daunker

Members-

Posts

70 -

Joined

-

Last visited

Everything posted by daunker

-

Only just seen this! Sounds awesome, did you/your wife complete it, any photos? If that's all the metal costs, I'm definitely up for taking on the challenge. I've actually got a zinc roof on and I think he does copper roofs... So I'll find out. Sorry just seen her Etsy those look awesome..!! Very happy with a DIY effort if I can make it, if getting it on the door is the easy bit then I'm going for it. Doesn't matter if it's rustic or chaotic I don't really mind too much how it looks. Fingers crossed!

-

No worries my man, I have a door sized opening still with nothing in it myself. What did you go for? I have a pal whose helping me and can make me an oak one, might just see if he'd be up for trying a metal one..

-

@Tony K how did you get on with this in the end? Did you have a shot at it?

-

So... Inspired by this thread I bought the reliance manifolds from Screwfix. I just laid the 5 feeds to each bathroom. Tomorrow I'm going to connect them to manifold. I have 5 hot and 9 cold (including kitchen sink and kitchen appliances). The pipe I bought was the hep20, and to be honest I presumed the reliance manifolds would be fit for anything, but as per above when the box came it says John Guest on it. Which has made me nervous but 15mm barrier pipe is 15mm barrier right? @Nickfromwales kindly suggested 15mm copper tails to separate manufacturers, but I am minded to only do this where I'm stepping from 15-10mm. Has anyone above uses hep20 with it and it was ok? Next q. When mounting manifold I have a tall wall and I'm wondering if I can mount manifold ala ufh manifold ie the hot sits proud in front of the cold. It would save me some horizontal space and also save pipes crossing each other as they come up from the slab. Fingers crossed. Thanks! Will share photo when complete, I'm on it tomorrow!

-

That makes sense, they are fixed with straps on purlins but the spacings are 600mm, so intermediate or where light fitting goes and cable dangles they had used tape.

-

Thanks both so appreciate the replies.

-

Thanks so much @nod, Sparkie said for me to just pull cables through. And I thought I could then pb the lot. Sounds like I was about to get unstuck. By pattress do you mean ply or something else above the pb for each fitting to screw into and distribute weight of light fitting/smoke? Id rather assumed (sounds like incorrectly!) could just fix to PB as would only be lightweight

-

Thought cables aren't allowed to go with insulation surrounding them? There is another 215mm rockwool insulation between purlins. Lights are surface mounted spots to avoid having to chase out the celotex. There is not an additional VCL. I'm sure I'd read @nod say elsewhere he didn't particularly like VCL on ceilings as when he was taking old ones down was moisture? Was some months ago so can't remember detail. The celotex is foil faced both sides and 50mm so I don't see it's that heavily compromised as VCL. I'll pop some gaffa tape up instead. Thanks for input

-

I've 50mm celotex below purlins and then resilient bars running perpendicular over top. First fix electrics going in, and boarding this week. Electricians used some aluminium insulation tape to pin cables up (and some straps where were joists). The insulation tape has let cables dropped, is it literally just to hold them up temporarily until PB is fixed, and then cables at future point drop onto pb as tape fails or should I attach a little better with something. I did half wonder about those insulation clips for ufh pipes. But if only needs to hold extremely temporarily until PB is fixed I'll just pop a bit more tape on. Will ask electricians too but wasn't here when they were working, and would value a second opinion. Thanks!

-

Lovely thanks team great news. Exactly what I was hoping to hear. Will look up fitting and manifold instructions in due course but for now will run the five pipes per bathroom, or four I guess if the basin/toilet unit splits the feed which it may do?

-

I'm converting a building, concrete slab. Then dpm then 150mm PIR in two layers then ufh pipes and 50mm liquid screed. The building is single storey has two bathrooms and kitchen. I'm doing as much as I can myself to save costs. I have read with interest about the hep2O on here and simplicity of it (sounds great). Easiest solution to me seems to run the water supply between insulation layers, probably channeling out the run, (or possibly as is 75mm insulation i could make the small portion of the top layer 25mm+50mm insulation, and run at least the cold supplies side by side. Is this the norm to run in the insulation layer below screed, seems v straightforward hopefully? I hope I wouldn't need it in conduit but maybe? Then leave long tails up in broadly in the location, but certainly where the stud soleplate will go. I have been inspired by here to have manifold and individual supplies for each so no intermediate joints/connections. Most on here are going round perimeters drilling timber studs but I have door ways and limited height so has to go underfloor or be incredibly circuitous and sharper angles?

-

Cavity external doorways- returning blocks inside to out?

daunker replied to daunker's topic in Brick & Block

852x2200mm 'element weight" 89kg Internally will be 150mm PIR then 50mm liquid screed with ufh pipes. So that's the sort of makeup I have hence the course of blocks height, although it's slightly above my ffl. What do you reckon would be best? Door has 25mm threshold so fairly flush with finished floor. Was planning to put a strip of 50mm PIR on the outer face of the course of blocks maybe 10cm high and fix in mortar join as well thought that would help and overlap with the height of internal screed. Ok it wouldnt be taped to the pir on timberframe but it would hopefully help as an additional thermal break to the 25mm upstand internally. Sorry I'm getting sidetracked here. Really appreciate getting feedback from my own project where I just deal with my own voice in head. Thank you. Really value any input -

Cavity external doorways- returning blocks inside to out?

daunker replied to daunker's topic in Brick & Block

That's good to hear @Iceverge . Most fit the pir to the inside and it did make me worry a bit. All of a sudden the breather membrane isn't going to do much breathing with celotex fixed and taped to outside, but I liked not having it internally. So the timberframe soleplate is going to sit on the block and I've preconstructed it, because having to build back to front. Made panels bit big really should have done smaller for the lift. But be good when they're up. See photo. @Faz that's encouraging but the inner course of blocks is going to run whole way around I think? I just left those blocks off as wasn't sure what to do. I was thinking of maybe getting a couple of marmox to sit in the opening and for the door to be sat on. I think the door requires solid underneath. Was wondering about concrete. There will be 25mm PIR upstand internally to the blockwork for screedng up to. Around window openings I am just going to have timber closing cavity. Ive used the plastic ones with foam before, but I'm really not convinced in real world situation they are very good, very hard to seal. Will be dpc on the face of it and then screwed to frame. This is because velfac windows sit on finished render. I was probably thinking the same of the door opening. Windows will be on straps so back overlaps with the insulation and front is sealed against (but not fixed to) the block. Was kind of thinking doing same with the door? Nb a lot more fixings for pir now. I used a mix of zinc washers and plastic ones I had left over mostly used the plastic ones for joins as they are quite oversized. Wasn't really sure which was best so hopefully a mix will work. 2.4m high and 400m stud spacing 3/4 per stud -

Cavity external doorways- returning blocks inside to out?

daunker replied to daunker's topic in Brick & Block

Ok so heres a photo. Single course of 140mm blocks timberframe to sit on top. Finished floor level is a little below block height, will be a 25mm celotex upstand internally and 150mm insulation then 50mm liquid screed with ufh pipes in it. Timber frame is 145mm with rockwool between studs then going out 11mm osb, breather membrane, 50mm PIR then 25mm ventilated cavity. I was going to also run a say 10m strip of 50mm PIR externally on inner course of blocks. Is returning blocks like this a normal design, feels a little cold Bridge-y? -

Treatment plant inlet T below water line internally

daunker replied to daunker's topic in Waste & Sewerage

-

Just concreted in treatment plant (marsh), and looked inside. The inlet T is below the waterline. It's filled with water and flows between chamber and to outlet fine. But I was just curious about this. Is this how it should be possibly to airlock/gases(?) In my head I was concerned about anything coming down having to be pushed down into the liquid below or it could cause a backup. Ok most stuff should sink, but was just not sure. Thanks!

-

I'm doing a conversion with existing blockwork. There are two openings for doorways, one ive cut and the other was always open. Internally there is a course of 140mm block that I am laying fresh and then will be dpc and timberframe sit upon this. Outside to in will be render, 140mm block, 25mm ventilated cavity, 50mm PIR, 11mm osb then 145mm timber frame 11mm osb inside and plasterboard. Rockwool between studs. My question is, friend has said on the other opening (no existing external course of blocks) I should return blockwork from inside to out, and on this one I should have returned it. As I haven't I should infill (with concrete). Is this right? Is there another way. I kind of presumed I would just get those cavity closers, I am mainly concerned about cold bridging, but also want to do it right! I'll be running the celotex on outside of timberframe 'long' so that it overlaps the top half of the block, to give some insulation and inside I have insulation and then screed with ufh so again will have a strip of pir around perimeter. I was wondering if I should get some marmox thermoblock just for these openings. I could afford to do a course around the whole building hence using the blocks I have. Fingers crossed someone knows and thanks!

-

Window Position and Fixing in Stone Clad Timber Frame

daunker replied to James1234's topic in Windows & Glazing

Yeah so mine is a single storey so only like 3mm differential. The tolerance is 12-15mm and sealed with that expanding tape you refer (keep cool before use). It's what velfac recommend. So I think it'd be grand. Just surprised no one suggested it above? -

Window Position and Fixing in Stone Clad Timber Frame

daunker replied to James1234's topic in Windows & Glazing

Sorry to bring up an old thread, but I am positioning my windows. And having similar dilemas. Why wouldn't you pull the windows say 30-40mm forward in the first post such that they can be sealed against the stone, but still are fixed on brackets to the timber. The window depth would still overlap the cavity and timber frame and insulation. A compromise but insulation would still overlap so not a horrendous cold bridge. It's what I was planning to do so surprised no one suggested or is there a reason I'm missing? -

Was reading on here into the small hours, and thinking why don't I put the 50mm celotex on the outside of timber frame rather than the inside. Ie: existing Block, 25mm ventilation gap, 50mm celotex, breather membrane, 12mm ply, 140m timber frame with frametherm, ply, vcl, plasterboard. Could then insulate the soleplate externally and also the entire Frame? Is there a reason more don't do this?

-

Lovely thank you, I drilled and chemfixed previously which worked well so will repeat that then 👍🙂

-

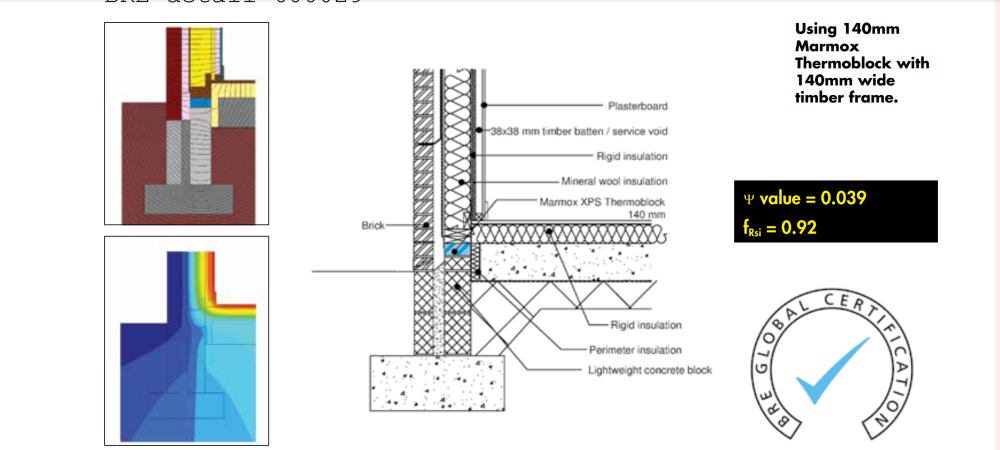

I'm doing a conversion and building timber frame inside existing 140 dense blockwork building I've read about problems with condensation on soleplate occuring. What is the standard block below soleplate. I had been hoping to use thermalite or equivalent. I looked up marmox thermoblock, and they have detail below. Whilst I can see there is advantage to having it below soleplate it doesn't mitigate the cold hitting the front face of the soleplate. I had thought that air temperature on this face might be more prone to dropping below the dew point and does this not have same condensation risk as from below? If condensation is not an issue then I can sort out cold bridge with rigid insulation on internal face of the frame? The thermoblocks are expensive and I was rather thinking that whilst they may be a better option. Is it reasonable to just have thermal lightweight blocks below soleplate. And are there any specific ones recommended. I've read on here of many 'blowing out'. It's only single storey and doesn't support roof etc. Thanks!

-

Outdoor area- stones/self binding other options?

daunker replied to daunker's topic in Landscaping, Decking & Patios

Should point out it's just foot traffic outside area won't be vehicles parked/driving on its does that influence the grids, the neighbour has them seems to work for cars -

Hi I have an area at back of property which I have put on type 1 and intend to whack. My hope was to slab some of it but funds won't go that far. I was going to put terran membrane down after whacking it and then have been suggested to use driveway (self binding) gravel, rather than clean loose stones (which are problematic to contain and less comfortable to walk on). But Im concerned a self-binded solution won't 'look as good' i've seen the stuff used for paths and seen it puddling in heavy rain and imagine even when damp it'll track into the house. Wondering about a skinnier base and then a top dressing of the 20mm size stones/gravel perhaps with a gentle whack? Or is there a better option. It's about 5x20m so a big area! The other thing is I'm not sure how to edge it, was minded by the modern 'sleepers' as easy/quicker to put down than edging stones and will last fairly well. I appreciate a lot down to personal preference but would really value any insight on it, it's rented out ATM so budget conscious and open to all ideas. Fingers crossed! Thanks