Ben100

Members-

Posts

180 -

Joined

-

Last visited

Everything posted by Ben100

-

Cheers Rick!

-

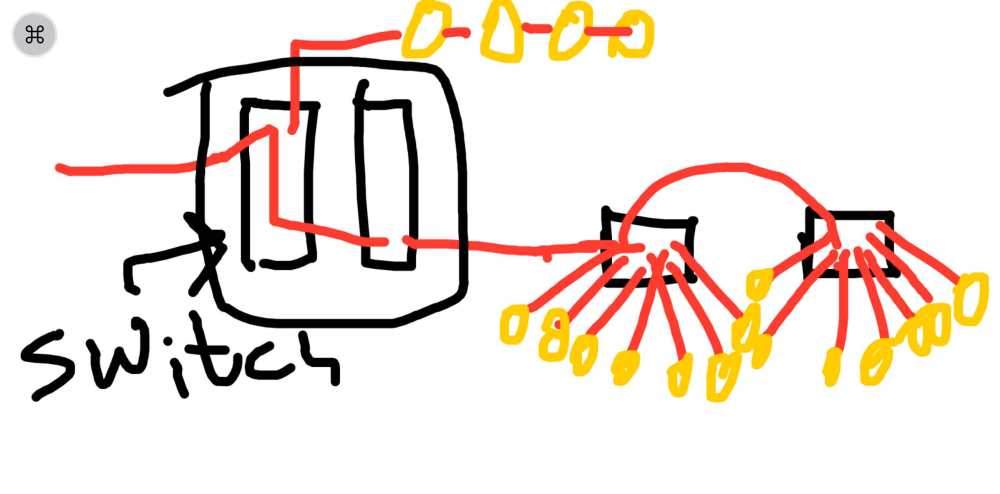

So, I’ve just checked the ‘LED’ bulbs my wife bought from Amazon, and they are not LED. Each of the is marked 40W so I’m guessing the 680W total pull is too much for the dimmer. Can I get a dimmer that can take this load or should I replace the bulbs with proper LEDs?

-

The other dimmer switch is for the side lights.

-

Yes, I connected the cluster lights live directly to the permanent live and it worked, no issues (apart from the obvious not being able to turn them off).

-

Quick update – it looks like the issue is with the dimmer switch. When the cluster pendants aren’t connected, the dimmer’s live terminal shows as live on my tester. But as soon as I connect the cluster lights (live to switched live), the tester shows it as dead. So it seems that once the dimmer is under load, it’s effectively cutting the power on the switched live. Has anyone come across this before? Could it be the dimmer not coping with the load, or possibly a compatibility issue with the bulbs?

-

Hi all, I’ve just installed two new cluster pendant lights in my lounge, but they keep cutting out. A few details: The main switch in the consumer unit doesn’t trip — it stays on fine. It’s only the cluster pendants that go off. To get them working again, I have to remove all the bulbs and put them back in one by one. Once most of the bulbs are in, or when I turn on the second circuit on the dual dimmer switch, the pendants cut out again. Setup: 2 x cluster pendants (14 bulbs in total). Bulbs are 4–5W each (so not huge power draw). Controlled by a dual dimmer switch. Other lights on the second circuit work fine, even when the pendants cut out. Could this be an issue with the dimmer switch not being able to handle the number of bulbs, even though they’re low wattage? Or is it more likely to be a wiring/compatibility issue? Thanks in advance for any advice.

-

So I guess my two options are to get a longer sill and sit it over the insulation or install it on the outer leaf of brickwork.

-

Yep. It’s on the list of jobs.

-

Yeah, I was thinking that. Maybe I need to replace the sill and sit the entire window back a little.

-

I'm planning to fill the void with foam. S it looks like the window needs to sit back a bit more.

-

Hi, I'm replacing my old bay windows and have questions about how the new ones should sit. The window sills on the new windows are shorter than the old ones, so the windows need to sit more forward on the brickwork. This is the bay window space and new window. Is the sill ok to sit like this below? And is it ok for the middle of the window (not recessed) to return to the brickwork? Or does it need to sit more like this? Thanks! Ben

-

Ok, I get what you’re suggesting, thanks. I can’t find the manifold joiners though. Where would you join the two manifolds together?

-

Hi guys, I need to add an additional 2 zones (4 runs) to my UFH. My original plumber has gone AWOL and no one else seems to want to take on the job. So it’s left down to me. Attached is a picture of what’s installed already. As you can see, there’s no more spaces left on the manifold. I do have 2 more ports left on the thermostat box though. What is the best option here? Replace the entire manifold? Add a second manifold in somewhere? Thanks for any advice guys! Ben

-

Torque requirements for power and lighting switches?

Ben100 replied to Ben100's topic in Power Circuits

Cheers guys, good information! -

Hi all, I know consumer units have torque requirements for the connection screws, but are there torque requirements for power and light switch screw connections too? Thanks, Ben

-

Hi all, I'm looking to build a new plinth wall around my new extension. The existing house (not the extension) is build with Lime Mortar. I'm not sure if I should go with Lime Mortar or a Hydralime/cement mix when building the new plinth. What are your thoughts? Cheers, Ben

-

The outlet is in that corner. I've checked, there's nothing holding it back. The membrane is above the felt. It's definitely a dip, probably around 15mm deep.

-

It does have a fall, so it shouldn’t pool. I think it’s a dip in the roof there.

-

The outlet is in the far corner, through the parapet wall. It’s still under construction, so it’s just a lead outlet at the moment. I'm not keen on the water pooling here. Maybe it can be fixed with some more layers of felt or resin?

-

Hi all, I’ve just had my new flat roof installed but water seems to be pooling in the corner by the gutter. Is this an issue or something I shouldn’t worry about? I’ve checked for any blockages but there’s nothing stopping the water going into the gutter. It just looks like there is a dip the water is collecting in.

-

I'll play it safe and fix each one, with two nails at the edges.

-

I'm using plain clay tiles, which have a batten lip, on a 30 degree pitch roof. I also live in the East of England in zone 1. If I need to pin each one I will, I just don't want to do unnecessary work Here are the tiles https://edilians.co.uk/media/productattach/t/e/technical_brochure_-_20x30_-_2020.pdf

-

Hi all, I’ve been reading about tile fixing and have found some contradictory information out there. Some are saying you just need to nail the 2 eaves rows and then every 3 or 5, while other information says you need to nail every tile. My tile manufacturer states “BS 5534 states that all interlocking tiles must be mechanically fixed.”. Does this just depend on the type of tile?

-

Yeah, after thinking it through a bit more I ended up installing an plastic eaves tray.