Trojan

Members-

Posts

19 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Trojan's Achievements

Member (3/5)

3

Reputation

-

cable through to exterior- conduit required?

Trojan replied to jpadie's topic in Consumer Units, RCDs, MCBOs

Fitting, end box. Cut a 25mm hole in the back of the end box and screw in the adapter fitting, small section of conduit siliconed in the fitting and push it all through the hole from outside. Silicone round your hole where it comes through the OSB into your cavity. -

cable through to exterior- conduit required?

Trojan replied to jpadie's topic in Consumer Units, RCDs, MCBOs

Twin and earth isn't an exterior rated cable, not a problem if you're running direct through a wall into the fitting (ideally should be sleeved in a conduit but no ones losing sleep over it). Running it outside is a different story though and would need to be in a conduit, PVC would suffice if it's in an area not subject to mechanical damage. 10mm T+E is thick and fairly inflexible, you'd probably want 25mm conduit to pull that through. Any reason you don't want to use armour? -

That is a RCD not a RCBO - it has no overcurrent protection. The more concerning part is that looks like your consumer unit is being fed by what looks to be a 10mm twin and earth with no overcurrent protection (other than main fuse). How far is your CU from this breaker?

-

Positioning new CU, best CU, connecting CU to meter

Trojan replied to Del-inquent's topic in Consumer Units, RCDs, MCBOs

Yeah neither do I tbh. Another issue is that if you're removing the old CU you're potentially taking some/all of those cables out of safe zones. -

Positioning new CU, best CU, connecting CU to meter

Trojan replied to Del-inquent's topic in Consumer Units, RCDs, MCBOs

How old is the wall you want to go into? If it's old breeze blocks then honestly don't bother, if it's newer style concrete blockwork you might get away with it but I wouldn't be confident in saying whether that would be compliant with building regs (at what size does a hole need a lintel etc). Electrical reg wise - as long as it's 50mm from the finished surface of the other side it's ok. -

Probably depends on the model but the ones I was looking at are outdoor unit only with no pump. PUZ-WM50VHA. That's the one you should be looking at as well IMO

-

Positioning new CU, best CU, connecting CU to meter

Trojan replied to Del-inquent's topic in Consumer Units, RCDs, MCBOs

Obviously assuming this is a non load bearing wall. The hager board needs a minimum of 72mm to recess from the finished wall surface. With the 12.5mm plasterboard on each side (+ probably around 10mm each for dot and dab) you'd be right on the limit for being over 50mm from the other side of the wall assuming standard 100mm block. In reality though, good luck chasing a massive hole 50mm out of crumbly block without it falling to bits. Put it in the external wall or make do with a surface mount box. -

Positioning new CU, best CU, connecting CU to meter

Trojan replied to Del-inquent's topic in Consumer Units, RCDs, MCBOs

A bit confused at what you mean, I take it the internal wall you're talking about is perpendicular to the meter box wall? Are you planning to chase the cables into your block wall? If the cable is within safe zone on the external wall it's technically ok, if chasing though it's probably as easy to use SWA, clipping tails direct behind cabinet in zones is also ok. Fused isolator in the meter box is not a requirement if the tails are under 3m but isolator is always nice to have. -

Could you give a clearer picture of how it's plumbed into your system?

-

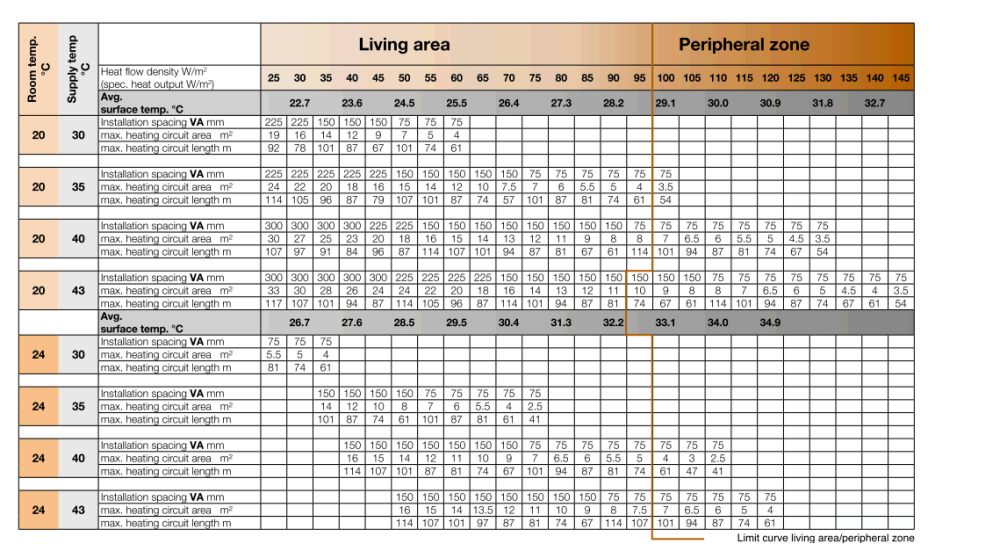

Similar to you badger I'm looking at installing a simple ashp single zone UFH system (although in a much higher heat loss area). This is a performance table I've been looking at to get an idea (they also have performance tables for their different systems and floor coverings, this ones fairly low profile with ceramic tiles - highest output). 4kW at 120m2 works out at 33W/m2. Looking at that 8 loops at 150mm centres would be more than sufficient and you could probably even get away with 6 or 7 at 225 centres while maintaining output at 35 degree flow temps. Looking into calculating flowrates a lot of google sources say 2-3 litres per minute or loop length/40. I watched a video of urban plumbers though where he calculates it by flow rate(l/s) = heat output(kw)/delta T(K) x 4.2 (specific heat capacity of water). Annoyingly his came out at 2.5lpm with a delta t of 7 so I don't know if it's just coincidence that he's in the range everyone else seems to use. If the formula is roughly correct though you'd only need 8 litres per minute (or 1 l/m per loop) for a delta t of 7, and the lower the output required (warmer days), the further that required flowrate falls. I've switched up the formula as I know the range the heat pump wants to operate (7-14l l/m) which would give you a delta T closer to 4 or 5 depending on output needed and flow supplied. I'd also urge you to go for the 5kw ecodan as it will modulate down to sub 2kw in warmer temps. Take everything I say with a pinch of salt though, I've not actually done it yet so it might turn out I'm talking complete pish.

-

He'll just be building the floor up with adhesive I'd assume

-

ASHP with underfloor heating project question

Trojan replied to Trojan's topic in Air Source Heat Pumps (ASHP)

That makes sense, although that will only be at the lowest outside temps. According to the table, those loops will output 60w/M2 at 25 degrees flow temp which takes that down to 260W by your formula. -

ASHP with underfloor heating project question

Trojan replied to Trojan's topic in Air Source Heat Pumps (ASHP)

Cheers, will have a look at that tomorrow. Think it's U value youre taking about but probably not far different, thing I'm looking at says U value - 1.33 or R value - 0.75 I can't imagine why you would need such a high heat output if you had decent insulation so I understand there is going to be heat loss but it's surely still going to be a more efficient and comfortable place to be? I haven't thought about the walls, mainly because the rooms are so small I wouldn't want to compromise with that. -

ASHP with underfloor heating project question

Trojan replied to Trojan's topic in Air Source Heat Pumps (ASHP)

Wouldn't know where to start! The table I'm referring to though is a performance test assuming 0.75R insulation so I take it the 95w/m2 is measured from the floor covering. How can I work out the required flow rate for each loop? A quick google gives a guideline of loop length/40 but that seems overly simplistic? I would have thought the diameter of the pipe would have to be considered. Assuming that's close enough with 10 loops at a maximum length of 61 metres I'd have 15.25 l/s, I think the unit I'm looking at max flow is 14.3 l/s which isn't a million miles away. -

ASHP with underfloor heating project question

Trojan replied to Trojan's topic in Air Source Heat Pumps (ASHP)

Are there small heatpumps with better modulation? Ive had a look at a couple different brands (vaillant and samsung) but definitely been most impressed with the ecodans datasheet. I suppose I could add a DHW tank to sap some of the wasted heat but kind of ruins the simplicity of the plan! Unless my calculations are wrong the polystyrene has an R value of 0.625, coupled with the floorboards under it I'd imagine that'll take it over 0.75 which are the "presumed conditions" for that output.