-

Posts

1053 -

Joined

-

Last visited

-

Days Won

5

craig last won the day on January 5

craig had the most liked content!

About craig

- Birthday 05/27/1977

Personal Information

-

About Me

I'm a self employed window and door specialist and have 15+ years experience in the Passive House and Low energy windows and doors.

I’m also supplying consultancy services and can help you in obtaining prices and take the stress away from you.

Happy to help in anyway that I can, drop me a message if you have any questions. -

Location

Fife

Recent Profile Visitors

craig's Achievements

Advanced Member (5/5)

435

Reputation

-

sliding door threshold detail with external wall insulation?

craig replied to Ed_'s topic in Doors & Door Frames

That detail for the sliding door sitting on compacfoam over the insulation and partly over the concrete slab isn't substantial enough, I'd be concerned with the point load over time and potential operational issues occurring. Sliding doors need a solid base to sit on over the entire depth and needs to be level. It can sit on structural insulation but it needs to be done right, part of it is sitting on insulation and that's asking for problems. How's the threshold being fixed in place, how is it be packed (if needed)? -

Week 40 - We’ve moved in!

craig commented on Benpointer's blog entry in Contemporary build in north Dorset

Congrats, was a pleasure meeting you and your wife and it is a lovely property. You have done very well.- 14 comments

-

- 1

-

-

- moving in

- airtightness

-

(and 3 more)

Tagged with:

-

Gas is gone within 15/20 years, it doesn’t massively impact the performance.

-

It's not that uncommon to be honest, even the larger suppliers will only give approx. 2 years on parts, 5 years on glass and is about standard in all honesty. I'm not shocked at those. Manufacturers can only give the warranty for the periods the parts from the suppliers are warrantied to them for. The actual window construction (corner joints, lamination, etc. will be a longer 15/25 year period). It's really unfortunate that the glass has failed, it happens, it's a pain (excuse the pun) in the a**e but I wouldn't be blaming Nordvest on this occasion. As long as the complaint is accepted and a new glass unit supplied but that is down to the glass manufacturer and they have stringent rules they follow for this. I'm presuming the installer and son were German? If yes, they know their stuff, I've known them for years.

-

Wet work (screed) can cause the lacquer to react and it looks like the finish is compromised. It does settle back down but primarily it can cause swelling to the timber. Which is why it is better to wait until that is done. As for the vents, that’s BS. It depends on the type of vent used and which way they are facing. I would suggest that they are cheap vents.

-

High probabilty of a failed glazing unit, unfortunately this happens but should be covered by warranty. Do you mind me asking system/supplier? Glazing can be anywhere between 1 ((ulikely, usually minimum is 5) to 10 year warranty. It’s down to the warranty the manufacturer receives from the glass supplier. Just like hardware (handles for example) it is down to what the supplier of the hardware supplies as to the manufacturers warranty. You should be covered though for new glass unit.

-

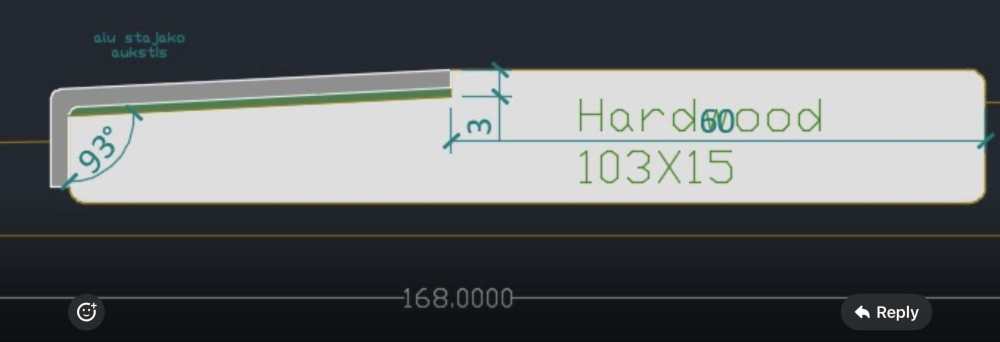

Norrsken patio doors with slide under sill

craig replied to Selfbuildsarah's topic in Windows & Glazing

They are fine, 3mm is substantial enough but I personally prefer them having something solid underneath and non slip. All they will do is put that down and then sit the door on top. Make sure they seal along the length before sitting door on top to stop water penetrating further back. -

Norrsken patio doors with slide under sill

craig replied to Selfbuildsarah's topic in Windows & Glazing

It’s effectively a tray as the threshold doesn’t tend to go all the way out, thresholds are generally the depth of the door frame. something mire substantial would be a 20/30 height timber and wrapped in aluminium. Something like this but you either sit the door on top ir recess the timber to make it as flush as possible. The aluminium can wrap underneath and back if required. Usually you have to have this made. You can ask them to make it for you. -

Norrsken patio doors with slide under sill

craig replied to Selfbuildsarah's topic in Windows & Glazing

Are you meaning like a tray that sits under the door to prevent water going further back under the threshold of the door, or standard threshold/extended threshold that projects further out? Is it an entrance/side door, lift and slide, French door (inward/outward)? -

Have you bought it? I have about 20 metres of ME508 available (100mm depth).

-

Norrsken patio doors with slide under sill

craig replied to Selfbuildsarah's topic in Windows & Glazing

What is your external reveal finish? Brick, render, cladding or a mixture? Cills/Sills are pretty straight forward, minimum 20mm overhang but recommended overhang is 30mm and a max of 50mm. From the known window position count from the front face to the external finish, then add 30mm for the minimum overhang. Then add 16mm from front facing of aluminium, to the face of the timber of the window and an additional 8mm for the rebate in the frame (check this is correct with Norrsken about the 8mm). The rebate will sit back a further 8mm (maybe more, but 8/10mm is standard). Sills are always the same width as the window, unless specifically requested otherwise. Now choose the right end cap, they will likely offer 2, straight up (brick), straight up and over (render/cladding). Make sure they supply the right one. -

Norrsken patio doors with slide under sill

craig replied to Selfbuildsarah's topic in Windows & Glazing

If you want any assistance, let me know. I’d be happy to have a look over it for you. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

craig replied to fatgus's topic in Heat Insulation

I’m heading to Chard today, so there’s a possibility that could happen lol An example, Aluplast Ideal 8000 has an air permeability test result of class 4. Which equates to following under EN 12207 Class 0: no performance determined Class 1 → Class 4: increasing tightness levels Class 4 = best performance — minimal air leakage under up to ~600 Pa pressure. EN12208 watertightness, class 9a -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

craig replied to fatgus's topic in Heat Insulation

They are uPVC systems 😉 -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

craig replied to fatgus's topic in Heat Insulation

Yes, the likes of Internorm, Aluplast, Gealean, Kommerling, Dako, Rehau etc. have air permeability test results according to EN 12207.