Dunc

Members-

Posts

184 -

Joined

-

Last visited

Everything posted by Dunc

-

I need to have a couple of penetrations in my timber cladding to allow ASHP pipe and electric connections. Any suggestions for a tidy way to finish these? For the MVHR it's been easy as the ducts terminate with a flanged louvre grille, covering the rough cut and allowing a good squidge of sealant. How to achieve a tidy finish around pipes and cables and seal the edges of the hole? Better to put a single large duct in and put all the pipes and wires through this but then how to make airtight inside and water & bug proof outside? Better to do each individually?

-

Fire proofing cable penetrations.

Dunc replied to Russell griffiths's topic in General Self Build & DIY Discussion

Dunno if this applies for you: Scottish building standards technical handbook section 2.1.14 allows penetrations of up to 40mm diameter without remedial measures. -

I installed an external type door between the garage and house on the basis that its insulative properties and seals would likely be as good as the house's front door. GRP, solid core, FD30, SBD, self closer supplied. Just asked them to not fit the letterbox or knocker. Available online from various suppliers, manufacturered by Unity. Self install was pretty straightforward. Unless you're aiming for Passive house certification I suspect it'll only be a minor component of the overall structure's performance. Will be interesting to see if I can persuade the air tightness tester to do 2 tests, one via the hose door and one via the garage door.

-

I had a consultation/planning session with Velux directly (its a free service) and they produced a detailed quote including all part numbers for the various insulation and flashing kits as well as links to installation instructions. The list price was eye watering and they advised me to take the quote to my preferred supplier who would offer discount it. My local builders merchant beat all the internet prices by a good margin.

-

I have some small aluminium sheets 2mm thick about 200mm x 75mm. I want to make it into an L-shape with the bend paralell to the long side and the tail being about 20mm (to make a cosmetic capping for a couple of corners). Any tips and tricks? An initial attempt with the sheet clamped to a bit of 2x4 required a mallet to bend it - I'm not strong enough to make it bend by hand. The radius is a little large, but acceptable. However it's difficult to create a flat surface having battered it with a mallet - there are a few bulges where it doesn't sit quite flat.

-

Fire Stop Locations for Timber frame with external cladding

Dunc replied to HanleeHouse's topic in Timber Frame

Worrying on the wasps @saveasteading. The plastic eaves vents I have are about a 3-4mm gap. Given they're sold as eaves vents I'd rather hoped they were fit for purpose in keeping unwanted beasties out. Now feeling paranoid that they may not do the job! Having said that, round here I'm much more concerned about rodents and weasels which we know nest in the neigbours' lofts than insects: not much will keep out the midgies 🤣. Problem is as the weave of the mesh reduces so does the air flow. -

Fire Stop Locations for Timber frame with external cladding

Dunc replied to HanleeHouse's topic in Timber Frame

I have plastic eaves vents to go ontop of the fascia board. At cladding voids (bottom of the cladding, top & bottom of windows, verges, anywhere a mouse could think looks interesting) I'm using stainless steel woven mesh, 8 count. 150mm x15m rolls from Robinson Wire Cloth were the cheapest I could find, even with a surcharge for delivery to Scotland. Listed as "rodent mesh". Wear gloves, cut to size with tin snips, bend to shape by hand no problem, fix with button head stainless screws or just trap behind battens, as appropriate. I must have got through 150m of the stuff and I'm still not done. You definitely need mesh! How this partridge thought it would squeeze up a 50mm gap is beyond me....I shall be re-prioritizing getting the eves vents sorted 🙄 -

Fire Stop Locations for Timber frame with external cladding

Dunc replied to HanleeHouse's topic in Timber Frame

Timber for vertical. CV strip was the least expensive intumescent that I found for horizontal. Good service from lifeline fire protection who advised on which size product to use. -

Fire Stop Locations for Timber frame with external cladding

Dunc replied to HanleeHouse's topic in Timber Frame

I just said: This is my proposal for fire stopping. Are you happy? They said "nearly" just don't forget the eaves. simples. -

Fire Stop Locations for Timber frame with external cladding

Dunc replied to HanleeHouse's topic in Timber Frame

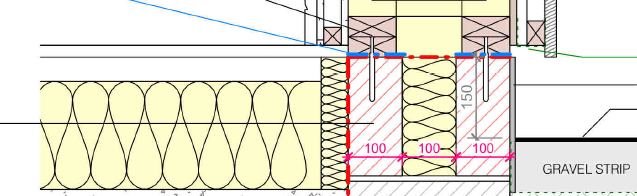

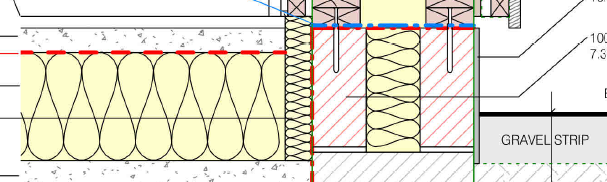

I ended up just putting a proposal to my BCO and asking if they were happy. They required horizontal fire stops (intumescent strips) between floors (though couldn't specify if this should be at ceiling plasterboard level, or at upper floor level), at the eaves, and above/below windows/doors -

+1. I'm about to do this on my MBC larsen truss frame, though I don't have any inner lining (ply or plasterboard to worry about) and it's before the cellulose fill. I sourced some very cheap 600mm long auger bits from Amazon and intend to use a jigsaw. Just need to buy a couple of airtight grommet/patch things to slide over the duct to provide a seal against the propassive board. I'm curious how easy (or otherwise) it will be to push the duct through, or dig through, the insulation if its installed before you put the ducts in. There is an old thread where @Jeremy Harris described putting a small (~30mm) duct through his (similar construction) wall after insulation. My recollection is he described it as quite tight, but I can't find the thread now.

-

DPM External Flap - what to do with it?

Dunc replied to AppleDown's topic in General Construction Issues

+1 to lapping down. Our breather membrane is not 100% watertight. If I'd lapped up behind it it the dpm could have collected the small amounts of water that sometimes penetrate in high winds (no cladding yet). Trimmed DPM off about 50mm below sole plate. Left the breather membremane long enough to cover this. Used the stainless steel mesh that is at the base of the cladding battens to stop it flapping about. -

Masons mitre or butt joint for solid wood joint

Dunc replied to paro's topic in Kitchen Units & Worktops

+1 on butt joints with biscuits (not glued) and 2 or 3 bolts recessed in the underside. Just a bit of CT1/OB1 at the top of the connecting faces before clamping up. Worked fine on my previous kitchen which had 3 joints in oak worktops. Stainless steel screws in slotted brackets to hold it to the wall or units underneath. -

Perimeter insulation - flooring butted up to or laid over?

Dunc replied to Dunc's topic in General Construction Issues

Will have to wait until its all in and get the laser level on it, but looks like +/- 5mm at the moment, so not disastrous! -

Perimeter insulation - flooring butted up to or laid over?

Dunc replied to Dunc's topic in General Construction Issues

I'm well aware of the arguments around thin and thick screeds. There are many excellent discussions on this forum covering the subject. We're going at 50mm (architect was pushing for 40mm!). The PIR is already on site and the first layer (120mm) installed so rightly or wrongly, we're fully committed. I would, in retrospect, have preferred 70mm to allow better tolerance of the uneven slab but we are where we are and I'm sure it'll work out. Everyones thoughts and recommendations have been much appreciated as always! -

Perimeter insulation - flooring butted up to or laid over?

Dunc replied to Dunc's topic in General Construction Issues

@Gus Potter thanks for looking at the other details. The load transfer is on the inner leaf, aparantly. Vertical timber cladding has 20mm vertical battens then 42mm horizontal so there should be plenty ventilation. -

Hopefully a quick one: When installing the PIR floor insulation a 50mm perimeter upstand is specified. In one of the architects diagrams the upstand stops level with the screed and the final floor covering oversails this to butt up aginst the wall. In another diagram the perimeter upstand extends high enough for the floor covering to be separated from the outisde wall. As this is a larsen truss frame, the inner sole plate is effectively insulated from the outside as it doesn't span the full width of the wall. The blockwork underneath the sole plate has a course of Marmox blocks below the top block and this will overlap with the 220mm PIR, so the top block is thermally broken from the ground....so I *think* it's OK to oversail the upstand? Top to bottom: Tiles 50mm screed with UFH. Top of screed is level with the bottom of the sole plate slip membrane 220mm PIR 150mm reinforced slab.

-

Ground floor shower tray support over insulation

Dunc replied to Dunc's topic in Bathrooms, Ensuites & Wetrooms

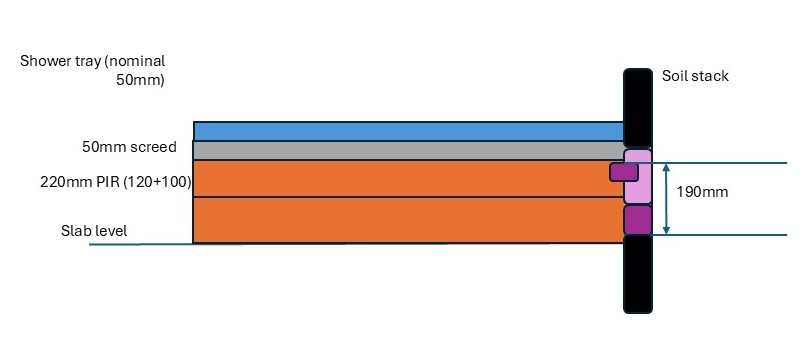

@Nickfromwales huge thanks for the detailed decription! Screed in the next couple of weeks but shower tray not for months; just want to make sure I don't do something now that I regret later. Rest of first fix is coming down from above so no problems there, ta. Are the concrete screws those black ones horizontally through the blue expansion skirt? In my case the shower will be going in against 2 walls and I'll need to build a third stud wall to separate the soil stack (green line). I was going to shutter off along the edge of the shower tray +50mm. (Only 1 of the 2 layers of PIR is down on the floor in this photo. Next set to go in with staggered joints). So you suggest that this would be fine with just the PIR and self leveling compound topped with flexible tile adhesive - what relative depths? I have 50mm to make up. Given we haven't decided on a tray yet, I am wondering whether leaving out the PIR in this area would be wiser to allow better access for installing the waste, rather than digging it out later. If so, are you suggesting that laying the tray on the added-back-in PIR plus tile adhesive is NOT appropriate in this case? The other "exciting" challenge is that will I have to connnect the 50mm shower waste to the soil stack which is currently just that stub in the top right hand corner. A female/female straight coupler and a boss adapter (such as https://www.screwfix.com/p/floplast-push-fit-3-boss-single-socket-pipe-black-110mm/97309) puts the top of the 50mm boss at 190mm above the bottom of the coupler. With my 220mm PIR + 50mm screed the bottom of my shower tray is 270mm above the slab so I've got 80mm to play with. Even with a shallow waste, say the Macalpine 53mm (https://mcalpineplumbing.com/traps/shower-traps-accessories/90mm-shallow-shower-trap-53mm-high/) and assuming a drain in the long-side of the 1700mm tray (i.e. 1m from the stack) I'd need about 18mm fall so I'd be cutting the stub off with the coupler stopping only 20mm above slab level. Feels tight! Solvent weld boss adaptor may be better here, assuming solvent weld is OK on the brown underground type pipe? But obviously comes with its own risks - one shot to get it right. Any other suggestions? -

Ground floor shower tray support over insulation

Dunc replied to Dunc's topic in Bathrooms, Ensuites & Wetrooms

That was my concern. I initially thought to construct a wooden frame topped with 22mm ply to support the tray from the slab and then stuff insulation underneath. However, the rest of the ground floor is basically 50mm screed (i.e. a mortar-like substance) on the same insulation. So the question could equally be asked: What happens when you sit on a chair? Does the floor dip under the chair legs? Thus the lazy side of me got to thinking could I save a bit of woodwork... It's rather an expensive experiment to give it a go so I thought it best to ask: I'm sure those with KNOWLEDGE (@Nickfromwales) will be along to put me right. -

I will be installing a shower tray on the ground floor. Build up is: 150mm slab 220mm PIR (don't ask - it was supposed to be 300mm EPS but various architectural and construction cockups and this is where we are) Slip membrane 50mm screed. I'll shutter off the entire shower tray area before the screeding is done (because SWMBO hasn't finalised a desicion on which shower tray so I don't know where the waste will go). Is it reasonable to just lay the tray on a 50mm bed of mortar straight on the membrane & PIR? Could I get away with a thinner mortar bed (if so how thin?) to drop the tray closer to tile level?

-

Well done on a big step! Best thing that happened on our site was putting down a good layer of MOT1 to control the mud. Thought it might have been an "unnecessary" expense at the time but very glad our groundworker did it. I never got round to building a porch for the caravan and TBH don't miss it as much as I'd expected to, though I appreciate many others have done a porch and found it useful.

-

Problem is I have no way to know what they used and they have no inclination to be specific (unfortunately they've already been paid). "We've been doing this 19 years and never had a complaint" type of response. The adhesive seems extremely strong so I'm concerned that ripping it out might not go well... It was selected because I have a timber frame with cellulose fill so it would be advantageous to ensure any moisture that gets in can escape. Certainly the window is sealed inside with airtight tape and the void filled with foam so the cold bridge is dealt with and the internal vapour barrier is as good as anywhere else in the structure. It does seem to have occured only with very strong wind-driven rain. There has been plenty of more "normal" rain which hasn't been a problem so perhaps addition of the cladding will suffice. I have added some temporary OSB "cladding" to see how that goes. Just need another Scottish Hoolie to try it out. Terrifying to think that if this had been done over summer the cellulose fill would already have been pumped in and I'd never have known until it rotted. Maybe being way behind schedule has some silver linings 🙄

-

Ah. No idea what brand or dimension was used. Definitely soft and squishy Sounds like it needs replacing.

-

As title, really. Is Compriband supposed to be 100% (for want of a better term) waterproof? Does it need anything like silicone in addition? My windows are fitted with a ribbon of Compriband to seal against the reveal at the outside. This is in a timber frame, with the window set back 90mm back from the face of the kit. I dont have the timber cladding in place around all of them yet. After yesterday's fierce winds and pretty much 24hrs of rain I have water running in at one of the windows. The windward side Compriband is sopping wet; water can be squeezed out when puching it with a finger tip. I can't see the back of it as the airtightness membremane is already in place on the inside, but this makes me wonder if this is how the water got in. Rather concerned to have to rely on the cladding and reveal boards for waterproofness!

-

Soil stack to male stub - double femal connector OK?

Dunc replied to Dunc's topic in Waste & Sewerage

Thanks guys. I do appreciate the moral support (i.e. pull up your big boy pants and get on with it) @Oz07 😀 Having said that, the solvent weld option looks less risky. Inspection of the pushfit does show that the downstream male end will simply be in the center of the fitting against the small stop tab, but there is no lip so nothing but air pressure preventing contents sliding down the outside of the male pipe's chamfer. Unless I'm mistaken, the caps that the groundworks guys left are a single piece. Will have another look at them though, thanks @Onoff The bend at the bottom is under the MOT and slab so well beyond my ability to inspect it 20 times a day like I do with most of my other "worry-it-might-not-be-tight-enough" jobs 🤣