Neverfinished

Members-

Posts

16 -

Joined

-

Last visited

Everything posted by Neverfinished

-

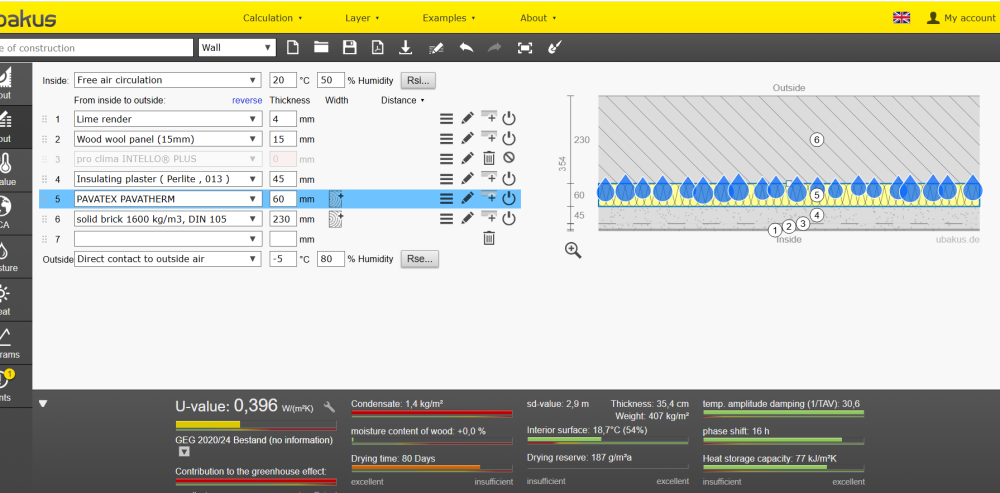

Hi everyone. Thought I ought to return to this, my blog, & give an update on my progress re. this 'o-so-small' a job of hemp insulation to just 2 outside facing walls, details as described at the outset in my initial blog . . & then a few more questions to you guys if I may !! I indeed proceeded to apply to B.C. who in their own time looked at the intended job & merely listened without objections as I suggested "It'll be difficult to meet U-value regs, given that the wall/s insulation 'build-up' is somewhat governed by need to avoid condensation issues/risks", &, he didn't question or refer me to U-value requirements in any way & seemed to go happily on his way -It being an 1897 terrace in a conservation area they seem keen to support such heritage work in our town. And this brings me to ask for your views re. my layers of build-up: From outside to in, its:- 230mm solid old red-brick; 60mm Pavatex WF (already afixed as seen in pic. above in this blog); Going forward now, I'm applying 45ish mm hemp-lime plaster, though have become concerned that with this much depth & weight it might all fall off before its set! - SO . . I've decided to create a simple timber 40mm deep 'partition wall', screwing it onto the WF (thru to the outer bricks), then apply the hemp'coarse stuff' into all the battened sections of the partition,thus providing a greater surface area too for the plaster to stick to. Then addition of 15mm wood wool boards fixed on to the partition; lime-plaster skim finish. . . . I think this is the most likely way for success - any comments appreciated. Also I've been on Ubakus, to get some kind of condensation analysis. (Can't afford a WUFI). Take a look at the attachment on here - but note:- I've had to substitute materials listed 'in Ubacus' to an extent, for those materials I'm actually going to use - but is an interesting outcome - it shows a serious condensation risk. By further playing with the addition of a VCL - Pro Clima Intello+ (see it greyed out in the current pic.) by 'turning this item back-on' the analysis then shows NO raindrops, ie no condensation !! So . .this suggests I ought add such a VCL into the 'build-up' - expensive but presumably worthwhile adding in a VCL as long as I can get it air tight (always difficult) . . any comments re. all this would be most helpful. Many thanks.

- 15 replies

-

- building regs

- insulation

-

(and 2 more)

Tagged with:

-

Thanks again @Redbeard , @Roger440 + all you others on Buildhub who contribute their expertise & help 'have a go' folk like me! Yes, sorry Redbeard I wrongly outlined my suspended timber floor buildup. I actually followed the Ecological Building Sys. video: https://www.youtube.com/watch?v=M1KzqaOgtss for my 'build up'; yes, to be correct, I did infact use the 'blue' Solitex for the cradle & the green 'DA' as vcl atop. And BC signed it off a year ago (not 2 as I'd said) without questioning u-value or anything . ( Returning to my IWI upgrade of 2 adjoining walls - I always struggle calculating U values (on Ubakus), would anyone be happy to run a U value calc. on these walls for me ? Build up is as follows: 'vintage'/1897 Red Brick - 225mm - (lime mortared 'in', no cavity) Baumit Klima RK 38 - 5-10mm - as a dubbing out + adhesive, layer wood fibre boards - 60mm - (T & G 'fit') Baumit Klima RK 38 - 5mm - adhesive layer Medium Hemp-Lime plaster - 45/50mm One manufacturer states a value as 1.26w/m2k @30mm; another states conductivity = 0.07-0.09W/mk. Lime plaster finish coat - 5/10mm The Baumit layers being so thin presumably can be ignored?; note, this Baumit is an NHL lime. What's people's opinion re permeability of an NHL lime in this build-up ? It would be just generally useful to know its u-value, & perhaps it'd help me decide if to go through B.C. (or not!) The figure is sure to be short of the requirement ! I'd rather not increase the hemp-mortar thickness further, I'd worry the extra weight is likely make it 'peel away' from the WF base/backing perhaps! Thanks all.

- 15 replies

-

- building regs

- insulation

-

(and 2 more)

Tagged with:

-

Thanks again to you good folks, @Redbeard & @Roger440 etc for your most helpful but cautionary words. Its now thrown me into a quandary whether to inform them (BC) or not! I'd indeed prefer all were 'recorded' & certified, given the effort & £'s involved. Referring back to the initial/2020 application, an officer inspected the bare room (old plaster already hacked off) & I definitely outlined my intention of continuing with vapour open materials (with existing 9" old brick in lime mortar+repointed in lime) + I outlined the IWI to be WF + hemp lime; I maybe did or didn't specify exact inches of that insulation. U-values not mentioned. I did refer to 'not having excessive depths of build up' to avoid 'the interstitial'. Visiting officer didn't especially specify or emphasise any requirements yet seemed 'pleased' with all my referencing details of my methodology. (This project still unfinished so we can never be sure if it'd be signed off, but who knows). Furthermore, I renovated a suspended floor 2yrs ago, under a BN, insulating 'under' using a VCL as cradle to hold 140-150mm Rockwool, +membrane 'atop'. The officer signed it off even with my honestly declaring the amount of rockwool (surely inadequate to meet Regs @ U=0.25). I get the 'feeling' BC flexible if one pains to strive to honestly do ones best to comply . . . or am I just becoming too self assured & a rude awakening awaits me!? I'll post further developments from time to time.

- 15 replies

-

- building regs

- insulation

-

(and 2 more)

Tagged with:

-

Many thanks for that info mjc55; I came onto the forum now as plan getting the project going again in the next month, & these replies will assist my discussions with BC, as . . they wrote saying application cancelled because I hadn't responded to their enquiry/s 3 years into my application! Stupid of me really! So I will try to retrieve something. Cheers

- 15 replies

-

- building regs

- insulation

-

(and 2 more)

Tagged with:

-

Thanks to you guys, as above - @JohnMo @Redbeard & @Roger440 for your views & input &, on balance, I think I'll bite the bullet & pay B.C. for a building notice; I'm eager to have a record of improvements done for when I ultimately sell the house. You Redbeard offered some clarity to my oversight - as of course its only those 2 exterior facing walls that'd really require upgrade in IWI (+ ceiling ideally too). I'll just add a little more of the story of this (small) project, to keep you in the loop - I originally registered with BC in 2020 to upgrade insulation of these 2 out-facing walls but only ever got as far as fitting 60mm wood fibre to brickwork, the intended 45+mm of hemp lime plastering being too hard to complete on my own - & I even stupidly let the building notice expire too. Pic. below shows current 'state' of the project; So I'll re-apply (+pay) BC again !, complete the 'insulated plaster' work etc over the wood fibre base, with some help this time, to obtain a completion 'certificate'. My house is a victorian mid-terrace, in red brick + lime mortar, in a conservation area but not listed. In my original application I emphasised how I've retained the breathable fabric for vapour permeability etc across the house; BC officer who viewed 'site' at the outset seemed accommodating to the historical limitations to improving its u-value, so I'm hoping to get the same consideration again this time, & complete, without actually attaining the now even tighter u-value. You guys perhaps already know how Approved Doc. L states some interesting 'accommodations', for example :- Vol 1, para 0.9 . . "the work should comply with standards in this approved document to the extent that it is reasonably practicable" para 0.10 says: "traditional dwellings should be improved only if doing so will not cause long-term deterioration of the building’s fabric or fittings . ." Here's for hoping BC will consider my new application sympathetically again now! Cheers

- 15 replies

-

- building regs

- insulation

-

(and 2 more)

Tagged with:

-

Hi all, I'd like to ask a 'general' question about adding internal insulation to ONLY the 2 external-facing walls of a bedroom in my victorian terrace, with regard to what Building Control are likely to require of me, etc. These 2 walls amount to precisely 49.1% of the total 4-walls area of the room. I read somewhere that if an upgrade is below 50% then B.C.don't need to be involved, and thus I wouldn't need to meet U-value requirements etc! Or, do things need to be looked at more holistically & the whole room taken into consideration - for instance - the ceiling was, some years ago re- boarded (but not yet skimmed!) so would B.C. add this in as part of my upgrade (& thus becomes >50%)? I've no plan to add more insulation to the ceiling but there's an existing 200mm of wool atop in the loft space, brought up to Regs & without having to apply to BC ! Also, to ask opinions of folk on here about whether its worth all the 'faff' of obtaining B.C. consent for these smallish, almost DIY projects - For myself I'm keen to comply since, when I eventually sell (10+ yrs hence) I believe a search is made, for the sale documents, to ascertain if home improvements/works legitimately comply with Regs. But it seems to me the public commonly are quite blasé about the whole matter, + some tradesmen 'forget' to apply on behalf of client, on small jobs at least. This 'delinquent' attitude seems quite common to me. Am I right this comes back to bite the house-owner eventually? Any comments much appreciated.

- 15 replies

-

- building regs

- insulation

-

(and 2 more)

Tagged with:

