Mike

Members-

Posts

1474 -

Joined

-

Last visited

-

Days Won

8

Mike last won the day on October 5 2025

Mike had the most liked content!

Personal Information

-

Location

France / UK

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Mike's Achievements

Advanced Member (5/5)

525

Reputation

-

She's right. Passive stack ventilation is driven by the difference between indoor and outdoor temperatures. In winter that difference is big so it tends to over-ventilate; in theory you could devise controls to restrict that but it wouldn't be easy. On a hot summer day the indoor-outdoor difference can be small, resulting in very little stack effect, so very little ventilation. In fact the outside temperature may exceed the internal temperature, causing the stack to operate in reverse and draw in warmer air from the top down. MVHR is a more reliable choice and offers multiple other benefits as discussed in other threads.

-

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Mike replied to fatgus's topic in Heat Insulation

Sure, you can choose to heat a Passihaus however you like without restriction. Perhaps because of that, many people in the UK seem to be unaware of the underlying principle behind why 15 kWh/m²/year was chosen (for European climates) - it's not a random number - and think that they need to pay for a conventional heating system in addition to all the other costs of achieving the standard, rather than offsetting the cost saving. Indeed it's so fundamental that it's the reason that the word 'passive' is in the name - it doesn't require traditional 'active' heating or cooling, because it can maintain a comfortable temperature largely through passive means. It's pretty useful to know on a thread discussing costs vs benefits. Worth mentioning too the innovative use of Willis Heaters as a low-cost heat source for those who do choose to add UFCH; there are multiple threads on the topic. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

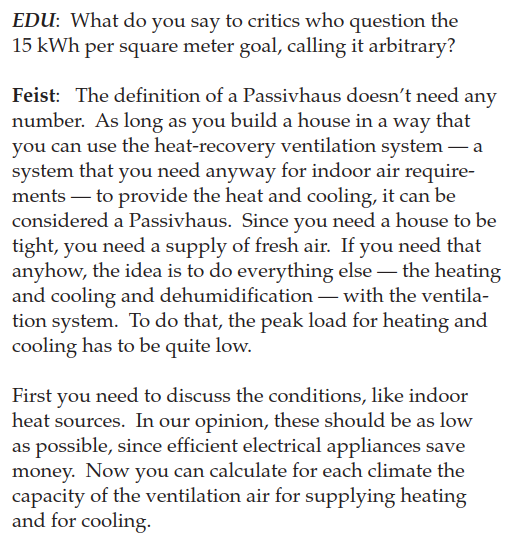

Mike replied to fatgus's topic in Heat Insulation

I evidently should have put this bit in bold: That is, when properly designed and built, a post-heater(s) on the MVHR system is sufficient to sustain an acceptable internal temperature. Wolfgang Feist, co-creater of the PassivHaus, has said that this is the fundamental definition of PassivHaus in many interviews over the years, including in this one from my archive (Energy Design Update, Vol. 28, No. I, January 2008): That's typically topped up on very cold days with a panel heater(s) or the like. In the UK at least, UFCH pipes are sometimes added for reassurance and / or for future summer cooing. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Mike replied to fatgus's topic in Heat Insulation

You may have already discounted it, but if not then you may want to consider a PassifHaus design (there are several threads on the topic). The underlying concept is that if you improve the thermal efficiency to a high level, then you no longer need a conventional heating system - and that former is paid for by the saving on the latter. That trade-off may not fully work in the UK, where the prices of certain components is higher (than in Germany & Europe more generally), but factoring in very low future heating bills (negative if you add PV) may compensate for that in your evaluation. -

If you know beforehand that they won't align, then go for an architrave back box instead, screwing the light to the plasterboard either side (though the light still needs to be big enough to hide the box); I've always used them.

-

Welcome to the forum! Your plumber is correct - Building Regulations require a minimum of 100mm concrete (above or below the floor insulation). When converting or upgrading a cellar you'll need Building Regulations approval for other elements too, including upgrading the insulation - see Part L page 60. Other aspects, such as means as escape in the event of fire, may be involved too. You'll need to raise the existing chambers to the new floor level so that the covers remain accessible. This also needs to be part of your Building Regulations Application. To avoid expensive problems, either now or when you eventually come to sell the property, I'd suggest going no further until you've found an experienced local architectural technician to help you with your plans.

-

Personally I'd run the pipes everywhere that you're not planning to screw something to the floor, other than the hall which is likely to be well enough heated as mentioned above. There is an argument for not running them under the shower tray (the water in the trap will evaporate faster) but the floor will heat up anyway - just more slowly without the loops.

-

Yes, if you're not into electronics and don't know someone who is, then monitoring is out - but if it did show a problem then it would be better to resolve it than to wait for structural damage to set in. However I'm not suggesting using it as a way of pushing the boundaries, only for curiosity or reassurance. I'm doing it for both reasons - WUFI suggests that my ceiling will be OK but, as it's a highly unusual situation and I still have a few reservations with WUFI, I want to validate it. Then option 1 on my list is probably going to suit you best, if you still want to consider IWI. That is, go to the technical department of Pro Clima or the like and ask if they'll do an evaluation for you. If you add your proposed rain screen (and it's not airtight), the chances are it will add to the drying capacity of the wall and be in your favour. Although if you can add a rain screen, maybe you can add external wall insulation, which is going to be preferable. There are many properties with cavity fill and joists embedded in the wall without problems so, if you forget the IWI and just fill the cavity, then you should be fine. However make sure that the rooms are adequately ventilated and you make the wall airtight, particularly at the joist-wall junction. At ground floor level, add plenty of ventilation to the sub-floor void (if that isn't already the case) and insulate the floor well - there are other threads on here about both.

