Search the Community

Showing results for tags 'steel beam'.

-

On Monday the second gable is poured and most of the internal bracing, corner bracing and window shuttering is removed. Tuesday rains all day so no work on site. The internal floor is under 1 inch of water with no way to escape, without us brushing it towards soil pipe. Good to know we are airtight at the floor/wall joint. The steels are installed, we were supposed to have wooden roof beams but somehow this was not calculated by the architect who insisted the roof truss company would do the calculations later. The roof truss companys only want to do the calculations when they know you are ready to order and they said the beam spans could not be done. So on the last minute we had to go back to the SE who worked out our steel beams and the total cost of roof went up £8k. I wish the architect had suggested the SE looks at the roof calculations earlier but unfortunately we just have to move on from this, and up to this point we have had no other extra costs. Since we are no longer working with the architect I have had to find a new SAP assessor who I can engage with as the build progresses. We have been discussing how changing the steel beam might change things as the vaulted ceiling can now be higher if we want. This gives us more space to heat up. I also wanted to know the effect of not putting as much solar on the roof or not having the wood burner changes the SAP results. Since having a smart meter fitted at home we have reviewed our current electric usage and decided that less solar (7.5 kwp instead of 11 kwp) but with the ability to add a battery. Also I think aesthetically one row of 15 panels will look better. Total Man days of labour week 7 is 16 days. Total to date b/f £44925 New Design Stage SAP Calculations (previously done by architect) with ongoing advice about changes that will affect the SAP and to include the As Built SAP documents and EPC at completion £720. It does seem a lot compared to online prices but for peace of mind knowing that we can if we choose to only put 6kwp of PV on the roof instead of 11kwp, is an overall saving. Total to date £45645

-

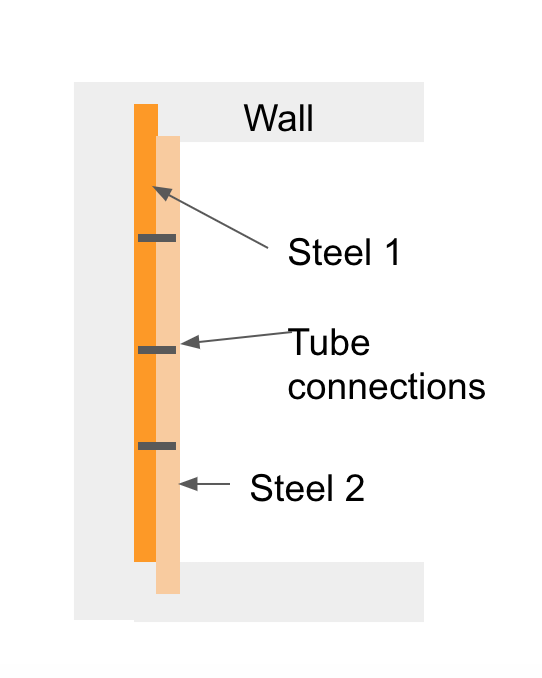

I am installing a twin steel beam to support a chimney stack. The beams are 125mm too short. I'd rather not order new beams as these were very expensive and massively over engineered for the job. My private building control inspector has informed me that I can offset the two steels to gain 125mm and connect them with 3 tube connections. Can anyone confirm that this is right and safe? Sketch attached The alternative would be to add a splice but this would cost around £300 and again seems like overkill. Thanks very much

-

Hi All My first post - so a bit of a rookie! I am designing a flat roof back and side extension to my Victorian Terrace and I want to expose the wooden joists of the flat roof into the exposed steel beam (like in attached pictures) I am trying to work out how these are fixed into the beam which is a UC 254x254 - obvi the traditional approach would be pack with timber + hangers but as it will all be exposed Id like a more aesthetic solution. As far as I can tell, I need a 'nice' looking hanger to fit inside of the beam that can be painted with intumescent paint along with the beam and am looking for recommendations for these. Or, do steel companies design this into the beam as it looks like in some of the pictures? I did email one to ask but the answer was no. Any recommendations for these as well! Thank you in advance.

- 3 replies

-

- joist hangers

- joists

-

(and 1 more)

Tagged with:

-

Hi After closing our site up in December due to the weather, we are trying to get back up and running. We have poured the raft foundation and built the retaining walls which also form the basement. There is a beam and block floor sat on top of the retaining walls. This forms a new kitchen floor, and also an outside terrace. Between them I need to start building a cavity wall with 150mm cavity off a pair of UC beams, which have carried some of the B+B concrete beams. How can i reduce the thermal bridging, and also close the cavity? Could I bridge the cavity with some PIR and build off that, or is it likely to compress too much. The basement room below is a store/workshop. The block wall is only two courses high to form an opening for a 2.6m wide sliding door onto the terrace.

- 5 replies

-

- steel beam

- thermal bridge

-

(and 1 more)

Tagged with:

-

Anybody have an opinion on this method fixing posi-joists to steel? I thought I would have to use a packer in the flange of the steel but seems not.

- 5 replies

-

- posi-joists

- steel beam

-

(and 1 more)

Tagged with: