MortarThePoint

Members-

Posts

2168 -

Joined

-

Last visited

MortarThePoint's Achievements

Advanced Member (5/5)

241

Reputation

-

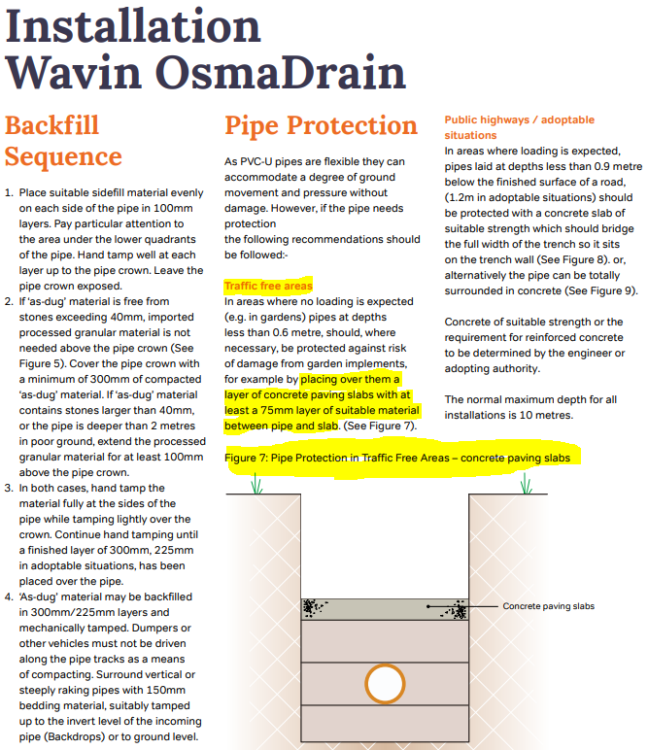

Osma (Wavin) advice on protecting shallow pipes. I've put 100mm over the pipe crown everywhere, so can use slabs where less than 600mm and just backfill (inc. 40mm stone) elsewhere.

-

It is a tiny amount and I think there is always going to be a little bit of liquid left against the seal by the nature of the fact that the MAC8E's pipe section is a narrower ID than the Spigot's OD. Like so much of this game, it's really annoying when you've worked hard to get it right and then the tolerances conspire against you. I think you're right, time to crack open a beer.

-

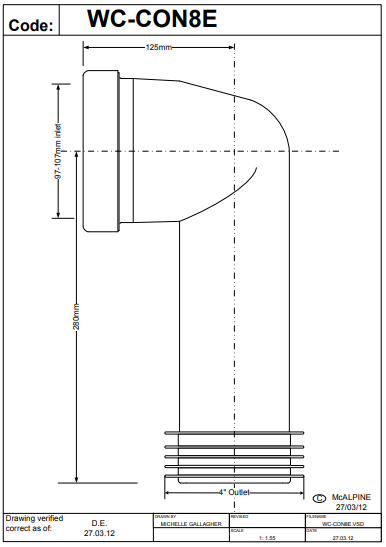

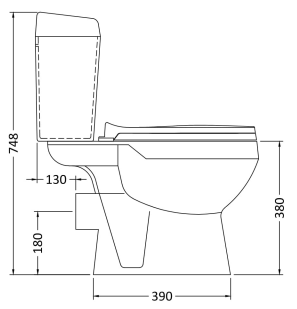

By measuring the height (107mm) above tile to the underside of the MAC-8E's 'trumpet spigot flange' and based on a crude measurement of the MAC-8E drawing's 'trumpet spigot flange' O.D. (136mm) I get that the spigot height of this toilet is actually 175mm (107 + (136/2)) not the 180mm it's supposed to be. That's the main route of my problem. The tiling is also likely a tad thinner than expected, but the spigot dimension is the main issue.

-

I guess hunting around for a toilet with a 190mm spigot height (or 185mm minimum).

-

Actually, thinking about it there is often going to be some water there since the toilet spigot is larger diameter than the pipe section

-

May mean I have some waste water permanently sat in the connector against the seal to the toilet pan. Isn't that a concern?

-

I haven't drilled any holes for the toilet screws yet so that wouldn't be an issue. I do have some spare tiles. Are you thinking I could create a low platform for the toilet to sit on?

-

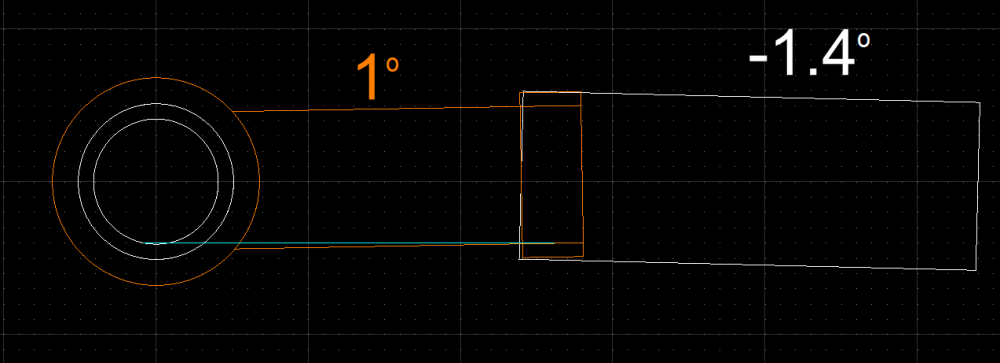

I'm using a McAlpine CON8E and it connects up nicely except my soil pipe is too high relative to the tiled surface meaning the connector's pipe section doesn't have a fall. In fact it slopes slightly the wrong way. If I raise the toilet up on 5mm packers, this pipe section is level. Ideally I'd want a fall of about 1:40, which would mean having the toilet 10mm above the tile. I can't change the height of the soil pipe as it is all boxed in so I'm wondering what to do? I think the spigot on the toilet is lower than it says in its dimension drawing (180mm) and the tile build-up is thinner. I've attached some pictures of the situation and then a single picture of it with 5mm packers under the toilet.

-

Insulated hot and cold water pipes?

MortarThePoint replied to Alan Ambrose's topic in General Plumbing

Probably still less wasteful than whizzing hot water round a circulation system all day long -

Insulated hot and cold water pipes?

MortarThePoint replied to Alan Ambrose's topic in General Plumbing

The concern with uninsulated cold pipes is condensation forming on them. I think a 15mm pipe is something like a litre per 10m of run. A shower at 6L/min would clear 10m of pipe in 10s. I've even wondered about the benefits of a circulatory hot system Vs just filling the toilet cistern from the hot supply. The cistern fill would clear the pipe of the cold water before the basin tap get turned on. Insulating hot pipes for between uses is pointless in my mind. Others may have experience to the contrary though. Also, regs require it. -

Loads of colours available to add to white cement. White cement is more expensive (2x I think) but small difference Vs labour costs. If achieving the colour using an additive rather than sand, check how consistent it will be. The brickie's labourer may vary the dose and that could create banding. There is an expensive new college building I see in Cambridge and it's a dogs dinner due to this issue I think. You can influence the colour a lot with choice of sand and that should be more consistent as long as everyone understands. I'd be cautious of going the lime route. Fewer brickies have experience with it and it can be less tolerant (e.g. temperature). In the right hands it's great and looks brilliant though.

-

Rainwater Drainage Basics

MortarThePoint replied to MortarThePoint's topic in Rainwater, Guttering & SuDS

It's really a struggle to maintain 1:100 with a couple of turns. I've wondered about sending the (remaining) furthest downpipe (at 27m) on that run into a channel drain going along the edge of the house. That runs at the surface and you can get a 110mm end cap. That would buy me about 40mm if the channel was laid with a 1:100 fall or 80mm if laid level. 80mm would allow the remaining 22m to fall at (425 - 110 - 25) : 22000 = 1:76. A channel drain here is a bit random though. -

I was thinking the other day that a poor tiler can make expensive tiles look cheap, a good tiler can make expensive tiles look expensive but a great tiler can make cheap tiles look expensive. Hard to be sure, but from the picture the tiles themselves look fine.