Great_scot_selfbuild

Members-

Posts

255 -

Joined

-

Last visited

Everything posted by Great_scot_selfbuild

-

Timber Cladding, Zinc Guttering, Brise Soleil and External blinds

Great_scot_selfbuild commented on Thorfun's blog entry in West Sussex Forever Home

@Thorfun stunning house and cladding in particular. We’re doing cladding too (different style) - what did you use for fire stops? -

I'm comparing UFH quotes and I've had to prompt for the detail of the pipes and materials that would be used by one of the companies - has anyone got experience of these (failing experience, I'll take an opinion):AmbiFlex-M16-UFH-Pipe-Datasheet.pdfAmbiente TraffiPipe T16 Pipe Datasheet.pdf All I'm really comparing this against is the quotes I've had from other suppliers direct, but I'd prefer to get the UFH design and supply from the same company I'd be getting the ASHP from (again, I'm still weighing up lots of options).

-

Thank you for all the very helpful input - the cooling comments haven't been lost on me at all. We do like a cool bedroom and prior to having the detailed SAP calcs and part O modelling done, we were looking into AC / ASHP cooling modes and how effective they are/aren't (i.e. as others have said - don't expect anything immediate or particularly noticeable over a short period of time). We nearly got taken in by some of the MVHR / combo-cooling sales pitches but were saved a lot of £££ by some advice from here. I'm happy to say our plans have reverted back to our original basis (simpler than my OP): Wet UFH downstairs, single zone (open circuit, single zone valve control (which we may / could connect into our KNX system - we're starting with a simple KNX implementation but with the wiring and fabric of the design so that we could expand it later when our bank balance has recovered...). Electric UFH pads in the bathrooms (tiled - this is more for comfort & experience rather than as a 'heat the room' source). These could be connected into the KNX system too. Electric towel rails in bathrooms. Question re: UFH pads under tiles: We're looking at these two options; they would be installed on top of 22mm Caberdek floor with tiles on top. Has anyone any advice on using the self-levelling compound (10mm) on top of this sort of wiring? How do you get it level and how do you prime / waterproof the floor and timber edges? (10mm is so shallow - the 75mm wet screed is easy to visualise). UFH pre-wired pads: https://www.thefloorheatingwarehouse.co.uk/product/150watts-m²-thermrite-mat-full-self-adhesive-backing-for-easy-install/ https://www.thefloorheatingwarehouse.co.uk/wp-content/uploads/2021/11/ThermRite_Mat_Instructions_150_CR.pdf UFH loose wire - pinned down to a set layout/principles, but allows us to fit neatly around objects like bath, toilet, vanity unit etc.: https://www.thefloorheatingwarehouse.co.uk/product/thermrite-dual-core-heating-cable/ Installation manual: https://www.thefloorheatingwarehouse.co.uk/wp-content/uploads/2022/11/ThermRite-In-Screed-Cable-Installation-Manual.pdf I'll dig out some images of the house layout if you're interested.

-

Looking for advice on electric UFH pads/loose wire laid to a plan. We don’t believe we’ll need it much if at all, but we’ve not met or spoken to anyone who has used it - effectiveness, cost, installation. Here’s our situation and some questions. Our build will have a passivehaus level of thermal and airtightness. I’ve visited a similar size/build where they have wet UFH downstairs and only towel radiators in the bathroom upstairs; they have no issues with warmth upstairs. (Numbers for ease of reference / comment) Current thinking / starting point: Wet UFH downstairs Towel rails upstairs (electric) Electric UFH pads in bathrooms (electric) The back-up: Install electric UFH pads in the bedrooms (not covering the whole floor area) as a reserve for cold snaps and the ability to apply some heat to the bedrooms that could be relatively effective (i.e. you’d be walking on it and so the impact of turning it on would have some relative immediacy of effect). Alternatives we’re considering: 5. Install wet radiators (2 bathrooms) connected to the ASHP. 6. Would prefer not to install wet heating to the bedrooms (space, cost, don’t believe we’ll need it). Question about electric UFH: 7. I’ve had slightly confusing explanation from a UFH supply company (clearly in sales, not technical). They described the electric pad installs (for both under tile and under carpet) as: a) Tile backers required (are they essential). b) Electric heating pad, or loose heating wire that can be laid to one of their designs, which allows it to fit around items (beds/baths) easier. c) Self-levelling compound is mixed up to lay over the wire (as shallow as 10mm). We have a timber frame and timber first floor (Caberdek) and so I asked about this needing to be waterproofed - he didn’t have an answer. I appreciate that’s quite a download, any comments/sanity checks appreciated.

-

It’s a 2-storey house, the ring beam (containing beam & block floor) is suspended off the floor. Ground floor has high ceilings of 2910mm, posi joists are 425mm deep and my measurement of the first floor FFL is 4m from ground level. Because of the uneven ground, the required min 150mm air gap and SE adding another beam in under the floor (structural detail architect didn’t allow for) this is why the as-built was unable to be accurately reflected by the architects design drawings. Frustrating, yes. A reality of very uneven (by mm) ground that we couldn’t simply flatten because of tree root protection areas, also yes. Hope that helps explain / understand.

