Nelliekins

Members-

Posts

157 -

Joined

-

Last visited

-

Days Won

3

Everything posted by Nelliekins

-

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

Filter replaced every year, but only because of a note on the calendar. No noticeable issues with flow or water quality from the boiling water. Tap itself gets cleaned maybe once a month, never noticed any scale on the end. -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

Hah, we have a boiling water tap, no kettle! 😂 -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

The statement from UU is that "the water supply to this area can vary in hardness from soft to slightly hard". That seems a total cop-out to me. But Worthington Lakes are literally 2 miles from our house (we are south of Chorley on the border with Greater Manchester) so there is every chance our village gets water from there. And the water there is definitely soft. I might just get it tested, though, to be on the safe side! -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

That's the weird thing - our water is not that hard. I previously misread this information, and reported the Clarke value as PPM - it's actually 75ppm, which is still relatively low IIRC. Circulating pump is coming out this afternoon to be inspected / cleaned. -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

Frankly at this point, the £3k outlay is becoming attractive. Showering in water that is less than 35C isn't pleasant to me. @PeterW and others - can I ask a few questions, to make sure i haven't misunderstood stuff along the way... 1. Should a 30kW system boiler be capable of replenishing the heat in the cylinder as fast as a single shower (@10 litres/min) can deplete it? 2. Should a 100kW PHE be able to heat the incoming cold mains to 50C at 10 litres/min, if it has sufficient supply of hot(ter) water to pass through it on the primary side? If the answers to both the above are YES, then 3. if we switch to using the Willis heaters for the UFH, could we reuse the indirect coil in the cylinder as a DHW preheat coil, to reduce the risk of cold showers happening again? (I am assuming that this mitigates the impact of reduced flow on the PHE primary because the uplift on the incoming mains is already reduced) -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

That was the amount recommended (and indeed supplied) by the plumber who did the boiler side of the system, based on size of the cylinder, the header tank, and the pipework. But clearly not even close to enough... Even the instructions on the Sentinel X100 say 1%, and the system is somewhere around 200 litres. What are the odds that the level of scaling has completely killed the PHE? Am I better off replacing the whole lot, given I am disconnecting the UFH from it all anyway? -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

Ok so there is some extensive scaling inside the pipework. Given there was 1 litre of inhibitor in the water, I am not entirely sure how or why it is this bad after a little over 2 years... Is it possible that the cylinder was too hot at some point and this is the result of kettling? This elbow was between the PHE and the cylinder, so I am expecting this throughout now... -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

I haven't removed the PHE - that's next on my list. But it's the PHE itself dropping in temp very rapidly, which suggests restricted flow rate through on the primary side. The TMV appears to be operating as expected, because if I increase the temperature on it, I can get absurdly hot (>60C) water at a tap for a few seconds before everything goes cold again. -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

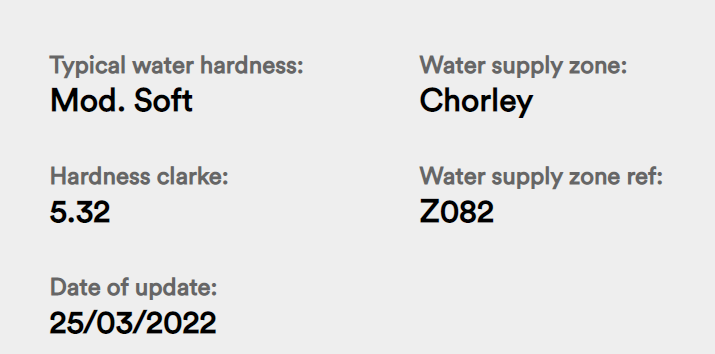

Not hard water - "moderately soft" according to United Utilities (5.32ppm on last check for our area, which was apparently 1 week ago today). We aren't using a water softener. -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

This is probably a silly question... If I am switching to using Willis heaters for the UFH side of things, is there any reason I can't try using the indirect coil for preheat of DHW? -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

Yes, why do you ask? -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

The stats are set at 50°C and 70°C. The immersion is set to 70°C and every time the solar diverter fires up to try and heat the cylinder, it tells me the cylinder is already hot. Yes, flow switch works as expected. Temps going in must be right, because the cylinder stats all say they are. Stats are operating correctly. The temp coming from the taps reaches design temp of 45°C within seconds (which means ~50°C at PHE as expected), but drops off rapidly (within 60s it is below 25°C). This is only slightly mitigated through reduction of HW flow rate. -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

Here is a sketch of the hot water and heating system, please ignore the green link - that's how it was originally plumbed, but I have since remade as per the drawing. The immersion heater is in the top of the cylinder, though. DHW Design - draft 1.pdf -

DIY hot water system needs replacing - Sunamp?

