Search the Community

Showing results for tags 'framing'.

-

How do I tile around a inset/drop-in bath

Donegalsd posted a topic in Bathrooms, Ensuites & Wetrooms

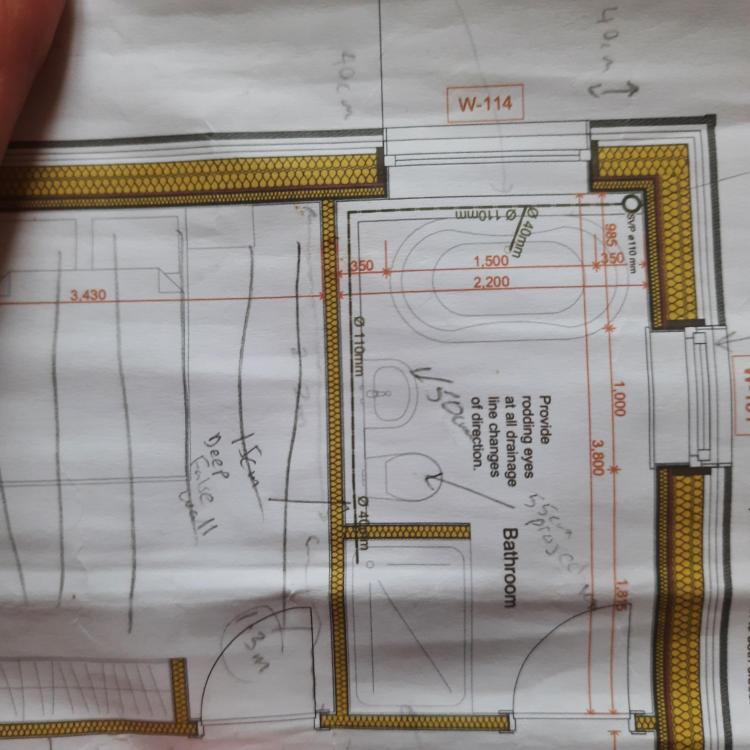

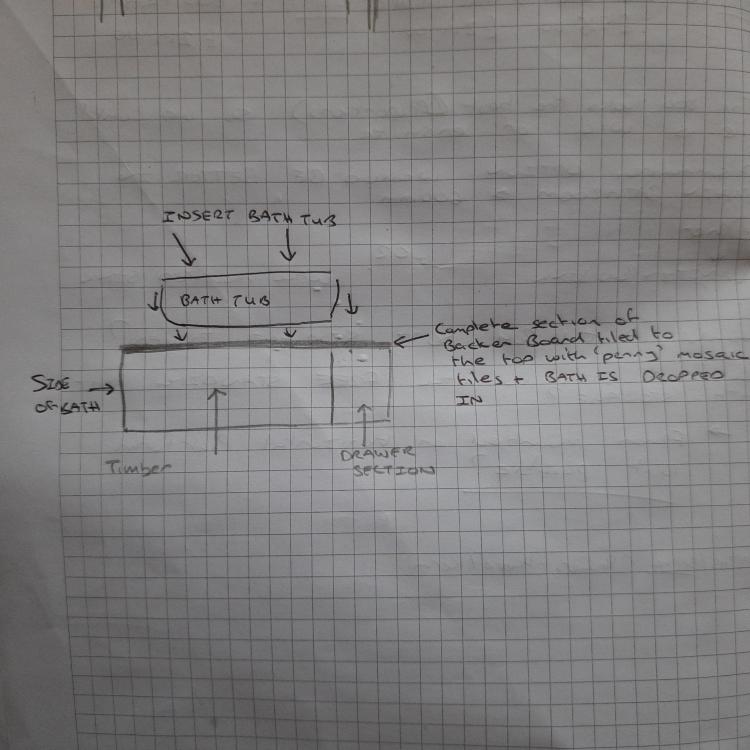

Hi, I would like to fit an oval bath probably this one, https://www.megabad.com/hersteller-koralle-badewannen-serie-t200-ovalbadewanne-a-100501.htm Into a frame in my master bathroom. I am thinking of using a timber panel on the side of the bath and hopefully I can get a joiner to make a storage drawer to pull out at the foot of the bath. The timber bath panel and the drawer face may be fluted so the drawer is 'hidden'.Pic and diagram attached. But how do I deal with the top of the frame. I was thinking, if I support the tub from below, I can cut a hole in backer board, drop the tub in, tape the backer board to the bottom of the bath rim and then tile with mosaic tiles all around the rim of the bath - over the top of the tape. Does this make any sense and will it be watertight? I won't be doing any of this myself but I want to find if the proposal is feasible. Thanks -

I suspect not, because simple framing screws (i.e screws not intended for use in concrete) don't have groove in the thread do they? Like this These are the ones for concrete aren't they? (apologies for the blatant copyright rip off) Yet there are plenty of adverts for screws to go into concrete that don't have the grooved thread. These for example are advertised as '... High quality Concrete Anchor External Screws that cuts its own thread directly into pre-drilled 6mm pilot hole, no anchor or plug is needed. Masonry screws are an excellent way to fasten any material to masonry...' I need some hefty Torx concrete screws (M10, 120mm) to fix my wallplate (for the first floor) to the wall. Please would you help Confused of Lancaster?

- 17 replies

-

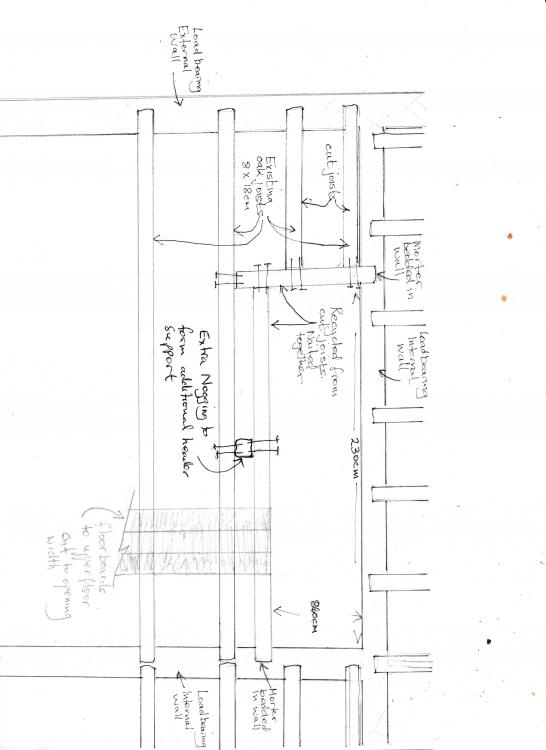

Hello everybody, Here's hoping there is someone who can help with this.... I am converting the loft in my old house that has exposed beam (joists) ceilings. I need to make a stairwell opening. I do not want to use joist hangers or brackets as these will be visible. The joists are 3x8 inch (8x18cm) oak joists in very good condition, no worm or rot at all. The span is 4M and joists are at 52cm. I hope you can see my sketch. My plan is to support and cut back 2 joists to form the opening. To reuse one to form the header and the other the length of the opening, to reduce the opening width. I do not have the space upstairs to have the wider opening to the next full length joist. Please could I have you advice on this plan and will nailing these be adequate? I hope that makes some sort of sense...... thanks for looking.

-

At the moment I am using two different nail guns: a Hitachi gas gun for framing, and a Clarke coil nailer that runs off a compressor and fires full head nails up to 70mm. initial impressions are that the gas nailer is handier in many ways, no hose to drag around behind you, but overall I don't think it's any faster to use as it has more issues with jams, cold gas, and of course needs reloaded more frequently. I have been surprised by how temperamental it can be below about ten degrees celsius. The coil gun has the option of sequential firing which can make scarily rapid progress on things like sheathing. Even running it off a cheap little 12l compressor it is faster than I am. The main thing that drove me to get the coil nailer was that I was able to buy stainless full head nails for a fraction of the price of the Paslode-type ones for the gas gun. I will need these for my timber cladding and the relatively cheap coil nailer has probably already paid for itself just through the difference in cost of the nails. Plus, no more taking out fuel cells and sticking them in your armpit until they are warm enough to work!