-

@Mr Punter Thanks - our starting point had been this builders merchants which appears to advertise each slab as being £35 vs £7, but your link highlighted that it may well be a pack of 4 (but I've re-checked the website and this one definitely reads as being £35 per slab (which would be ridiculously expensive!) https://www.coversmerchants.co.uk/rockwool-rwa45-insulation-slab-1200-x-600-x-100mm

-

Just digging around to check this company is not a scam - it sells at a very favourable wholesale price (but only at large volumes i.e. multiples of 80 sheets, which may be the reason why they're not really a direct competitor to most stockists). https://buildwholesale.co.uk/shop/building-supplies/insulation/internal-wall-insulation-insulation/partition-wall-internal-wall-insulation-insulation/rockwool-rw-slabs-partition-wall-internal-wall-insulation-insulation/rockwool-rwa45-100mm-x-600mm-x-1200mm/ Has anyone here used / heard of them?

-

Our Velux is partially installed - is this amount of movement on the trim around the window (not flashing) normal? Is there any way to tighten it up? thanks IMG_9154.mov

-

I like this positive outlook, and you may be right in the sense that he is very matter-of-fact in the sense that his report simply states what he has seen at the time, as he’s said in the past that if he reflects what is in the design but we don’t build to it, then his report may be misused. I hope to get this clarified.

-

Thank you for this. This is exactly what I have been poring over but recognise that just because I want the floor height to be the answer doesn’t mean someone else sees it the same way - you’ve summarised it the same way I (biased) view it, which is reassuring. I did ask about it at plans stage but because of the uneven ground and complexities of the suspended floor structure there were always going to be likely differences between as-designed and as-built. Then the SE added in a beam under the floor that raised it another 150mm and it caused another headache… you get the idea perhaps. (Note to self - I really should do a blog) It’s very robust, SE-designed, steelwork, lots of huge joists, 32mm deck. I do wonder if the BC forgot all about the conversation where he said that the deck level would be the level measured to. @kandgmitchell thanks for your reply.

-

Just need to vent a little frustration and see if I’m the only one… I imagine like many professionals, this comes down to personalities and probably workload, but getting hold of my building control inspector (private) to actually speak to is a real challenge if I can’t take a valuable day off work to be on site for the day he visits. He visits, leaves, writes report and often asks for documentation I’ve already submitted, or refers to details that are inaccurate and need correcting. Latest visit he has stated that the first floor height to ground is over 4.5m and so we need a full fire-protected stairwell. This will result in a lot of fire doors. I previously discussed this with him in person (on an earlier visit when I’d taken a day’s leave to make sure I could speak to him); the ground slopes and the finished house will have decking on 3 sides at floor level, and so all those windows are very comfortably less than 4.5m (this was his words - so in this case it’s a pragmatic first floor to the surface outside the window, rather than ‘ground’, which is below the decking). This leaves two windows at the end where ground is highest and the first floor height to ground I’ve measured to be 4.0m. Now, I’ve read the Part B many times, and it just refers to the ‘first floor’ height which, being as it doesn’t say first floor window, I have taken at it’s word as first floor height to ground. Has anyone experienced or seen it defined as the window to ground rather than floor? (Our FFL to ground is 4m and the window ledge is, from recollection, 550mm above FFL). I’m looking (hoping) for support / examples that it’s FFL to ground. I am prepared to be disappointed however 😕. We’re aiming for a high standard of build, but I’d rather have the choice over which doors to fit rather than have fire doors imposed upon us.

-

Internal window reveals/Fermacell

Great_scot_selfbuild replied to Russdl's topic in Plastering & Rendering

@Russdl Thank you for this thread! Just read through the whole thing and it has completely changed my outlook on using Fermacell (I only started looking into this yesterday, trying to understand the process, work out costs etc.). Whilst I wait for some plastering quotes to come back I was wondering about whether this would be a good DIY solution, but time is not on my side and I fear that we'd get part way through and end up getting some of it plastered anyway. Sharing your experience as you have has been invaluable. I hope the end result worked out?- 78 replies

-

- dry lining

- fermacell

-

(and 1 more)

Tagged with:

-

Site entrance gates

Great_scot_selfbuild replied to flanagaj's topic in General Self Build & DIY Discussion

We used this stuff to screen our heras fencing. Just secured it with zip ties. £44 for 50m (2m high) - saved me £££ over the proper screening stuff. Can look thin (if you get right up to it), but if that’s a concern you can always double it up. As for wind, if you can, put it on the upwind side and it’ll put less stress on the zip ties. Weed Control Membrane | Heavy Duty Ground Cover Fabric | UV Stabilised Weed Barrier | 2m x 50m | 50gsm https://amzn.eu/d/9iYC2IZ -

Can't find a brickie (Hampshire). Any suggestions?

Great_scot_selfbuild replied to flanagaj's topic in Brick & Block

@flanagaj I can highly recommend Adam Chandler - https://chandlerhp.co.uk/services/house-builds/ (based in Basingstoke) Best of luck, stay positive! -

Yes - planning to do this with the internal walls and. There will be a void in the ceiling (small flat section at top). All these comments are very useful reminders - I’ve thought about many/most of them, and am creating a checklist but I’m looking at one aspect there’s a risk of forgetting another!

-

Yes, it'll need to be ventilated. No matter how many times I mention that we need a mesh installed, this seems to be something that is actively ignored and it looks like I'm going to have to go and add this to the list of stuff I need to do myself! (has anyone got any recommendations for mesh they've actually used? I'm sure I can find some, but no doubt some products will be easier to use and handle than others, so I'd like to hear some first-hand experience)

-

Fabric and ventilation heat loss calculator

Great_scot_selfbuild replied to Jeremy Harris's topic in Heat Insulation

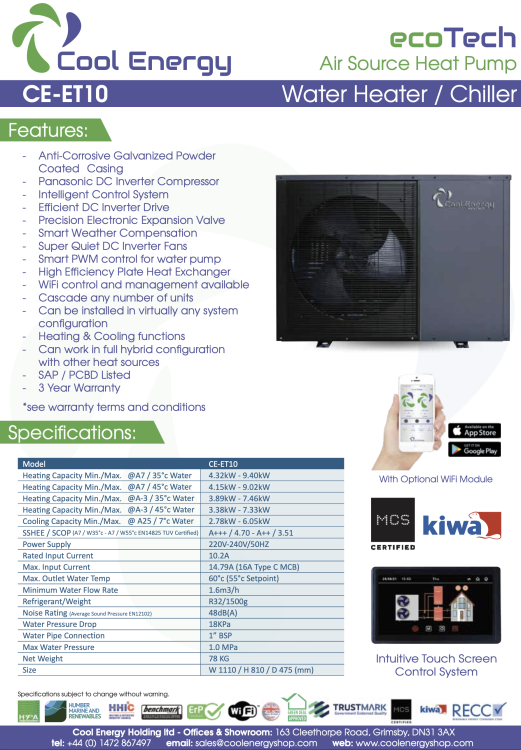

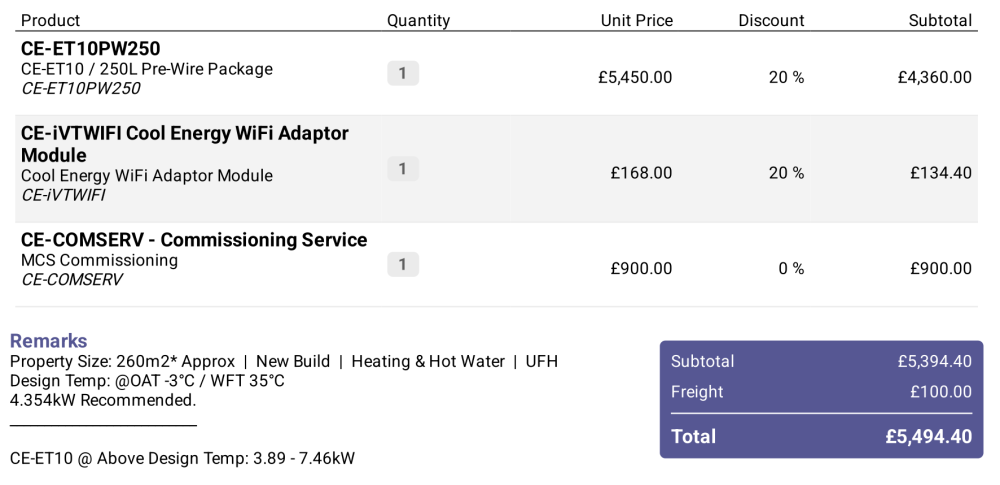

@JohnMo your reply her (along with others) has prompted me to spend quite a bit of time over the last week doing some reviewing of previous quotes, get a couple of them updated, as well as investigate sourcing the ASHP and DHW myself without the grant and have a plumber install it. The majority of them quote between £12 - £14,500 before the grant, resulting in near to £5k after the grant. I've a quote for the supply and commissioning from an MCS supplier for ~£5,500 before grant and so the only cost would be our install cost (the quotes typically have the install broken down as ~£2,500 - £3,500). What do you think of this Cool energy HP? (this would 'only' cost us the install costs). To me, the numbers appear to suggest it modulates up a huge amount (9kW), but not down very well; I'm still on a steep learning curve with all this. I'm attracted by having an installer who is familiar with the make/model of the HP as so many threads are associated with poorly set up HPs. I looked into the Haier one - my main reticence with the less common makes, or going it on my own it the support for them afterwards. Thanks- 203 replies

-

- heat loss

- ventilation

-

(and 4 more)

Tagged with: