sgt_woulds

Members-

Posts

185 -

Joined

-

Last visited

-

Days Won

1

Everything posted by sgt_woulds

-

Exploring the ratios and losses between building elements

sgt_woulds commented on SteamyTea's blog entry in Energy Ideas

Talking of screwpiles reminds of another GSHP project in London; They were using a machine to fit a vertical deep-bore heat pipe. TFL arrived and asked them to stop - less than politely but for very obvious reasons -when it was pointed out that their back garden was directly above part of the Norhern line... -

Exploring the ratios and losses between building elements

sgt_woulds commented on SteamyTea's blog entry in Energy Ideas

I've not been able to check your calculator yet Steamy - no computer at home at the moment. Could it include occupancy levels and biogenic heat sources? I read this recently: The small passive house problem - a solution? - passivehouseplus.ie To my mind, most PH builds have been massivly oversized because it works better on paper. It would be nice to have a tool that advocates for sufficiency. -

Exploring the ratios and losses between building elements

sgt_woulds commented on SteamyTea's blog entry in Energy Ideas

I guess my thinking was, if you have a digger in anyway, just dig a few trenches for GSHP as well. All points taken on board, and I do think GSHP has had its day. I vaguely remember reading in (I think) Green Building Magazine (great magazine sorely missed now that the deathly boring PH+ has replaced it) that someone had built a heat store under the foundations, using a tarmac drive with pipes to heat it up. Maybe it was a school - it was a looong time ago. Back then we had a lot more people willling to experiment. Back when I was installing solar (when the average system was £25000 for 1.5kw), we worked with a some fantastic experimenters and early adopters. One chap - who lived in a Walter Segal designed, and self built house - dug out his entire back garden to shoulder depth using nothing but a shovel and wheel barrow to bury his GS pipes. He was powered by Rum and Wacky Backy and was older than I am now when he started! The soil was removed by barrow to skips at the end of the lane, stored offsite, and then returned for the reverse process. Unbelivably he finished it all in a couple of months. Then he realised there was a leak and had to repeat the process... -

Exploring the ratios and losses between building elements

sgt_woulds commented on SteamyTea's blog entry in Energy Ideas

In the colder regions of America they sometimes extend insulation out from the foundations, or create a skirt of insulation deeper than the foundations. I think this is for frost heave, but it should also make the temeperature under the slab more stable. Could GSHP pipes be layed under the raft at the same time to take advantage of this, or would removing heat under the slab cause other issues? -

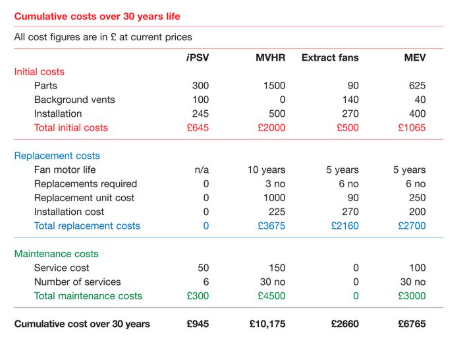

Talking of sums, this is a bit out of date now (I saved this about 5 years ago), but posted for further discussion: This does not include running costs. Perhaps someone here can update the MVHR / MEV costs based on real life experience. I've costed iPSV componants at around £800 for my small 3 bed, two storey house. at current prices

-

These only list temperatures at 1m depth, which is barely below the subsoil in most regions. We are on solid chalk and our topsoil depth is only about 300mm max. At depths of 1.5 to 2m the rock should be at stable temperature. In Hungary i've visited peasant wine cellars built into slopes where the depth above the vaulting is less than two metres and the resulting drop in air temperature is very noticable even in sustained heatwaves. Soil pipe / Earth tunnel. Same thing - just don't confuse it with the other type of soil pipe 🙂 Cooling only. I gather it is quite popular in French public buildings and schools & used by enviro-mentalists (like me 🙂 ) in California . Measures need to be taken to ensure that rain/rodents etc cannot get in. I suspect that clay pipes would work better than plastic to for energy transfer. It's not about energy gain, this is about drawing in cooled air for sustained high temperature situations where subsoil and rock maintain a lower temperature. Even a 2 degree drop from ambient air temperature can be a significant health benefit in a sustained heatwave. Could we see your sums on this? Are you talking about a planned and 'intelligent' passive stack in a well sealed or even 'passive' house or retrofit to leaky fabric? If it is the latter, then none of the ventilation options are perfect...

-

One of the drawbacks I can see with iPSV is hot days and sustained heatwaves with little wind to drive ventilation. Currently we 'sail' or house through heatwaves by closing off all ventilation and shading the south facing windows (curtains, but we are planning external shades when we replace the front windows). Our roof and walls contain lots of woodfibre so we have good decrement delay, and occupation is low during the day so CO2 and moisture levels are not an issue. In the evening after the sun has set and the air temperature has dropped, we open the north facing windows and the skylight and purge ventilate the house - you can feel the cooler airflow and it is very refreshing. However, after a couple of days of heat, the night time temperature difference is reduced (due to radient heat from the earth and buildings) so this option tails off and CO2 levels inevitably rise. We then use portable fans to make life bearable. I know they considered this issue with the Bedzed buildings and tried using ventilation cowls / wind catchers but I don't think it was very successful. It is pretty much a given that climate change will lead to more frequent and longer heatwaves so I'm considering building a solar chimney with soil pipe ventilation - I have to build a patio out the back anyway so it is just a little extra excavation. The chimney might be an issue with building control, but sod 'em! We'll stick it up and see if anone notices! I have a couple of ideas on the design, and I'm considering buying the Handbook of Domestic Ventilation but I don't know if this is a good sourceof information or if there is better text elsewhere. It is an expensive book to take a punt on...

-

With iPSV you don't need a fan in the bathroom or kitchen, to maintain overall conditions. You might want a small fan to assist with kitchen odours though. We do have an extract fan in our kitchen, as an easy route for passive stack was not available. Building from scratch, these problems could all be mitgated at the design stage.

-

Restricting moisture sorbing and release to the surface materials (Gypsum plaster boards) limits the positive benefits of stable indoor moisture levels that natural insulations can provide. Not an issue with MVHR of course (unless there is a sustained power cut in winter with high occupancy) as this is artificially removed. Personally, I'd rather not rely on a mechanical system to stay healthy indoors. Horses for courses. And I prefer my straw hat to tin foil 🙂

-

I remember working in a factory conversion many years ago. They wanted the high vaulted ceiling look, but realised that in winter all the heated air would be above their head. They had a wierd looking single bladed fan to force warm air back down to occupent level...

-

Interesting comments on Gypsum plaster. For our woodfibre IWI, lime plasters are always specified because it is more breathable than Gypsum in the same situation. The sorbative properties of woodfibres (and natural fibres in general), can release moisture quicker with direct lime plasters than than gypsum. Some testing in Germany has shown woodfibre insulation to activily transport moisture from damp structures to the surface, so breathablity is critical. We have an alternative system using battens and boards with plasterboards and flexible woodfibre behind a moisture vapour variable membrane. (M-V VL membrane restricts moisture entering the insulation, but still allows it to breath out effectively when contditions allow. (After the Gypsum has (slowly) released its moisture) This works technically, but holistically it reduces the moisture buffering and moisture exchange rates and is not the best use of natural products. (Essentially, building moisture buffering is almost wholly down the the plasterboard and skim).

-

Thats the point. I'm concentrating on airtightness, then introducing a controlled volume of fresh air, based on internal moisture levels. As long as internal moisture levels are low, the vents remain closed so over-ventilation shouldn't be an issue. Empirically, I have noticed CO2 levels rising pretty much in line with moisture levels and occupancy so I'm not concerned about passing out from hypercapnia using moisture as the controlling method. It would be nice to have some heat recovery and filtration, but since Ventive pulled their product from the domestic market this doesn't seeem to be commercially available.

-

Always a worry when Governments mandate a solution. You'd hope they would learn from past mistakes... Building regs should set standards and highlight agreed solutions, but not prohibit alternatives measures where effectiveness can be evidenced. As to MVHR, I prefer long term ruggedness over perfection. Currently our house is manually ventilated and we have dumb window vents. CO2 is not an issue but moisture can be. I'll add the new moisture sensitive vents and ridge vents just as soon as I finish all the other building works. Only been at it for 12 years so far... @SimonD how did calculate your ventilation and sorbative insulation efectiveness?

-

I planned my house upgrades around using the Glidevale I-PSV system, combined with natural internal insulations for humidity buffering. (Windows ready for inteligent trickle vents, undercut doors, and additinal vents between rooms and a central starircase / stack to ridge ventilation). Benefits - zero power use, nothing to go wrong, and zero maintenance. Occupants are the 'smart' part of the system and we are perfectly capable of sailing the ship as required But now my other half is insisting on an MVHR as she 'doesn't believe' passive stack will work...

-

Was this 'animal glue' made from boiled rabbit skins? I remember seing this used to reinact the 'solvite man' advert. Amazing stuff in tension, but could creep over time with lateral loads. Fully organic and breathable and much nicer to use than modern urathane glues - apart from the smell

-

Passive house Shepards hut ?

sgt_woulds replied to Waterworks's topic in Energy Efficient & Sustainable Design Concepts

I've (tried) to sleep in a 6 man tent with one of these: Outbacker® Pioneer Portable Tent Stove & Complete 2.41m Flue Kit | 2.5 Too hot even when there was only a flysheet as insulation. I vaguely remember that the first 'eco' house built at the Centre For Alternative Technology was massivly over insulated (and poorly ventilated) back in the 90's (?) and inhabitants had to strip down to their underwear until the place was rebuilt. -

What is this made of? Ceiling wood fibre board type stuff

sgt_woulds replied to paro's topic in Building Materials

Glass fibre is almost as bad as asbestos, I hope you wore a good mask! Not to mention the zoonotic risk from rodent droppings... I'm so glad that I don't have to crawl around in lofts anymore 🙂 -

What material did you use for this? How the metalised finish holding up?

-

'Use it, dont burn it' ? Absolutely agree. Costs have been inflated in order to favour the option that maximises shareholder returns in line with modern mantra. I have no problems with on-shore wind turbines - to my mind they have an elegance that compliments scenery, the same as a victorian viaduct. Pylons are an abomination and it is worth every additional penny to bury cables. In most cases for open fields you wouldn't even need to dig up the land. We already have machines capable of snaking conduits underground for hundreds of meters without breaking the surface - they use them in cities all the time. It would surely be much cheaper to doe this in open areas and once you have conduits buried you are future proofed against future upgrades. And protected from climate change apmplified storms. If we need to upscale the machines then that is a manufacturing opportunity for UK firms. We built dedicated machines to build the Channel Tunnel, and they were only used once before being stripped and abandoned! Whilst we have the perfect off-shore conditions and an entire industry capable of building them out of site, we do need to build more on land for energy security purposes. It much easier for a bad actor to take out an off shore connection than a distributed grid on land. Underground cables on land for the same reason

-

Exactly right. If the evidence proves otherwise scientific opinion changes. That is why science is a better touchstone for forming policy than personal opinion. The point is that a significant amount of the evidence and thus (as you say yourself), a significant portion of the scientific community believe in human amplified climate change. When seat belts first came in, Volvo et al had already published significant amounts of evidence to prove their efficacy. The greatest driver of the day, Stirling Moss had his own opinion on the matter and thought it was better to be thrown from a vehicle and had the seat belt achchors on his car (Marcos at the time IIRC) sawn through. When the inevitable happned he was thrown clear but suffered injuries that he would not have if he'd stayed in the vehicle. It was a miracle that he wasn't killed. In a situation where all the evidence tells you our Fossil Fuel addiction will lead to disaster, do you just hope to be thrown clear?

-

Only use unnatural insulations if you are fitting them yourself and can absolutely confirm every detail of installation is impecible, interstitial damp and misery awaits unless you get very lucky with your builders. A poorly installed but breathable natural insulation will generally give less long term issues than a badly installed unatural and non-breathable one. It is important to note that companies that make natural insulations do not generally recommend achieving high U-values with IWI due to the condensation risk to the structure. There is, generally, a sweet spot between 40-100mm of woodfibre that balances the energy savings, cost, and condensation risk. Part L of the Building Regulations for England offers flexibility when retrofitting existing walls, roofs and floors; an improved U-value of 0.30 W/(m2·K) is the target but a ‘threshold’ level of up to 0.70 W/(m2·K) is sufficient, as long as the approach can achieve a payback not exceeding 15 years and is ‘technically and functionally feasible’. There is also a provision in the regs if IWI will reduce the floor area by more than 5% where lower insulation levels are allowed, but honestly, if your barn is that small then you will need to look at alternatives to conventional insulation anyway. Unfortunately these allowances only really apply to an existing residence and are harder to swing for a conversion, but it is worth discussing with your local authority / BCO. For an older building, most BCOs are now sympathetic to the argument that breathability is more important than the ultimate insulation value. IWI requires careful consideration; the breathability and condition of the walls and pointing should be assessed before specifying the insulation solution. The best advice is to have the external walls assessed via hygrothermal software - such as WUFI - which will take all of the site variables into account. Internal wall insulation is more complicated than external insulation due to the way it moves the dew point within the construction. In addition, standard U-value calculations will not correctly account for the sorption properties of natural insulation fibres, nor their ability to pass on liquid water through capillary action. WUFI purely considers moisture issues and how the various elements of the building fabric will deal with the volumes based on site-specific conditions. This is the evidence you need to convince BCO of your inentions. These may help: Rethinking IWI with Natural Fibre Insulation Insulation and retrofit - Finding the sweet spot - The Alliance for Sustainable Building Products (asbp.org.uk) The-use-of-natural-insulation-materials-in-retrofit.pdf (stbauk.org) I can also recomend Back to Earth as they not only have a lot of experience with insulating historic buildings but can provide the WUFI assessment too.

-

Also the toilet cistern becomes a heat source. But Legionnaires' might be an issue

-

That's Scotland's entire population served.

sgt_woulds replied to saveasteading's topic in Wind Generation

Correct hence my earlier post: -

That's Scotland's entire population served.

sgt_woulds replied to saveasteading's topic in Wind Generation

That sentance gets bandied about a lot, but we need to remember that this forum is open to the unititiated who might take it as gospel. In simple terms you can perform a voltage drop calculation to determin which system will have less losses over the same distance with the same size conductors - generally, whether AC or DC, whichever has the highest voltage will have less voltage drop over the run. But efficiency is only part of the decision process, you also need to facter in cost and safety. On the cost front, back in the 2000's when I was installing PV, it was always cheaper to fit a long run of AC vs DC. Pure copper low loss double insulated solar cables were more expensive. I haven't looked in years, but I don't imagine the costs have changed much! We couldn't use 'standard' AC rated cable for DC as you always wanted to finish the cable with an MC plug, not a screw connection wherever possible. With high voltage DC linked to variable(pulsing) solar, screw connections work loose and are an arc risk. The DC plugs are only certified for installation with double insulated solar DC cable, so you couldn't just fit the same MC plugs to an type AC cable. Then you have the safety factor. High voltage AC is always safer than high voltage DC, espescially when the cables are hidden. I've been unfortunate enough to experience shocks from both, and I can tell you neither is fun, but I'm a lot more respectful of DC! High voltage AC can be protected with affordable and easily available RCD. If someone puts a shovel through a buried AC cable, the power cuts in the blink of an eye, and the inverter shuts down. If the same spade goes through a buried DC cable, it forms a direct circuit with the solar panels at full power until the sun sets! Again, I've been out of the game for a long time, and I know that DC RCM are now available for connection between the panels and field cables, but CMIIR, these don't work as quickly as an AC RCD, and are costly . With long buried DC field cables you will also need to use very expensive DC specific double insulated and armoured cables. Or 'ordinary' double insulated DC cables in armoured conduit. It would be usefull to hear from any practicing Solar installers / electricians for their thoughts