-

From experimenting with WUFI, the place that experiences the highest humidity is (unsurprisingly) the junction of the IWI and the original wall, so ideal for a temperature-humidity sensor. There could be a moisture build-up behind a VCL (if not very intelligent), so perhaps another there. If a cavity wall has joist ends sticking into it, I'd be interested in what's happening at the cavity to joist-end junction too. You'd expect to see a build-up of moisture during the winter that declines again in spring (cold moisture is generally OK, warm moisture in contact with sensitive materials definitely isn't), without any year-to-year build-up. I've added a handful of sensors on my current project, but at various points above my very non-standard unventilated insulated ceiling, rather than for the IWI. I'm using pairs of DFRobot SHT31-F sensors & LTC4311 I2C range extenders, feeding into a Raspberry Pi via a pair of Adafruit TCA9548A mutiplexers. Until finished I'm just running occasional spot-checks: currently inside = 21.63°C & 49.8% RH, outside = 3°C & 90%, ceiling* = 10.02°C 79.53% - which is good for January, though it has been relatively mild. *above 300mm-ish of hemp insulation, no VCL, directly below timber decking + clay tiles in a very windy loft. Ubacus and similar software just shows a point-in-time, so of limited use. WUFI can throw up some very odd results too, with an incorrect internal environment. Modelling a single element in WUFI doesn't take long, so might only cost a few hundred pounds (but leaving a question mark over the output). I'd be surprised if whole-building modelling cost less than 2K. For someone doing a full-building thermal upgrade the cost would only be a fraction of the total renovation cost, so easy to justify - I can imagine some Architects insisting on it, or doing it in-house. I would guess that it's used too by Housing Associations and the like who have multiple homes to upgrade and/or their own taff to carry out the assessments. Probably not used so much by those on this forum, though there must be some.

-

Yes, those are key areas to focus on. It's a really interesting topic if you have the temperament for it; plenty of scope if you want to turn it into a PhD, or to do some DIY humidity monitoring on your eventual solution. FWIW the most extreme experiment I've come across so far is the French Réhafutur 1 project in Pecquencourt - but solid walls again, no filled cavity. They used eye-popping thicknesses of internal wall insulation, with 'intelligent' VCLs (not for the hempcrete) + very good airtightness + MVHR. Of course the documentation is virtually all in French, but I posted a bit about it a couple of years ago in this thread mainly in relation to hempcrete. The images in the linked video give some idea. Disappointingly, a long-term report doesn't seem to have been published (one day I'll get round to asking), but after year 1 it was looking positive (with higher than desirable moisture in the north-facing elevation thought to be due to moisture from the build still drying out). Tip: don't take things this far. Keep us posted.

-

As you may have gathered, what seems like a simple question is actually quite complex. Dew point is important, but dew point calculations don't take into account several key factors, such as the abilities of the particular building materials to move moisture through the structure by capillary action, nor the absorption properties of some materials (the ability to remove vapour molecules from the air and bind them within the natural fibres such as hemp and wood - not the same as absorption - before it condenses to liquid), then desorb it again. External factors are important too - hence my point about the condition and exposure of the external wall and the state of the DPC - because, as mentioned by @Gus Potter, insulating the wall changes how and when it retains and releases moisture. Then you have factors such as the presence or absence of vapour control layers, vapour permeable paints and MVHR... Anyway, to answer your question, I can only think of 4 ways of deciding on an insulation thickness: 1. Major manufacturers of vapour control layers will run it through their model and come up with a recommendation based, of course, on using their VCL, which must be installed to very exacting standards. You'd be wise to include a service void with a VCL to cut the risk of damaging it (now or in the future). 2. Find a consultant to carry out a WUFI analysis. However WUFI is highly dependent on the data used for the building's internal environment (variations in temperature and humidity throughout the year); the default data options provided are very finger-in-the-air and don't take into account factors such as the presence of MVHR, which can significantly cut moisture levels. That situation can be improved by using their companion software to model the environment of the specific building as a whole, but that's going to rack up the cost significantly. I'm not entirely confident in the standard external environment files used either, in view of the expected climatic changes, though at least those are more easily assessed and changed and have less impact on the output. 3. Take a cue from research such as that carried out by Historic Scotland. If only there were more of it available to cover a greater range of buildings and locations. 4. Go no lower than the more-or-less accepted 'safe' U-value limit of 0.5W/m².K

-

premature posting - hang on...

-

Yes, I was using the same version in 2008 and had a similar experience with the climate data, though I don't recall trying anything as exotic as Vlissingen! At the time I didn't think about getting data for the future climate; nobody then was expecting much of an impact from climate change this century, at least not among the general public. And the forecast data probably wouldn't have been available anyway.

-

This was something the Danes realised decades ago, at least for wind turbines. Their introduction, back in the 70s & 80s, was partly driven by local energy co-operatives, allowing local citizens to invest in and profit from their local wind turbine(s). I just went looking for some stats and, from here, in 2016, more than half of Denmark’s installed wind capacity was owned by citizens, rather than private companies. That's a lot of citizen involvement in a country where nearly 60% of electricity generation comes from wind power. There are similar schemes in France, allowing local citizens to invest and profit from local solar farms.

-

From a mention of GB0013a-Hemsby here, this is historic data, not forecast data (which likely also means that they're based on an average year, not a heatwave year). It looks like PHPP 10.6 included updated climate files, but can't spot anything about how they changed. Your PHPP manual may say something about using .epw files. They seem to have become something of a standard, so I'd hope that they could be easily used now. As opposed to the climate data sheet in my PHPP, which just says 'To enter new data, fill in yellow cells'! Alternatively, it looks like Meteonorm sells PHPP-ready future climate files.