-

Posts

696 -

Joined

-

Last visited

-

Days Won

1

oranjeboom last won the day on July 22 2016

oranjeboom had the most liked content!

Personal Information

-

Location

Kent

Recent Profile Visitors

6240 profile views

oranjeboom's Achievements

Regular Member (4/5)

123

Reputation

-

BANG!!! There goes another Sunamp....(number 2 for me....)

oranjeboom replied to oranjeboom's topic in Energy Storage

Just to close the loop on my situation last year. Sunamp arranged for a local contracted engineer to come out to pull out the faulty unit. Same day, a new unit arrived and plumbed into my new ASHP arrangement. So satisfied with the service that I received and hopeful that the new unit behaves. I also made the decision that the other (working unit) wasn't required in my setup any longer (just me and the daughter here now) so decided to sell this....it's listed here on BH, if anyone is interested. Seen very few cycles, so may be of interest to someone. Not sure if the warranty can be passed on though. -

Identify the Swedish screw (and where can I source it?)

oranjeboom replied to oranjeboom's topic in General Joinery

Haha....the board of experts never fails! Bunch of screw-heads!! Thanks for all the responses on my bolt/screw issue! Very close indeed! I'll contact them and see what they can do! Thanks very much! Will need a part number to order or a visit to them to show what I need...but yeah, had not thought about that little Ikea outfit... Ahhh....perfect! That looks like the one.... will try them if all UK options dry up! -

Identify the Swedish screw (and where can I source it?)

oranjeboom posted a topic in General Joinery

So I've started installing my staircase only to find I am one wooden screw short. Supplier of the staircase kit was from Sweden and that was a few years ago. Was hoping to find a quick UK solution to source the screw from. The screw joins secures the balustrade to the main post at the top of the stairs. It's all pre-drilled and therefore has a specific helical screw size and pattern that the screw gets tightened into, so I can't just use any helical size. I've tried doing an image search with few accurate results. What specialist wood fixing businesses are there I can try? I suspect I'll have to go back to the Swedish supplier.... -

So, there's a building site up the road from me where they 70+ house are having beam and block floors installed and using EPS as filler between the beams and again on top before a cement screed goes over. So there are mountains of the EPS offcuts that have all been bagged up awaiting for collection (Landfill, 'recycling'?). As this is high density EPS I was pondering whether it would be a suitable option for me to utilise these offcuts for my EWI project? The offcuts appear to be pretty large (at least 500-700mm in size and possibly 200mm thickness. It may take me a bit longer in terms of trimming them square and I will end up using more mechanical fixtures but seems to be a green alternative for me to save them going to landfill or 'recycling'.... Is this a bad idea? I'll end up with more joins so will that increase the chances of cracking over time? I'll be using mesh and some poly render.

-

Update: Now divorced!😑 But still European!👍

-

...well not quite a bang....more of an ooooooooooooooze of PCM! So I've not been on here for a while....but it's the first thing I did when I discovered this today: Luckily I placed the bugger on wheels so getting it out won't be that hard, but what a poor display for Sunamp. Appears many have gone down this leaky path. Actually, it's my 2nd unit to leak!! My first unit started leaking whilst it was standing waiting to be installed!! This unit has seen service from Oct 2020...under 6yrs! Not sure whether it's overheated or it's come down to a pressure issue. I have expansion vessel, PRV and water softener fitted... I'd decided via ebuild many years ago that the Sunamp was the way to go. I blame Jeremy and co for that!! Hopefully Sunamp will honour the warranty here also. Do we have a death tally for Sunamps on here? I see Mr Harris also returned here due to his unit's death!

-

Just resurrecting this thread... Has anyone tried some of the clamp-style/clip on meters? I now have a heat-pump installed so keeping a closer eye on every day usage and rather than poking my head round to look at the analogue meter (and doing the calcs) it would be easier to have some display to refer to. I do also have solar panels so wary that some meters don't take that into account. I did spot a few on Ali B that work supposedly with grid-feed setups (I.e. PV): https://www.aliexpress.com/item/1005007929330294.html?spm=a2g0o.detail.pcDetailTopMoreOtherSeller.14.6a7fxLONxLONPh&gps-id=pcDetailTopMoreOtherSeller&scm=1007.40050.354490.0&scm_id=1007.40050.354490.0&scm-url=1007.40050.354490.0&pvid=9b0c87e8-0bb5-485e-9615-35783977629b&_t=gps-id:pcDetailTopMoreOtherSeller,scm-url:1007.40050.354490.0,pvid:9b0c87e8-0bb5-485e-9615-35783977629b,tpp_buckets:668%232846%238115%232000&isseo=y&pdp_ext_f={"order"%3A"376"%2C"eval"%3A"1"%2C"sceneId"%3A"30050"}&pdp_npi=4%40dis!GBP!12.23!9.20!!!107.28!80.72!%40211b876717393183553854108ea2f8!12000042902351618!rec!UK!!ABX&utparam-url=scene%3ApcDetailTopMoreOtherSeller|query_from%3A

-

So I started staircase a while back with stringer affixed to wall already. I now want to get the bloody thing done. Just wondering whether I should screw and glue all treads into the stringers. At the end of the day I hate to hear any squeek and want to mitigate the chances of that. So far: Treads not in securely yet.....there's two screws for each tread (underneath into stringer). And this is the overall construct (different design though): I was thinking gorilla glue, or should I stick with PVA? Any other tips? Thanks in advance

-

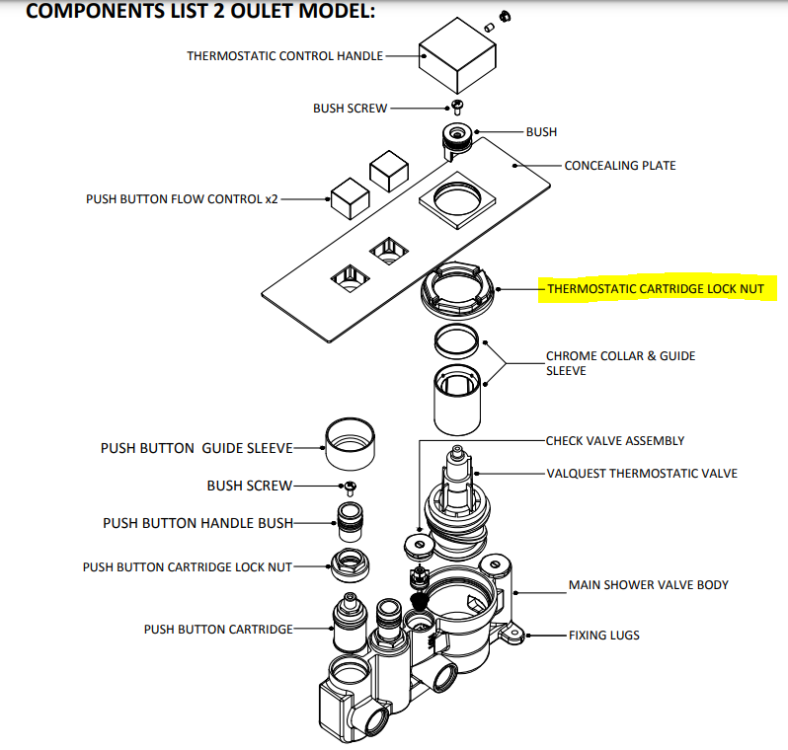

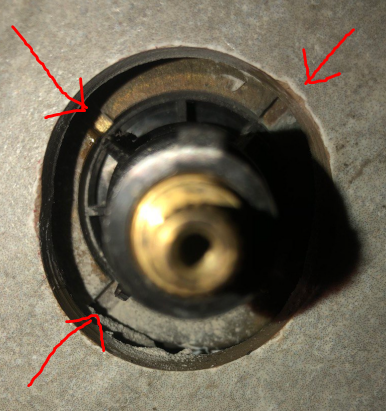

So after 5 years use, the water's luke warm in the shower and all other outlets are bloody hot. I've got a water softener too, so it's annoying that the valve has still buggered up. It's a Hudson Reed unit and I know that the valve is this one: https://www.divapor.com/spares/showers/thermostatic-cartridge/sc50t20-crosswater-thermostatic-cartridge-valquest-sc50-t20-and-sc50t20-m.php?gad_source=1&gclid=Cj0KCQjw-uK0BhC0ARIsANQtgGMIRbE611NVsfsByzD4XmXFkvYy08D1bFRQCgdIYfe25_D5WMzCvjwaArD1EALw_wcB The issue is that the tiling is very tight and I'm hoping that there's enough space to get something in there to dislodge the ring (see below). Due to the depth of the ring behind the tiles (2-3cm) I can't get the angle right for a screwdriver and light hammer tap. Is there a special tool for this job? I've contacted the manufacturer and they're telling me a spanner should do the job....how you're supposed to get a spanner in there I don;t know! Thanks in advance!

-

Trench for ASHP pipework, electricals - tips?

oranjeboom replied to oranjeboom's topic in Air Source Heat Pumps (ASHP)

Thanks ! I think I may recall reading about your DIY approach on here some time ago, but do you have a link to that post by chance? I'm hopeful that installer is supplying my insulated pipe as I've seen the crazy costings! -

So after much faffing around with suppliers, Ofgem and installer, it looks as though I now have a date for my heat pump install (Vaillant Arotherm Plus). Now looking to prepare for the install so looking to dig a trench to determined ASHP location and shortest route to house. Due to the nature of driveway (just to left of hedge, see below) and the line of sight from the gate, the best place visually is indicated by spade). As it'll create a bit of an eyesore and also being adjacent to front door, locating it right next to house is not possible, so I will locate it 9m from the nearest entry point (see rough tape measure line below). Pipework will then go up the wall 2.4m.. through soffit, into loft...1m along the insulated loft...then down through ceiling and into plan room (another 3m), so approx 15.5m in total. The exterior wall is still to be covered by EWI at some point in future so that will cover all wiring and pipework. So, I have a few questions: How deep should trench be dug? 500mm? Armoured cable necessary or can I just use standard cable in conduit I just bury it below the pipework with warning tape over the top? Obviously heat loss is an issue so wanting to minimise that if I can, so I was going to lay the insulated pipework ontop of some EPS leftovers and add some expanding foam prior to filling in - worth it? Any other ideas? Thanks in advance