-

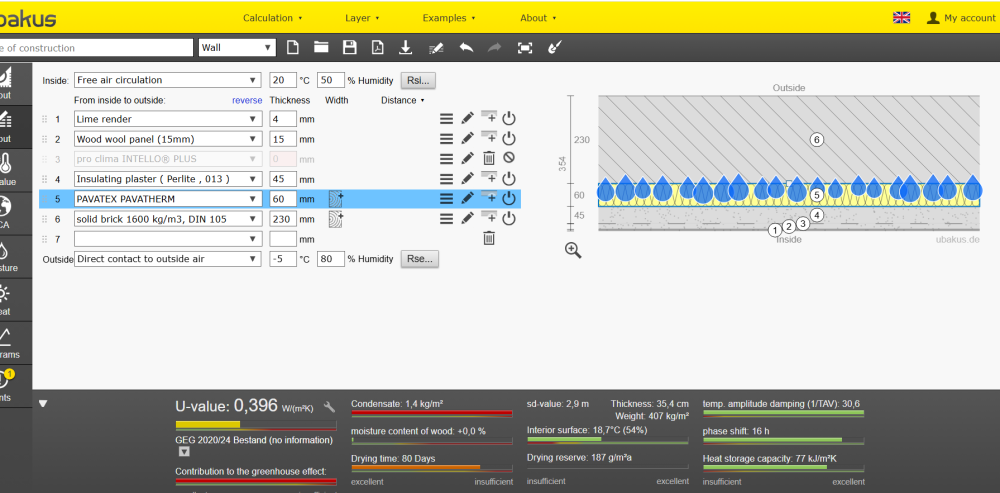

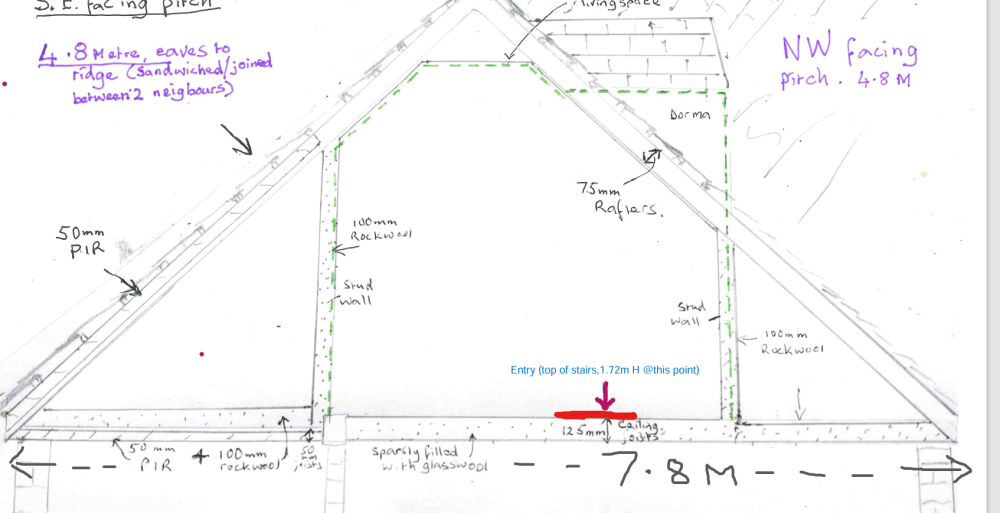

Thanks yet again @Redbeard for your latest suggestions & indeed I hadn't thought of this 'tunnel', & if I decide I can 'live with it' + convince B.C. this could be a way to avoid expense of raising the roof / insulation height. I attach the diagram again but with various additional measurements. Of course I could also add substatial amounts more insulation to those voids in both eaves, to (hopefully) create a much improved U-value & to compensate for deficiency elsewhere (though perhaps never able to get sufficient in) as you yourself mentioned a while back, as well as the 75 + 25 PIR you mention in yr prior post. If anyone knows how to calculate a u-value for these 2 'triangular voids' in Ubacus etc (filling up with rockwool perhaps) could be helpful. Your 'tips' too about a SAP & a greater than 15yr payback period 'excuse' noted; then also your tips re materials for the box gutter construction sound helpful, thanks. This box gutter would be very much for a specialist to do, if I go that direction.

- 9 replies

-

- heat insulation

- regs

-

(and 2 more)

Tagged with:

-

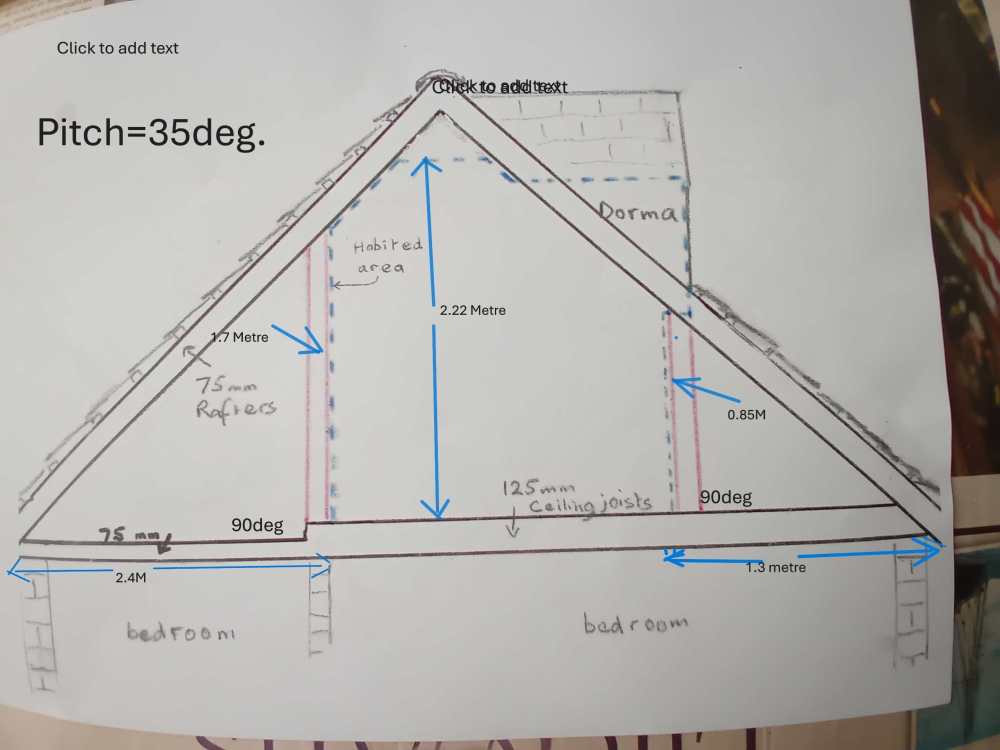

Many thanks @Redbeard, also @Iceverge for your constructive suggestions. These have helped me focus harder on the project, the only major refurb of my 36 yrs in the house - to put slates back on this 1897 terrace after previous owner opted for a cheapo cement tile job - & with no insulation. And its the upgrading of the roof thermal element which will require technical ingenuity & thank you for your already helpful advises etc. Currently I'm awaiting BC considering dispensation allow me a lesser U value in roof thermal element, in light of a low attic ceiling, as in reality it prevents my insulating under it, although, the only other place I could then put insulation is within the 75mm rafters (minus a 50mm air gap !). Instead therefore, I DO HAVE TO seriously consider raising the roof & fitting upto say 5" of insulation there (& making a warm/hybrid roof). Thus planning permission would be sought & I may have to bear with neighbours objections & some significant uplift in project cost. But this increasingly looks the only realistic option, + would make for a thermally more efficient house. And, I've begun looking closely at the type of 'bonding gutter' I'll need at junction with neighbours roof (one side). A chat with a 'lead fabricator' / supplier has recommended a box gutter instead. Photos below are:- 1, my current roof 'junction' (with neighbour); this runs down centre line of chimney. 2, This a perhaps suitable box-gutter design?? I'd much appreciate any views/suggestions from anyone on this aspect of the build. I'd employ a leadworker for such work but any independant views on this detail from forum members welcome, before I commit. Infact I can't find any photos of a box-gutter install on a roof like mine - only pics of where 2 (opposite) pitches meet together. Did the 'lead-worker' mis-advise me? Any thoughts please, appreci\ted !

- 9 replies

-

- heat insulation

- regs

-

(and 2 more)

Tagged with:

-

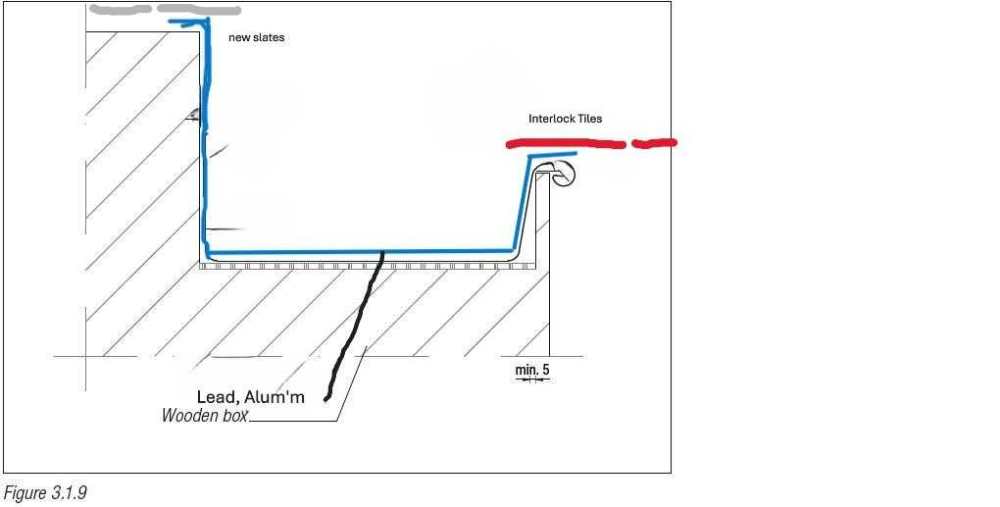

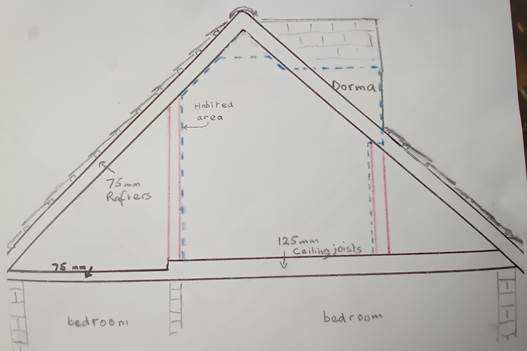

Many thanks@Redbeard your continuing interest in my roof+insulation upgrade. To answer yr Q's of last night hope the following helps: 1st pic is a 'section thru' my current roof as in my prior post but now with measurements. (It does include info too about the insulation currently in there but this likely ripped out during upgrade). And here's a a pic taken from the entry point @ top of stairs: In light of yr suggestions I've made a bit of progress this week & am drafting this right know, so will post this too forthwith

- 9 replies

-

- heat insulation

- regs

-

(and 2 more)

Tagged with:

-

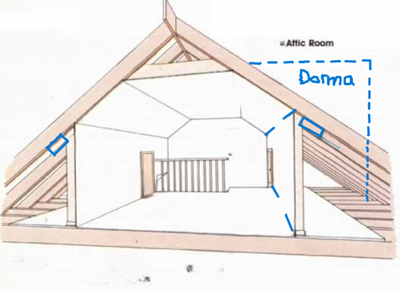

Whilst plans to re-roof my Victorian mid-terrace home back to natural slate isn’t too daunting to do myself, but meeting the regs in upgrading my roof’s thermal element effectively seems to necessitate much expert knowledge – and Building Control state . . I must improve roof insulation (to U = 0.15) as part of this re-roofing project! The manner in which 130 year old properties like mine were built seems to constrain the options for improving this particular insulation element up to current standards:- Essentially, there’s always been a 2nd floor attic space ‘under’ the pitched roof, making a 4th bedroom, but which by its virtue/presence leads to- 1) a low-ish pitched attic bedroom ceiling (only 1.72 metres height at the room entrance) - making it impractical to add additional insulation below ceiling level; 2) 75mm-only depth rafters above the ceiling, limiting insulation within this space; 3) roof tiles (currently 70’s concrete ones) immediately over the rafters & which run through & across on to neighbour’s adjoining terrace as if our 2 roofs are one, probably limiting options at this level too. Its basically a cold roof, currently with limited amounts of mineral wool under the rafters. Also have a NW facing dorma. Continues below --> My property inc.dorma,left, my roof adjoins neighbour to the right, @ mid-centre of chimney Section dagram :- shows- habited area in green, stud dwarf walls in red. Notes: (A) I see one immediate way for some u-value improvement – by ‘over insulating’ outersides of the dwarf walls, ie the 2 eaves (storage areas), compensating for deficits elsewhere. (but likely still insufficient). (B) And/or could I could ask for a dispensation from the regs in light of the already restricted ceiling height inside the room? Also to mention, I’m not in a conservation area, & its not a listed property. I’d also like to prioritise the use of wood fibre/hemp/rockwool rather than PIR, in the upgraded element if possible, being concerned for condensation risk, decrement delay & reducing road noise. All without breaking the bank. In an ideal world all could be achieved by my raising the roof a few inches (perhaps 5”?) then placing mineral wool &/or wood fibre above + within the rafters, ie making a hybrid roof. BUT! – I’d need ‘the mother of all’ bonding gutters where I adjoin my neighbour’s roof [BC officer says it could be done, in lead, ie with a 5” step-up adjoining neighbouring roof] – Is this even pheasible? Also, would I need Planning permission for this 5”uplift ? Raising the roof/adding room for insulation to me seems the only way to get to the U-value requirement. – anyone on the forum know answers to these ideas? . . would be most helpful ! I could pay for advice from an architect/technologist but scared of getting a dud! Thanks.

- 9 replies

-

- heat insulation

- regs

-

(and 2 more)

Tagged with:

-

I plan re-slating the roof (currently large cement tile) on my mid-terrace victorian house & Building Control expect me at the same time to upgrade its thermal-element (insulation!) to meet their latest U-value requirements. I have only 75mm roof rafters; also, my (original,existing) attic room has an already limited height (pitched) ceiling so I'm already close to hitting my head as I enter the room from its stairs. A U-value calculation provided by Proctor Insulation suggests 60mm PIR between rafters then a further 65mm PIR + a VCL in 20mm cavity, ie totalling a basicallyunacceptable additional 85mm on underside of the room's ceiling. Can anyone suggest a way I could avoid my needing so much insulation on the internal side . . preferably without resorting to my having to add insulation above rafter, ie 'raising the roof' ? . . as this would be relatively impractical - since an adjoining neighbour's roof, 1 side, is 'integrated' with mine, our 2 roofs being as one . . . whilst a 'substantial' bonding gutter could be created at the perimeter with my neighbour to accommodate a higher roof/additional insulation, its likely expensive / might incur resistance from neighbour. Continues below: Existing attic room quite like this: Boundry of my roof runs down centre line of chimneys This is the provided U-value calc. :- Name Depth (mm) Layer Thermal Conductivity (W/mK) Layer Thermal Resistance (m2K/W) Bridge Material Bridge Percentage (%) Bridge Thermal Resistance (m2K/W) Layer Vapour Resistivity (MNs/gm) Layer Vapour Resistance (MNs/g) Slates 9 2.198 0.0041 2.5 Unventilated Air Layer - Battens 25 0.1623 Softwood Timber 8.3 0.19 0.05 Proctor Air - draped over rafters. sarking/membrane 0.08 Unventilated Air Layer - Proctor Air draped into rafters 15 0.1623 Softwood Timber 8.3 0.12 0.05 Polyisocyanurate - Between rafters 60 0.022 2.7273 Softwood Timber 8.3 0.46 100 Polyisocyanurate 65 0.022 2.9545 100 Reflectatherm Plus 750 Reflectatherm Cavity (Floors, Roofs) 25 0.4533 Softwood Timber 8.3 0.19 0.05 Plasterboard 12.5 0.21 0.0595 60 Parameter Value Total Thermal Resistance 6.0951 Uncorrected U-value 0.1640 Fixings 0.0016 Air Gaps 0.0017 Total Corrections 0.0033 Corrections Not Applied as ΔU is less than 3% of total U U-value (corrected & rounded) 0.16 Any suggestions & thoughts would be welcome, thanks! I'll further refer to the 2 membranes in the roof build-up, as in the U-value calc. They're Proctor's top range stuff & I plan using them :- The Proctor Air membrane is described as air & vapour pearmeable; their Reflectatherm as vapour & air resistant VCL, no specific ventilation required. The permeability of the Proctor Air membrane perhaps raises the question as to whether the use of PIR, especially as being foil faced, is far less suitable here than say mineral wools, in regard to vapour permeability, since the latter would work well with the permeability of my chosen roof membrane. Any comments regards this welcome too. It would certainly require raising the roof quite an amount, perhaps undesirably so.

- 1 reply

-

- roof

- insulation

-

(and 4 more)

Tagged with:

-

Roof was renewed in the 70's to a cement tile in an all-round poor quality job, now needs doing sympathetically, & back to slate (though possibly with some IN ROOF solar on back elevations). 1. Its a cold roof, see pic 1, showing SE & NE elevations. A main issue is - to up-grade its thermal element extra insulation on interior side of (original) attic room of greater than 40-50mm would be impractical due to already restricted room height & width, see pic 2. So, I'd 'try' adding insulation above rafters, complemented by the PIR between rafters, (& then makes it a hybrid roof, as Redbeard reminded me on here). So I see raising roof height (by say 50mm) basically being essential, to get to regs, & being 'engineered' by way of a counter-batten etc; but its also necessary my roof 'integrates' with my neighbour to the left side (using a bonding gutter of some comprehensive design I guess, though my B.C. officer says such a bonding gutter, & perhaps additional lead flashing(s), no big deal!) I'm still going to struggle to get to a 0.16 U-value however much insulation I can get in/up there but see little other option. (Redbeard also mentions a 2-thirds above/ 1-third below-rafter rule of thumb for insulation to avoid the 'interstatial' enemy). Q) Has anyone else any thoughts / suggestions on my meeting my 0.16 U-value for insulation requirements or even approaching - B.C. look sympathetically at draughty old properties . . they say. 2. I include below a link showing how TLX (gold, a multifoil) suggest their product be used above rafter in build-up of roof thermal element -including a counter-batten, stated as 38mm (old regs?, presumably now 50mm?), & which also provides ventilation on cold-side of roof. And this would raise my roof +/- 50mm). See its detailing & spec. here:- https://tlxinsulation.co.uk/wp-content/uploads/2021/08/TLX-Gold-Counterbattened-plus-50mm-PIR.pdf 3. It says, in this link, that TLX multifoil used to build-up thermal element with this product, including air gap/s, above rafter, followed by 50mm PIR/phenolic within rafter, has a U value of 0.34. So, if I were to indeed add a further 40-50mm max. PIR (thermal conductivity .022 W/mK) to the inside, under plasterboard . . would this 'build-up' get any where near the 0.16 requirement? (its beyond me to calc. this myself!). a) Anyone else care to comment further on my thoughs on this insulation detail? b)also what do you/others REALLY THINK about these multifoils - do they actually work (as long as fitting + air gaps adhered to) . . or not, & actually meet U values claimed? c) Also I'd be interested to hear from anyone about design/detail of a succesful bonding gutter - my roof will be in ~10mm slate but raised say 50mm as explained : meeting neighbour's cement tile. Many thanks, Stephen, Leicester area.

- 2 replies

-

- roofing

- insulation

-

(and 1 more)

Tagged with:

-

I need to re-roof/slate my 'typical' town-terrace property + upgrade its insulation. As a 'hands-on' tradesmam/handyman my work included small roof + gutter repair issues etc; So whilst aware + competant of some of the work & its detailing to meet regs, I need an amount more knowledge to accomplish everything this entails. I plan to be hands-on, assisted by say a roofer/tradesman (retired?) able to work up to the high standard I desire. I think, to obtain the guidance needed I'd best seek some practically orientated on-site advice/consultation, perhaps from a local roofer (retired?) or architect. . . . Can anyone suggest the precise profession/type of person to ask. I DON'T want to be just fed theory - I want practical tips & a site visit or 2. I'm north of Leicester. Info about current roof etc:- Roof renewed in the 70's in cement tile in an all-round poor quality job, now needs doing sympathetically. My finances are limited - I'd input some tools, be hands-on + my limited knowledge; further motivated to keep job in-house as scared of being 'hoodwinked' by a deceitful professional. A bonding gutter will be required where my roof joins neighbour, see left on photo 1. Is a cold roof - but to up-grade its thermal element I'd ideally now add insulation above rafters to the existing between rafters, thus course raising roof height by say 50mm too, but possibly unrealistic! . . as need to integrate with neighbours roof. Adding more insulation within existing attic room impractical as seriously impinges on current limited height/width. Thanks any suggestions.

- 3 replies

-

- insulation

- slating

-

(and 2 more)

Tagged with:

-

Hi, IGP. I came across your recent post & photo just now. I've just joined Buildhub with a question 'Laying hardwood floor over suspended floor joists; would any underlayment help?' Your posts & responders have helped answer my question to an extent, so thanks. I've paid £1700 for new floor planks to cover a room similar size as in yr photo & don't want them to rot, want optimum insulation too. Found the article in the thread - 'Best Practice Approach To Insulating Suspended Timber Floors' really helpful & plan to follow it. Sounds expensive though! I attach a photo showing what I'm doing. Will wrap it with the appropriate membrane(s) but leave the insulation @ current 80mm as concerned to keep the joists breathing in part at least. Got the fireplace & hearth to upgrade too. Cheers, Steve/Neverfinished

-

Hi, I'm about to begin lifting the original 'pine' planks flooring in my victorian terrace home. Then to lay American Ash (19Depth x 138mmWidth) planks, & I could just lay them again straight on the joists as originally. Being on the ground floor, there's the typical 3ft 6in ish 'crawl space' beneath, which has a well designed 'air-draught' thru; And at base just the original reasonably dry soil within brick foundations. See photo attached. I've added 80mm of Celotex between the joists several years ago. Original planks survived fairly well in the environment just described though had cupped, doubtless a long time ago, & had been 'face nailed'; I'm thinking I'd secret nailing this time thru groove in T & G might minimise cuping this time? Would my new floor also benefit from 'shielding' from the elements, especially water vapour, down in that under-space? Perhaps I lay a 6mm plywood base ? &/or lay a Tyveck type breather membrane, on the joists ? I've been a decorating, some carpentry, tradesman for years. I'd much appreciate anybody's ideas / suggestions before I start. Thanks in anticipation !

-

Hi, I'm about to begin lifting the original 'pine' planks flooring in my victorian terrace home. Then to lay American Ash (19Depth x 138mmWidth) planks, & I could just lay them again straight on the joists as originally. Being on the ground floor, there's the typical 3ft 6in ish 'crawl space' beneath, which has a well designed 'air-draught' thru; And at base just the original reasonably dry soil within brick foundations. See photo attached. I've added 80mm of Celotex between the joists several years ago. Original planks survived fairly well in the environment just described though had cupped, doubtless a long time ago, & had been 'face nailed'; I'm thinking I'd secret nailing this time thru groove in T & G might minimise cuping this time? Would my new floor also benefit from 'shielding' from the elements, especially water vapour, down in that under-space? Perhaps I lay a 6mm plywood base ? &/or lay a Tyveck type breather membrane, on the joists ? I've been a decorating, some carpentry, tradesman for years. I'd much appreciate anybody's ideas / suggestions before I start. Thanks in anticipation !