standing seam

- (and 9 more)

-

@SimonD didn't suggest woodfibre. My understanding is, woodfibre sarking boards are used when extra insulation is required, & they're likely held down onto rafters with softwood battens, so their sub-optimal pull out qualities aren't a concern. If you already have a ton of Kooltherm on your roof, as your drawings show, you don't need to worry about another few mm of insulation. I think @Russell griffiths is suggesting 150mm x 25mm treated softwood planks. These don't fully cover the roof - I've seen them installed with 10mm or more gaps between each plank, so they support the standing seam & the gaps assist in drying, should the wood become damp. I'm no expert, so listen to others' views, but I'd want some ventilation under the standing seam. I'll try to find a picture... Of course, the problem with the treated softwood 150 x 25mm is, the materials cost is going to be more than OSB (or even 22mm ply) & they're going to take a lot longer to install, as well. I haven't done the maths yet - I need to, because this is exactly what I'm planning to do for my roof.

- 19 replies

-

- 2

-

-

- vapour control layer

- standing seam

- (and 9 more)

-

Thank you very much @Gus Potter & @Iceverge for your recent posts. I have so much to do before I go away, I'm going to have to leave this now, & pick it up again the week after next.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

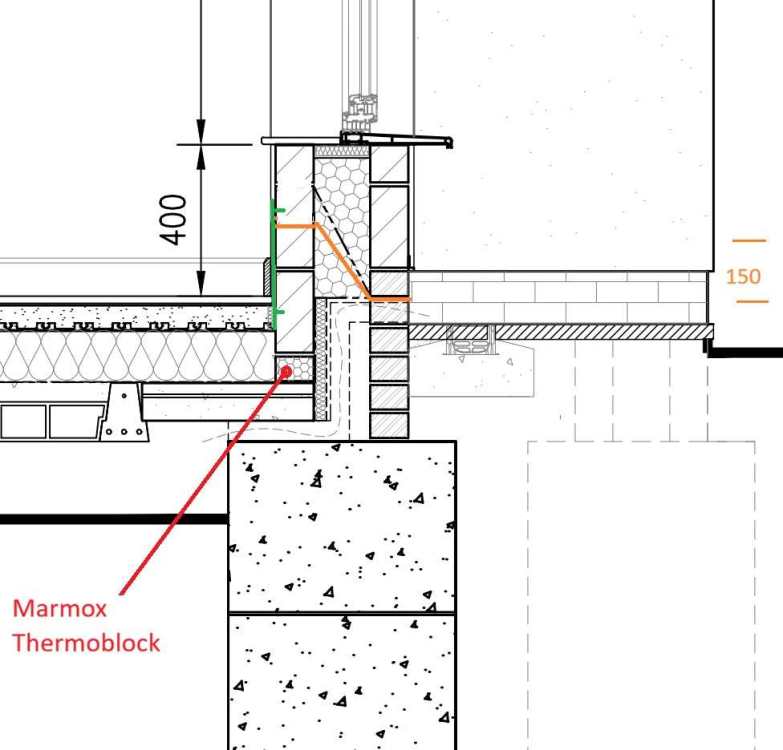

The orange 150, above, is supposed to represent the height difference across the orange tray. I've just realised the top bar is drawn a little low, & my 2 minutes, or whatever is allowed, of editing time has expired.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

I thought I'd put up a clearer picture of the poor detail @Gus Potter pointed out so that anybody who's interested can see it clearly. I'm wondering if the cavity tray went in under a full block (see orange line), this would make the arrangement sufficiently robust. We could also attach some steel brackets under the window (green line), with bolts into resin & appropriate attention to air tightness detail, behind the brackets. I've only just come up with this idea. No doubt there will be a proper way to do it, which will work better & cost less - please advise. The cill projection, at about 100mm, looks vulnerable & is much wider than I want. I've asked for this to be reduced to 45mm.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

Thanks very much for pointing out this error - I hadn't spotted that one. Although, I don't understand which bits are, "the shaped insulation". I'd expected the air brick periscopes would be drawn, hard up against the outer leaf, & I'd have more EPS beads under the cavity tray & between the periscope & inner leaf, right down to the trench blocks. As it is, there's a gap on one side of the periscope & some unspecified board on the other side. The brick sized cross section at the bottom of the inner leaf, on top of the block & beam, is a Marmox Thermoblock. Yes, it does. Thank you. Yes, it's hard for me to learn, especially with the house build being just one of several significant responsibilities I must devote time to. I am keen to learn all about this, but when I began this project, I didn't imagine I'd be forced to learn in so much detail, to mitigate the losses from people who want to rip me off & others who are just incompetent. I have already been thinking, with his limited talent, this arch tec’ is only going to be able to get us so far & unless I start again with somebody else (4th re-start) with the drawings, I’m going to need to pay somebody who knows what they’re doing to go through everything the current arch tec’ draws & re-work the details he’s not able to design properly. I know I can’t trust my arch tec’s work, because, even with my very limited understanding of what needs to be done, I can spot many errors & I can see he doesn’t fully understand how to do his job properly. Even if I start again with somebody else, there’s no guarantee the next person would be any better. I came across Richard Bendy, who may be the right person to check over the drawings. I haven’t made contact yet: https://www.thehealthyhome.uk Ideally, my arch tec’ would pay Richard to show him where he’s gone wrong, & teach him how to do what I’ve contracted him to do, but I know this won't happen. Richard Bendy's services include training architects. Re. paying professionals: I had a good meeting with a proper architect, who has designed & overseen the completion of some certified passive houses. His quote (& this is for a house that has already been designed to PP level & for which PP has been granted) was £28,272 inc VAT. This included 12 hours for electrical layouts, which my current AT’s contract doesn’t specify, & some of the things that my AT has so far failed to include in his drawings, such as door threshold detail & intermediate floor to external wall detail, were specified in the £28k+ quote. There was also a substantial fee for, “building contract admin, PD & on-site support”, which I negotiated down from the quoted fee to £2,160/month (inc VAT) for the duration of the project. I was told that it would be very unusual to proceed without this monthly fee, but if I chose to do so, I’d be completely on my own once the drawings had been handed over & I wouldn’t be able to call for help with the build (a condition arising from the architect’s insurance policies). So that’s £50k, assuming we pay the monthly fee for 10 months & don’t need any extra drawings. & this fee was based on me providing the .dwg format drawings (which I had only as .pdf) from the AT that I was about to sack, for being quite a lot worse than the current one. A prominent member on here explained, many architects overcharge for work that’s often sub-standard. He highly recommended the AT I‘m trying to work with now. This BH member gives out good advice here on BH all the time & I trusted his judgement. Here’s an excerpt from the current AT’s quote: My fee to prepare a detailed set of construction drawings for a dwelling of this scale and design, including detailed floor plans, 2 x sections, annotated elevations, site plan showing drainage and services, specific details of key elements which require further thought/ironing out such as the cantilevered box and corner glazing and a set of construction notes/specification, would be £6000 plus VAT, 50% of which would be payable upon instruction with the balance payable upon issue of final drawings. This is an all inclusive fee for the complete set of drawings and details. There are no further charges for any amendments required or liaison with structural engineers or building control, or indeed yourself. Therefore there are no nasty surprises further down the line. Thanks again, Gus. I’m away from Friday, for 9 days, so I must just explain: any comment anybody posts will be gratefully received, although I won’t respond until the week after next, because I’ll be having a fantastic time snowboarding & screen time will be limited to essential work comms only.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

Sorry - my fault. I should have quoted or namechecked you when I posted, so you'd have receive a notification.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

I might be persuaded to use something other than block cavity walls, but I’m under pressure to get my notes on how to fix the draft drawings back to the arch tec’ – under pressure from both the arch tec’ (I can put him in his place if I need to) & from my partner, who’s paying for half of all this & has become very frustrated that we’re not already much, much further forward with this project; I feel that if I take a step backwards & demand more extra time from her, for a complete structural redesign, this may lead to severe consequences. I’m also keen to get these drawings finalised soon, so we can get a BoQ/build cost, & following this, if my partner isn’t prepared to commit to spend half of whatever it might take to build this design, we’ll need a re-think. Building costs are very much higher than when this project was conceived & house values are not that much higher. I chose cavity walls because, I was told (a long time ago now) this would be the easiest & cheapest way to build. This project has been going for many years. It took forever to get PP. I designed the house before I discovered BH. The PP design has 100mm cavity walls & pre-dates the building regs change to 150mm. Obviously, my latest design has a 150mm cavity. I’ve attached the approved drawings. Since these were approved, I have persuaded my partner she really does not want a wood burner, & I’ve deleted the chimney & some of the windows. To save money & build complexity, the arch tec’ deleted the 550mm (F to C) loft space in the dormers & reduced the height of the dormers. I’ve moved some of the walls around inside, to give more space to some rooms & take it away from others; for example, there’s now more space for MVHR & other plant room gubbins (all on the left of the back door as you walk in) & less space in the adjacent room (snug). I’ve attached the approved plans. These are really poorly drawn (by me), because I had somebody helping me with construction notes, etc, back when I didn’t understand this so well; he was supposed to re-draw my rough design, but he said my drawings were good enough to use for a planning application, & we just needed to add a scale bar & a few notes. Also, I'll just mention, the construction drawings show a chunky (215mm blocks laid flat) wall next to the stairs, so I can have a floating staircase for the top flight. That's if there's any money left when we get to that stage. All the block inner walls are spec'd to go onto Marmox Thermoblocks. TonyL_NMA-ELEVATIONS.pdf TonyL_NMA-FLOOR_PLANS.pdf TonyL_ROOF_PLAN__SECTION.pdf

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

Can you not use slabs? Thanks for the suggestion, Nick. Yes, I could do, but I like EPS beads because: EPS will fit perfectly into all the awkward shaped edges, on top of cavity trays, into a badly built section of cavity that is 165mm wide (ref: one of my threads from months ago). If my trench blocks get wet, I think wet/damp EPS will be better than wet/damp mineral wool. It doesn’t have to be stored on site. It won’t get wet during installation. It won’t be installed by the brickie, who’s on a price for the job & who’s motivated to work quickly & cut corners (ie leave gaps in the insulation), so he earns himself a paid day off at the end of the job. We’ll be able to start putting the roof on sooner. Perhaps the brickie/brickies will enjoy laying the blocks & do a better job if they don’t have to faff around with fluff. The internet says EPS will be cheaper (so I’m assuming, if it costs more it won’t be loads more). The internet says EPS has a better R-value (& that will be as compared to the expertly & patiently prepared mineral wool that was lab tested to deduce its R-value). I reckon I can procure EPS installation service myself, so I won’t have to rely on the builder to deal with it, nor pay him to watch it being done, nor pay his margin. I get to choose who does the work & it will be easier for me to arrange to be there to oversee it when it happens @Iceverge likes EPS & I’m an @Iceverge superfan.

- 77 replies

-

- 1

-

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

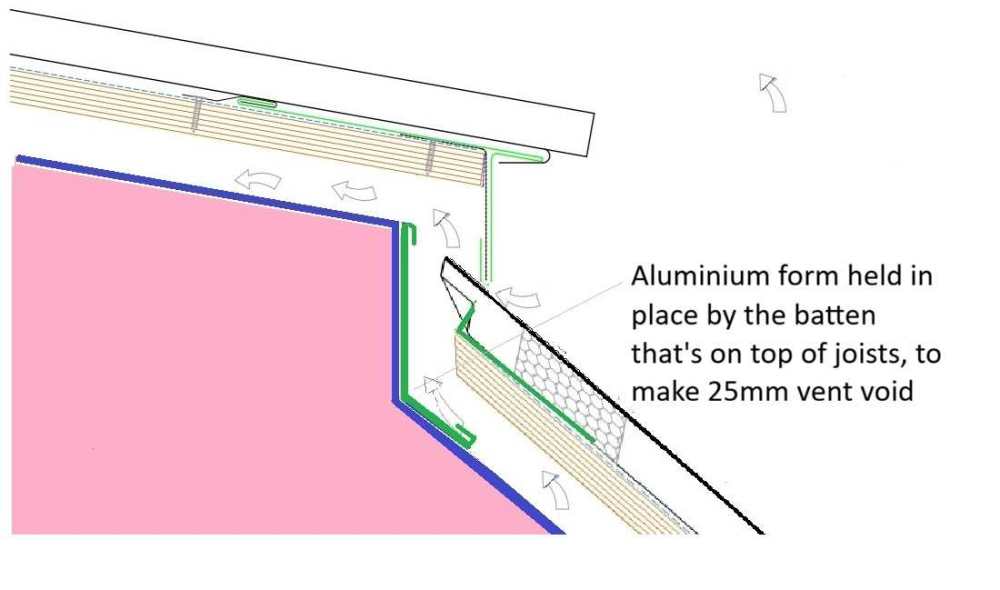

& here’s a detail for where the 3 degrees centre section meets the 42 degrees section. I’ve added in some L shaped plates (green) to prevent rain being blown up the roof & into the vent void. This same detail could be used where the the 42 degrees sections meet the backs of the 3 degrees flat roof sections over the dormers.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

I’ve added to a drawing I found online to show how the ventilation & drip edges will work at the apex of a standing seam roof, at 3 degrees .

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

I’m sorry to make the task of resolving these problems more difficult but, there is no way I’m going back for a new planning permission. I don’t want to spend time explaining the long history of how I eventually achieved PP for something that I actually wanted to build: I need to focus on what’s ahead. That's not far off what happened, yes. I don't know anything about site poured lintels. I think I ought to minimise the number of technologies I must learn about to get this house built - I'd really want to learn about it because I wouldn't trust a builder to do it properly, if he thought I didn't understand the process. My learnings about works up to DPC (mostly from BH) saved me at least £7,000 after the builder took advantage of BC's requests for changes & tried to rip me off. I like glulams too. Are these OK to stick through the inner block leaf, so they're flush with the cavity (wrapped in VCL, of course)? Sorry, I can't visualise this. Are you talking about the long inner walls that the rafter ends sit on or the gable end walls (that will have ladders going over them, for some roof overhang)?

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with: