Search the Community

Showing results for tags 'central heating'.

-

Hi All, We have recently bought a newly built "dolly house" which is equipped with an Ideal Combi ESP1 35 boiler with 2 zones (upstairs and downstairs) managed by Honeywell T6R wireless thermostats. I have been looking into heating controls for friend and got around to the learning a bit about OpenTherm and weather compensation. Then it dawned on me to check my own CH system and I was not entirely surprised to find that although both my boiler and thermostats support OpenTherm it wasn't being used! Clearly the plumbers weren't ready to embrace the new technology. I then learned that my boiler also has the option of weather comp too and this got me thinking. As it would cost very little and take minimal effort to modify my system to use either OpenTherm or weather comp would one have any significant benefits over the other? If it were your house which would you choose? The Honeywell control box is right next to the boiler so running a cable for OpenTherm would be a doddle and I can easily run a cable from the boiler to a north-facing wall for a temperature sensor for weather comp so either way would take no more than 30 minutes work.

- 18 replies

-

- central heating

- weather comp

-

(and 2 more)

Tagged with:

-

Anyone using VDI 2035 spec for heating water in an ASHP. Been looking at it seems a smart way to go. No chemicals to turn into a muddy soup, good heat transfer etc. Monitor with a simple conductivity meter and pH meter to control to quality of the water going into and in the heating system By monitoring Conductivity (80 to 1550 microsiemens) Ph 8.2 to 10 And Scale products below 300ppm Any one using are there issues? What if any fitters are you using Do you top up via an Ion exchanger or just tap water (of suitable quality)?

- 26 replies

-

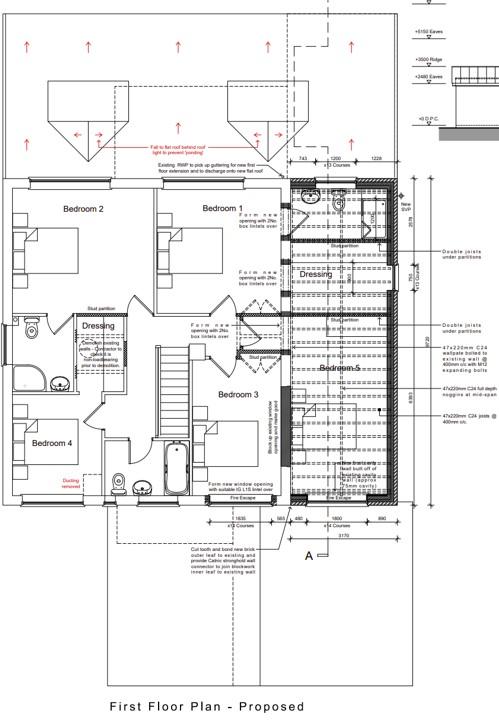

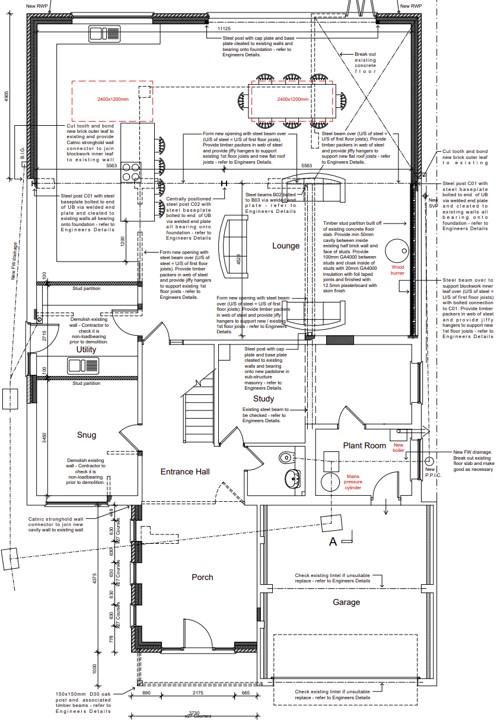

Afternoon all, I've been browsing the forums for a while, messaged a few users direct but as we are fast approaching water tight I'm after a steer from the group on all things plumbing...... Attached are a couple of pictures of what will be the finished ground and first floor plans. The existing house is/was heated using a warm air boiler (located in what will become a snug) ducting through floor to ground floor rooms and into the loft and into 1st floor via ceilings. hot water was previously provided by an electric hot water cylinder (i know $$$) located on the first floor. (Cold Water tank in the loft) Mains gas and water come into the house in the snug (it used to be the kitchen). The intention is to re-route the mains water/gas to a plant room accessed off the garage which will house new System Boiler Unvented Cylinder Water Softener Heating will be provided by radiators in bedrooms, snug, study (8 Rads) towel radiators in bathrooms/ensuite (4 Rads) underfloor heating in open plan kitchen/living room and porch This will be a completely new plumbing system with all existing plumbing decommissioned as the job goes on as we are still living in the house as while work progresses. The first floor joists run side to side (across the front) of the house, except the rear extension which runs front to back. Up until last week I was intent on using a branch/tee plumbing system for the hot water and central heating (because that's what I was familiar with) but I then realised how much more common the manifold systems have become. I've plumbed in plastic before when renovating our last house and I like the idea of using a manifold system because it gives a continuous run of pipe to the appliance/rad (reducing scope for leaky fittings at junctions/turns etc) but I also note the issues with having to empty fairly long sections of pipe before it receives hot water, to give an idea of scale the house is about 12m wide 14m deep. In terms of design my questions to you lovely people would be, should I Use one manifold in the plant room to serve CH pipe runs to all rads and towel rails and secondary manifolds serving the UFH? In respect of DHW and CW run a feed to each bathroom and install a manifold in each bathroom (therefore a using a shower means a significantly shorter length of pipe needs to be vacated for the sink hot tap)? Is running a manifold off another manifold a no, no in terms of maintaining consistent water pressure etc? In terms of manifolds etc, I'm familiar with 15mm, 22mm etc. but I'm seeing reference to 10mm, 16mm across some brands. Is there a preferred brand of pipe, manifold etc. you would recommend? I'll probably have more questions as we go on but I am actively scouting threads looking for answers etc. so thank you in advance for all the contributions

-

- renovation

- manifolds

- (and 10 more)

-

My Honeywell CM907 controller has finally died (LCD screen). Can anyone recommend a good replacement option? I still have to decide whether I want a wired and fixed controller, or a wired base and WiFi controller. It is gas fired with ufh. Thanks Ferdinand

-

Latest https://www.thetimes.co.uk/article/villagers-are-first-to-burn-hydrogen-but-dont-notice-p7mr8gp27 Who knew!