NewToAllOfThis

Members-

Posts

97 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

NewToAllOfThis's Achievements

Regular Member (4/5)

2

Reputation

-

Thanks for the reply, the builder did all the plumbing for the waste so as mentioned not sure he knew that testing was required. No actual loft so will need to cut the plasterboard to get to the vent pipe join to the tile vent. How do you stop the air escaping through the plug hole and overflow or will the water in the u-bends be sufficient for the air test Sounds an expensive problem

-

Thank you for the replies, that clears up my till receipts. Just wondering if anyone can explain the question regarding how do you fill in the VAT form description when you have various items on one invoice and there is not room to describe them all in the space available. I guess it is one line for each invoice on the form. Is Waste or water fittings good enough ?

-

I have a lot of till receipts rather than a full invoice and also some full invoices but they don't have any address details, some have an account code where it was the only way I could get a discount as not having a trade account. Have people managed to claim VAT on just a till receipt or no address on the invoice? Where you have a number of items on a single invoice, how do you complete the description as there is not a lot of room to describe all items on the VAT returns form? I wonder how it will work with the new VAT claim method as they don't want the invoice so they will not be able to check unless they ask for the invoice and then what happens ?

-

Not ready to submit forms yet but created a spreadsheet similar to the old VAT claim form and scanned every invoice and now this change. Scarred to have a look at the online version in case it starts a clock ticking down on the 6 month window. Looking at the new paper form if it is a copy of the online then the main change are that it asks for the VAT registration number, also wants the total amount and the VAT amount information rather than just the VAT amount for invoices where the VAT is shown separate. On the old system where the VAT wasn't shown separate it just asked for the total amount, from the new paper form it seems to want you to calculate the amount of VAT as it again asks for total and VAT amount, unless the new form is incorrect and will be changed.

-

Hi, we have UFH with auto balancing actuators, this was installed by the builder and then the plumber installed the boiler and connected up to the UFH manifold. The heating output water splits between up and downstairs with a simple Tee fitting. He installed 2 way valves on the pipes to both floors. Is the 2 way valve required before the manifold as I thought the auto balancing actuators would control the water flow and if the UFH has reached the correct temperature then they would all close and water wouldn’t flow. Hopefully I have explained it clearly

-

New Phone Line from Pole - Prep

NewToAllOfThis replied to richo106's topic in Networks, AV, Security & Automation

Just read the BT Openworld document and seems that Gigabit fibre is only required from December 26. I can't believe they can charge up to £2000 for a single dwelling. I hope it isn't a requirement now as the infrastructure doesn't exist where we are building, I think the best they can offer is FTTC and it then runs on poles to premises. To get FTTP will likely mean digging the road for around 400 metres. Should I put some trunking from front of the premises to the property so there is no need to dig the driveway up in future. -

Hi, Been researching frameless balustrade suppliers and the price for what is the same spec varies from £3200 to £5500 for a run of 5 metres with two sides of 1 metre each creating a U shape. One question, is a gap normally left between the glass panels or is there a rubber or sealant filler applied between them as I guess they need room to expand. Has anyone used any of the following companies: Trade Balustrade Origin Architectural Ltd SHS Balconette

-

Thanks to help from Nick, I think I have now worked out all the connections. I had already installed 15mm pipe before realising I could have used 10mm to the taps. I have put dedicated runs to both toilets as it gives the option to use some form of rain / waste water harvesting in future.

-

We have an invoice for supply of all bathroom items which include a bathroom cabinet which are all listed on the invoice but them only one total excluding VAT is shown, the VAT and the total price. As I understand, VAT can not be claimed on a bathroom cabinet and some other basic items listed. The company will not itemise the individual items as they say it is a special package price but I guess they didn't want me to see if I could get some items cheaper elsewhere. Has anyone else had this situation and what approach have they taken claiming the VAT

-

Our front opening is 1500mm wide by 2200mm high and leads straight into the hallway and upstairs. Underfloor heating downstairs. Looking at either 0.87 or 1.1 W/(m²·K) versions. price difference for the 0.87 version is additional £1050 Any comments appreciated as to what the difference in heat loss will be in money terms and also what the general warmth / cold areas will be.

-

Pressure Reducing Valve - Where one or many

NewToAllOfThis replied to NewToAllOfThis's topic in General Plumbing

Thank you for the replies, starting to understand what I should be making sure is agreed with the plumber. The boiler will be in a very small area so not sure if the 837 will be a bit too big. I think the shower has a maximum throughput of 15 ltr/min and we are likely only to have one running at a time so could I get away without having a storage tank? We have temperature controlled mixer showers but the taps to sinks are standard mixer taps, does the pressure from hot and cold feeds into the taps and shower have to be at the same pressure to stop the water being forced back down the pipe from the higher pressure feed. What is the benefit of having the WC's at higher pressure, will they take a lot longer at 3 bar than 4 or doe it stop a problem with toilet being flushed when someone is showering. I've noticed that I need a Double-Check Valve on the mains inlet, would this go between the mains inlet and Stopcock or after the stopcock, and where should the Y strainer that JohnMo mentioned. Any nice diagrams floating around showing layout for how all the bits go together. -

Although not tested yet, I know the incoming pressure in high coming into our new property and neighbours all say pressure is high. Is there a set pressure that should be distributed around the house or does it vary depending on size of property, number of bathrooms, type of heating, etc. We are having a combi boiler installed so no water storage tanks, I assume everything will therefore be at the same pressure throughout unless regulators are added? Should just one PRV be fitted where the mains water enters or should more than one be installed for different applications. We are having an outside tap fitted, would it be better to fit this before the PRV from the mains water so it has a high pressure ? I guess there are good and bad PRV's, can anyone recommend a sensibly priced reliable unit. .

-

Samsung infinite ovens

NewToAllOfThis replied to Coffeepotclaire's topic in Kitchen & Household Appliances

They are changing their ranges and calling all their products a 'series' number, they are on series 4 old prodcuts, 5 fairly new and 6 new. I was told this will standardise across their whole range of products so you may notice it will come back out looking almost identical but be given a series number. You will also notice products going in and out of stock, even though some are just out of stock they say 'No longer available' and then appear a week or two later. We have the series 5 oven and microwave, not installed yet but look very nice. The microwave kept saying no longer available even though it was a new product, then it just appeared. The Samsung website is awful for user experience. I just hope their products are much better as dual cook oven look very useful -

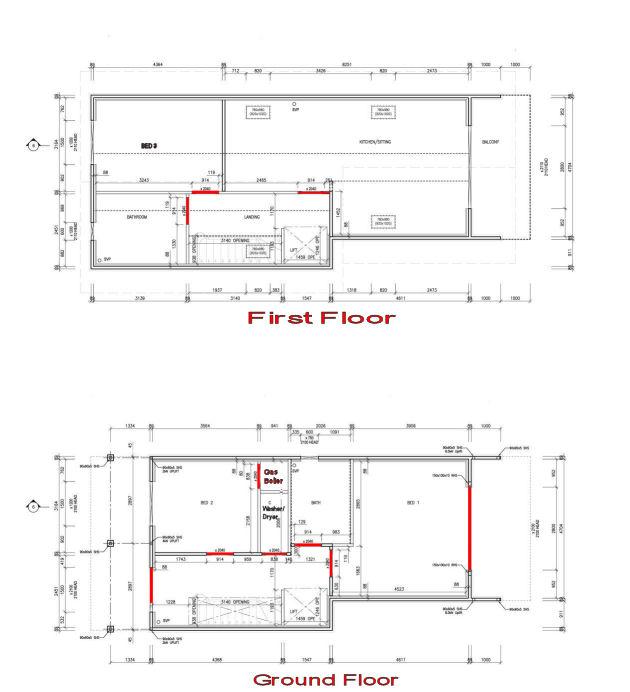

Hi All, Is there an easy way to work out if and where Fire-Doors are required. I have shown all the doors in RED I have attached our new build layout. Kitchen/Diner is upstairs, together with bedroom and bathroom Downstairs there are 2 bedrooms and bathroom. The Gas Boiler is in a cupboard with door access in bedroom, there is also a washer/dryer in the downstairs cupboard. Any help appreciated