Nick Laslett

Members-

Posts

687 -

Joined

-

Last visited

-

Days Won

1

Nick Laslett last won the day on February 11 2025

Nick Laslett had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Nick Laslett's Achievements

Regular Member (4/5)

365

Reputation

-

Some useful posts in this thread: And here.

-

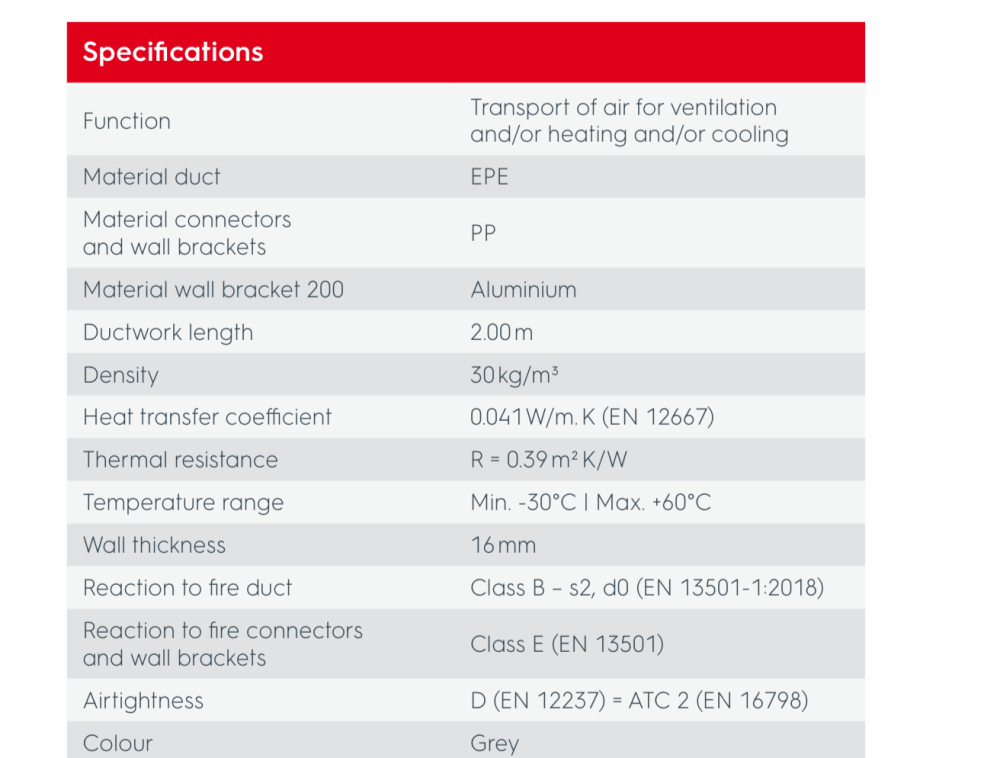

I am a little surprised by the thermal performance of the Ubbink insulated ducts. Is this the Aerofoam product? Thermal Spec is 0.041W/m.K The Zehnder insulated ducts were too big for my plant room, but I did buy a 1 metre length. Their U-value is 0.035W/m.K What was the outside temp when you took the photo? 0°C? The insulation on the filter box is great. I’ve used 32mm armaflex with steel spiral ducting, I hope that performs. System still not commissioned, so will have to wait to get a similar thermal image.

- 99 replies

-

- mvhr vents

- filter

-

(and 1 more)

Tagged with:

-

Here a some of my fermacell bookmarks from when I was doing my original research. https://roselea.co.uk/2022/09/16/fermacell-and-plasterboards-arrives/ http://drubbard.blogspot.com/2015/05/boarding-walls-first-floor.html http://drubbard.blogspot.com/2016/02/jointing-walls-and-ceilings.html https://victorianhouseproject.blogspot.com/2016/01/fermacell-gypsum-fibre-boards-and-where.html

- 78 replies

-

- dry lining

- fermacell

-

(and 1 more)

Tagged with:

-

@Great_scot_selfbuild, I loved using fermacell. But I knew I was going to do this part of the build myself. You are much better paying for professionals to do the dry lining and then get a plaster skim. If you don’t like how flimsy plasterboard is, just get the dry liners to put up OSB first. Like all good project management decisions, you can possibly save money going down the DIY route, but it will just take a lot more time.

- 78 replies

-

- dry lining

- fermacell

-

(and 1 more)

Tagged with:

-

ICF Window Render Reveal

Nick Laslett replied to WiltshireLink's topic in Insulated Concrete Formwork (ICF)

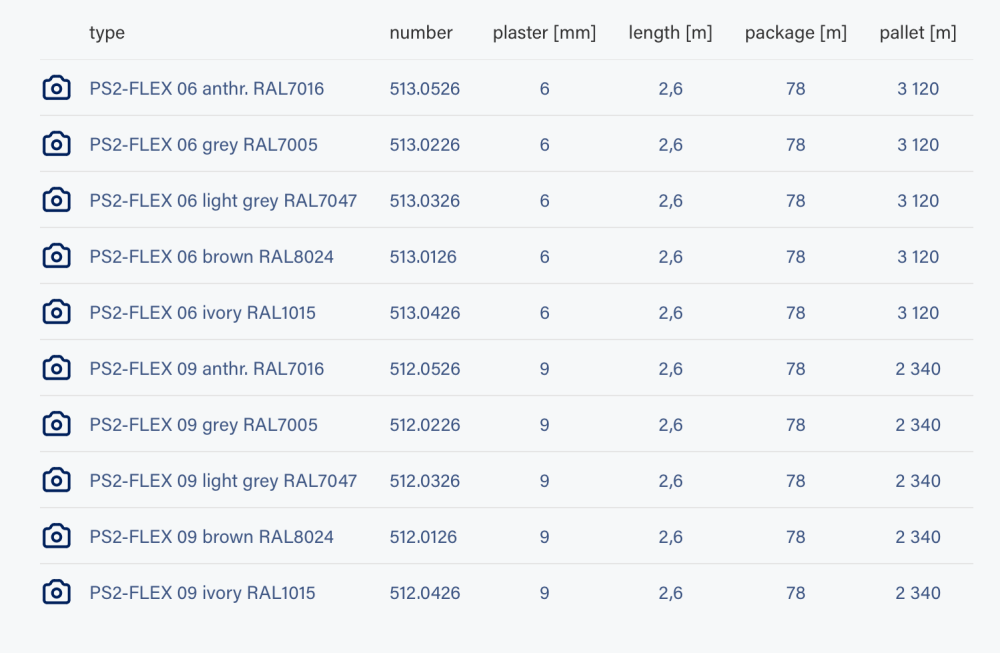

These two threads might be of interest. These beads do come in a few different colours. https://likov.com/ps2-flex-colour-2d-window-reveal-bead-with-protective-lip-g177 -

Floor slab insulation. Test my logic please?

Nick Laslett replied to saveasteading's topic in Barn Conversions

I believe that the graphite EPS not only has slightly better U-value, but also reflects more heat back at the source. Which I don’t think u-value measures but I might be mistaken. BASF Neopor is the stuff used in my ICF blocks. -

Rebuilding after demolishing question

Nick Laslett replied to dustyb's topic in General Self Build & DIY Discussion

If price is your primary concern. Take a look at this channel doing an ICF Ecobrix build. https://www.youtube.com/@TurningRosemountUpsideDown -

Recommend a thermometer gun thing.

Nick Laslett replied to Russell griffiths's topic in General Self Build & DIY Discussion

Definitely a difficult subject area to navigate. Loads of misinformation and dirty tactics from manufacturers. This is a very good forum for discussions about thermal Imaging cameras. https://www.eevblog.com/forum/thermal-imaging/ This shop is good place for info and comparisons, not sure if they still supply the UK. https://eleshop.eu/inspection/thermal-imaging-cameras.html I bought the Hikmicro B10, £299 on Amazon. https://www.amazon.co.uk/HIKMICRO-Resolution-Measurement-4°F-1022°F-Temperature/dp/B09FTFHTPR -

Triple glazed Vs double glazed patio doors

Nick Laslett replied to flanagaj's topic in Doors & Door Frames

@Benpointer, this looks like a great product. Amazing U-values are possible, but the glazing units just get thicker and the frames even more so. These are 54mm thick glass units, with 94.5mm thick frames, you could fill with krypton and get even lower u-values. My wife would throw a fit if I had suggested frames this big. I did look at C.U.in glass which adds a plastic sheet in between the 2 panes of a DGU cavity and gets a window pane U-value of 0.4 for a 32mm thick unit. Not sure what the catch is? But they don’t seem very popular. My wife wanted glazing bars, which don’t work with C.U.in. https://crystalunits.com/c-u-in-triple-glazed-glass/ @craig, do you have any experience with C.U.in glass units? Another factor that is not too common in England, but seems quite normal in Scotland and Ireland, is check reveals. We have these as part of our ICF blocks, so it adds 25mm of insulation to any window frame. We didn’t bother with detailed PSI calculations for this thermal bridge, but as our frames are only 58mm high, the 25mm overlap of the check reveal provides a lot of insulation. https://www.facebook.com/thekirranefamilydiaries/videos/these-are-the-thermohouseltd-reveal-blocks-for-the-windows-and-doors-i-will-make/1065230795004305/ -

How do you install Compriband _under_ windows?

Nick Laslett replied to Alan Ambrose's topic in Windows & Glazing

For what it is worth, OB1 Clear is intended for exterior purposes if you need a clear version of this type of adhesive. https://ob1original.com/uk/wp-content/uploads/2025/10/OB1-Multi-Surface-Construction-Sealant-Adhesive_Silver_Clear_TDS-1.pdf -

How do you install Compriband _under_ windows?

Nick Laslett replied to Alan Ambrose's topic in Windows & Glazing

For me that was the joy of self building. Never having installed windows, I thought compriband was great. Followed the YouTube video, what is not to like. Here is my playlist of many window install videos. https://youtube.com/playlist?list=PLMqBydLyN5jH5KYILUMXeVpz3dljZLrPE&si=zTzode7Uz_pSIjb5 -

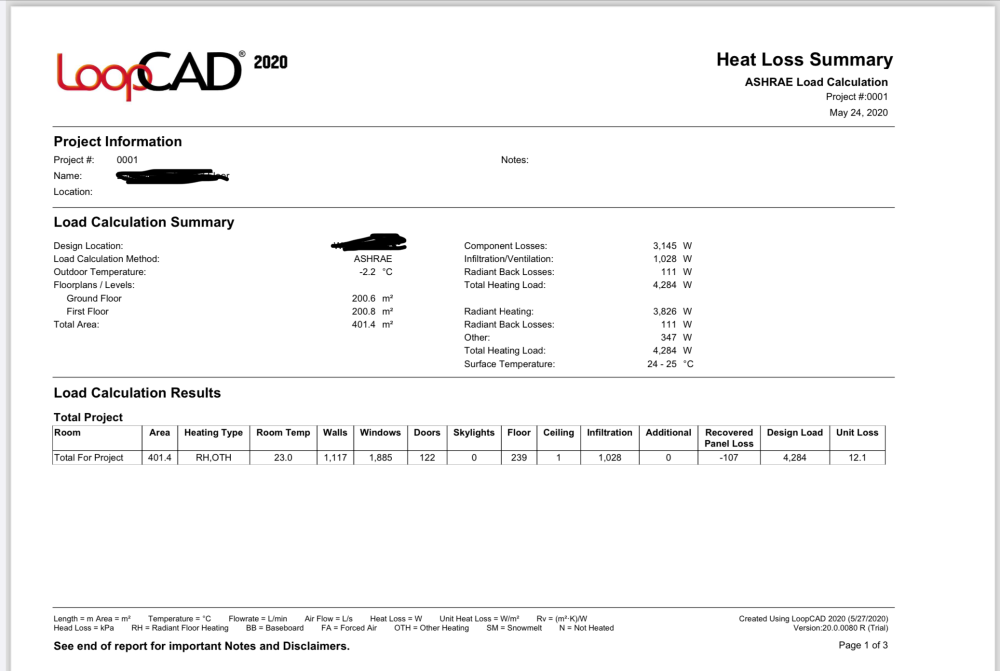

@Great_scot_selfbuild, something not quite right with the LoopCAD inputs. Ask for the Heat Loss Summary Report, that will include target room temp. I have attached mine as an example. Do you know the design outside temp? My flow temp today with a 1°C outside temp, is 28°C. Room temp is 18.4°C. In my original LoopCAD design, I had target room temp of 23°C, which had a flow temp of 30°C, with a floor temp of 25°C. Looking at the attached report, the floor temp is consistent with mine, but the flow temp is 46°C. What is stopping the heat getting out of the floor? Maybe they forgot to add the insulation under the floor in LoopCAD. The Heat Loss Summary report will show the heat loss through walls, windows and floor.

-

Triple glazed Vs double glazed patio doors

Nick Laslett replied to flanagaj's topic in Doors & Door Frames

Good day for a test. (Did this about 95min ago) Outside temp according to the ASHP is 2°C. House Internal air temp is 18.4°C Here is a photo from my thermal imaging camera. The window pane glass is at 12°C, look at the heat outline of my body showing the reflected heat, which is 15.1°C. The frame is at 9.1°C. -

Triple glazed Vs double glazed patio doors

Nick Laslett replied to flanagaj's topic in Doors & Door Frames

I have to go against the grain here and say that the frames are the main thing to think about. A 26.8mm DGU, with 6.8mm-16mm-4mm glass, filled with krypton gas will give you a window pane u-value of 1.0. The two different thickness of glass give the improved sound reduction. The soft-coated, low-emissivity (low-e) coating makes the glass reflect back into the room a sizeable amount of body heat which stops the glass from feeling cold to the body. If you can afford frames thicker than 28mm, then triple glazing can be brilliant, but to outperform a 2G unit the gap needs to be a minimum of 12mm. A 32mm TGU will give you a U-value of 0.8, you need to go to 44mm for a U-value of 0.6. For frames, you want something with the latest generation thermal break, like aerogel or PURe. SWMBO wanted Crittal style windows, so we have 2011 era Smarts Alitherm frames, with 1.0 U-value glass. The whole window unit u-value is 1.3. This is all due to the frames ancient tech polyamide thermal break. Remember the glazing unit only has a 25 year lifespan, max. Then all the gas has leaked out, the seals have gone and there is no vacuum. Then the unit needs to be replaced.