-

Posts

7312 -

Joined

-

Last visited

-

Days Won

38

jack last won the day on July 1 2025

jack had the most liked content!

About jack

- Currently Viewing Topic: Why we need "Net zero"

Personal Information

-

About Me

Considering a move to Octopus Energy and want to help BuildHub while getting a £50 credit for yourself? Please click here:

https://forum.buildhub.org.uk/topic/36891-considering-a-move-to-octopus-energy-and-want-to-split-a-%C2%A3100-bonus-with-buildhub -

Location

SE England

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

jack's Achievements

Advanced Member (5/5)

2.4k

Reputation

-

Just say you want to be in by Christmas, but don't specify which one. Job done. I agree with the SIPS comments by others. Do a bit of research in the relevant forum and you'll see some of the problems people have had with them.

-

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

Low points: and how to get out of them

jack replied to ToughButterCup's topic in General Self Build & DIY Discussion

We don't need more funds. When we run low, we ask for donations, and generally that gets us what we need to cover costs. All BH staff are unpaid volunteers and that won't change. "New blood" isn't needed imo, but we don't have the advantage of lifelong endeavours like farming, gardening, or photography in terms of keeping members engaged over long periods of time. Many of our members join, hang around until their build is finished, then we never see them again (obviously for some *cough* @Pocster *cough that time could be measured in decades). Over time, there'll occasionally be the need for a new mod or administrator, but we've handled that as needed. Most of the current staff have been here for many years and have no intention of going anywhere. I don't know why you think BH dropping down the rankings suggests we'd be trying to sell it. I can categorically state that there's not even the hint of a glint of an idea to sell. We have no income other than donations. I suppose someone could take over and try to monetise the site, but I don't think there's a lot of money in forums any more, plus any potential buyer would have to know that they'd lose a lot of the membership if they added advertising, sponsorship, or membership fees. I agree that the info in the site is of limited value, especially given it's publicly available to all. -

The UK has some of the highest energy prices in the world, but that's driven by regulation and how the market is structured. I doubt increased local extraction would have much, if any, of an impact on energy prices. I agree, however, that high energy prices are one of the biggest issues facing the UK at the moment, both domestically and industrially.

-

WC only sets the ASHP flow temp, and I'm pretty sure it does so using only the exterior temperature. When running perfectly, the higher flow temperature completely cancels out the increasing heat loss as it gets colder outside. Once WC is properly set up, interior temps are solely a function of whatever thermostatic feedback you implement. For example, I have a 10 year old Panasonic Aquarea. I only have the dumb controller without a thermostat. All interior temperature sensing is handled by my home automation system, which controls a relay across the relevant switched live contact. The ASHP knows literally nothing about the internal temperature of the house other than indirectly via switched calls for heat.

-

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

Observations on need for heating upstairs

jack replied to Post and beam's topic in Air Source Heat Pumps (ASHP)

Just before Christmas, we passed our 10 year anniversary in an MBC house. Overall, we're very happy with the decision to not have heating upstairs. My wife would probably prefer things a little warmer in the bedroom(!) but honestly, it's fine. Bedrooms rarely fall below about 18.5 degrees, and I have our heating system (UFH downstairs, single zone, polished concrete on insulated raft) set to come on if the upstairs temp falls below that. Currently the kitchen slab is 21.8 °C and the upstairs hall is 18.6 °C. My main regret is not putting in some form of UFH in the bathrooms. We even designed in dropped joists in the bathrooms to allow for insulation and flooring build-up, but in the end decided to save our pennies. It's not that the bathrooms are particularly cold, but the tiles feel a little chilly underfoot when upstairs is at its lowest temperatures. We ended up retrofitting IR panels to the ceilings. They help, but they're definitely not as good as UFH would be. We probably spent quite a bit more doing this than if we'd just put in electric UFH mats during first fix. If I were doing it all again, I'd definitely add UFH of some sort to the upstairs bathrooms, but would not add heating anywhere else. I would, however, consider installing air conditioning for summer. After a long run of hot days, it gets very warm upstairs. That said, I think purge ventilation could be a good alternative or complementary strategy if you don't live in a noisy area. Best to add retractible insect screens to bedroom windows so you can open them as soon as the temperature outside drops below the temperature inside, and ideally add a central openable rooflight to take avantage of stack ventilation. -

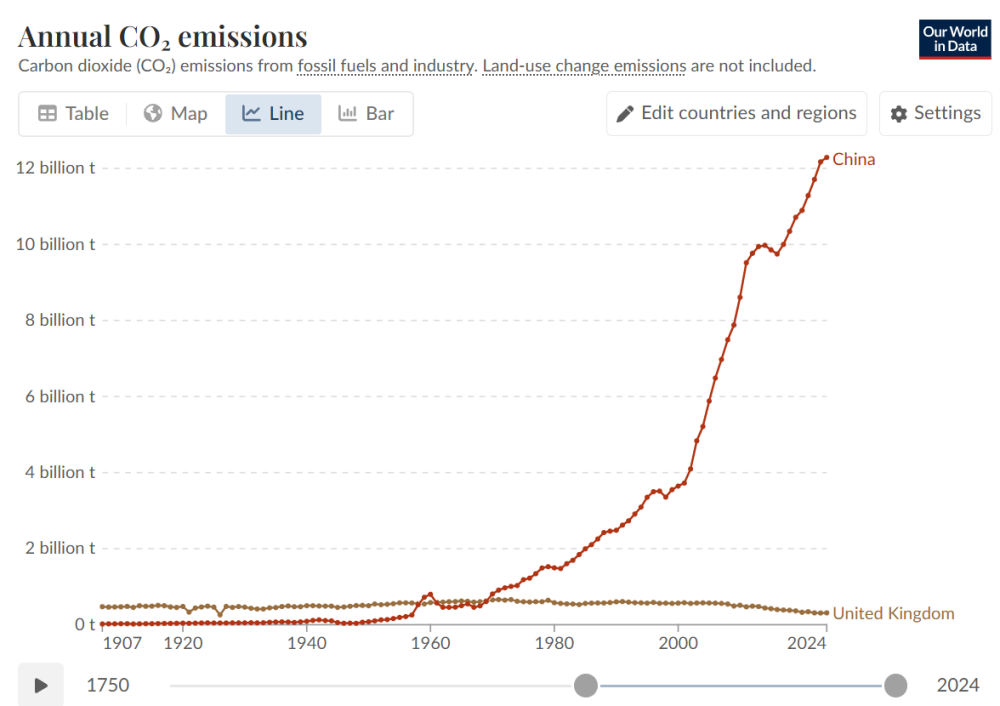

I'm not sure what you mean. We, and much of the west, exported our manufacturing (and energy/fossil fuel consumption) to China. I posted the chart to show that we're chasing net zero to our detriment while China forges ahead. What's misleading about that?

-

I didn't say they could build cheaply, I said more cheaply and quickly than the UK. How much are the two most recent UK nuclear plants costing? £40 billion each by the time they're finished?

-

100% For the most part we've just exported our dirty industries to places like China. They then got a lot better at it, provoking Jevons Paradox, and here we are: Look at the UK, saving the world with its carbon reductions.

-

HS2 was announced in 2009. It needn't take 41 years to design and build a nuclear power plant. Much of the delay is regulatory. We can do both. The UK is one of the most expensive places in the world to build nuclear power stations. I understand why it's cheap to build them in China, but there's no good reason why somewhere like Finland or France is able to build so much more cheaply and quickly than the UK. It's absolute insanity that it's no longer terminating in central London.

-

Agreed generally, but the way such subsidies work is a failure of government policy and negotiation. There's no reason for curtailment payments to wind generators to be anything like as lucrative as they are. The failure to increase grid capacity and interconnectivity is also unforgiveable. The fossil fuel industry also has the advantage of being able to avoid the costs of negative externalities. It's easy to conclude that the dead eagle at the base of a wind turbine was probably killed by the turbine. It's more or less impossible to attribute specific cases of lung cancer, emphysema, asthma, etc. to the burning of fossil fuels, but it's undoubtedly the case that it causes serious negative health impacts on human health, including huge numbers of unnecessary deaths every year. Fossil fuel extraction, transport, and use, have similar issues of their own. This is the one point I agree with wholeheartedly. Adding more renewables without dealing with the baseload required to cover periods of low renewables generation and drastically increasing storage at grid scale is completely unreasonable. Most people who want more renewables seem to not understand this. Imagine where we'd be now if government had decided to spend the HS2 money on fast-tracked nuclear power stations?

-

Most western car companies have been (pardon the analogy) asleep at the wheel. Look at the Top Gear episode from around 2012 where they visited China and ripped the piss out of what was being made over there. To be fair, much of it was dreadful, but I remember reading an article from probably that time plus or minus a couple of years where car experts opined that the Chinese wouldn't be able to replicate the complexity of existing supply chains etc in less than a couple of decades. They also said that China were too far behind in metallurgy to make good quality ICE engines. It's quite extraordinary how wrong they were. The Chinese have addressed the supply chains and metallurgy issues in short order, plus focused on EVs where the component count is much lower and the need for super high spec materials and machining is reduced in any event.

-

Nope, not me. I do look wistfully at their site every couple months. It's utterly insane how much prices have come down over the last few years.

-

100% agree, but if the OP is installing HA anyway (or already has it installed), it doesn't hurt to use it. I've intentionally kept my MVHR and heating systems completely separate. MVHR is just left to its own devices - I may eventually integrate it into my (Loxone) HA system for more flexibility around boosting times and power, but for the moment it works fine without. My heating system is kept relatively simple, in the sense that weather compensation, flow temps, etc., are all left to the ASHP, which is programmed via the ASHP controller. Calls for heat are made via the usual live switching approach. However, instead of using a thermostat to call for heat, I have my HA system control a relay. The HA system decides whether to call for heat based on the temperature upstairs, the temperature of the slab, whether the Octopus cheap rate applies, and a couple of other factors. Throughout December and early January, we had anything from 2 to 9 people staying in the house, and daytime temperatures of everything from low single digits to low teens, including long periods of sunny days and cloudy days. The slab temperature never dropped below 20, never rose above 22, and didn't change by more than about 0.8° (usually a lot less) in any 24 hour period.

- 43 replies

-

- 1

-

-

- mvhr

- ashp and dhw

-

(and 2 more)

Tagged with:

-

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

Rebuilding after demolishing question

jack replied to dustyb's topic in General Self Build & DIY Discussion

Welcome to the forum. In your situation, I'd consider insulated concrete formwork (ICF). Excellent structural and thermal performance, and good results are possible even with minimal building experience (although I'm sure it helps a lot if you're generally "handy"). Many of the big formwork suppliers run training programmes for self builders. Google search of BuildHub for 'ICF': https://www.google.com/search?q=icf+site%3Abuildhub.org.uk Personally, I'd stay away from SIPs. No-one ever posts about how great their experience was building with them, and plenty have had serious problems. -

Welcome!