Nelliekins replied to Nelliekins's topic in Boilers & Hot Water Tanks

I even bypassed the flow switch at first and set the pump to "always on" as an experiment (in case the PHE was getting cold too quickly). Pump seemed to run fine, but PHE still goes ice cold within a minute. Flow switch fires as soon as a hot tap opens. I will remove the pump and check that there is nothing reducing flow internally - I even found the handle for the gate valves the other day, so that shouldn't take long. Clearly, if the cylinder is hot enough (70°C), then: 1. The PHE isn't getting enough flow from the cylinder, or 2. The PHE isn't operating correctly, or 3. The blending valve isn't working as it should @PeterW the current cylinder is vented, with an 18 gallon header tank. Any reason to switch to a UVC? And last time I was on this forum, the Sunamp appeared to be almost the Holy Grail - what have I missed? Thanks! -

So... a couple of years ago, following advice from various sage individuals in these parts, I built my own "DIY thermal store" to provide hot water (and a heat buffer for the 250m2 of UFH). For the first year, it worked pretty well, but it's become less and less effective over the past year. Now, the hot water doesn't work at all. I have a 140 litre RM Aquastel cylinder, with dual stats (half way up, and at the bottom). It is heated by a 30kW Worcester Bosch system boiler (with the stats providing for a single long burn), and has a 2.8kW immersion heater powered by the solar diverter (which never fires - the cylinder is always hot when it tries). A single indirect coil in the cylinder provides heat for the UFH. We are perfectly happy with the heating side of things, but the heating requirement is so low that I am intending to use a couple of Willis heaters powered by our Solar diverter for the few days of the year it is required (heating hasn't been on once since middle of February, and was turned on less than 60 days in total last year). On the hot water side, I have what is normally the direct connection to the tank being pumped through a 100kW PHE, with the second side of the PHE being fed by mains cold. The water gets hot for maybe 45 seconds, and then goes (and stays) cold. SWMBO has had enough (and to be fair, I really don't blame her). I don't understand why it is so much worse than it was 2 years ago (when it worked perfectly well for 3-4 showers back to back without a hiccup), but I don't have the energy left to try and solve it. The cylinder is being kept at approx 70C, but the PHE temperature drops rapidly from the incoming cold mains and never recovers. So, as per the title, I am considering either (a) replacing our gas boiler and cylinder with a Sunamp, or (b) adopting a KISS approach and converting what we have into a "traditional" hot water cylinder (i.e. remove the PHE entirely, connect the boiler to the coil connection on the cylinder, and have the contents of the cylinder as the actual hot water that comes out of the taps). (a) seems a more appropriate long-term solution (since gas boilers are so 20th century now, and gas is probably going to skyrocket over the coming years). However, there is a large capital outlay on the Sunamp (£3-4k for the biggest models, plus installation etc). Plus, if we go the Sunamp route, there are a couple of questions that spring to mind: If we are thinking of getting a monobloc ASHP in due course, are we better off getting the correct Sunamp model (e.g. Sunamp Thermino 300 hp-SG) now? If we get the HP model, do we need to install the ASHP from day 1, or can the Sunamp HP models work with just electric heating as well? The KISS approach (b) would probably entail replacing the cylinder (since it has has primary circuit water in it for 2+ years, so inhibitor and whatever else inside it, and I don't know if I would trust just flushing it out a few times to make the water safe). But other to that, it's a bag of elbows and tee fittings and a bit of copper pipe, and I would be done... Help! 😢

-

ICF's soaking up the plasticizer

Nelliekins replied to magnethead's topic in Insulated Concrete Formwork (ICF)

Totally agree. I chose to chase out the EPS with a DIY hot knife and use 6242B cable, derating sufficiently according to 17th edition (which was in effect when my cabling install was designed). I have since been told by the sparky who fitted our solar panels that he'd have put electrical conduit in, so that seems like the "Pro" solution. ? -

ICF's soaking up the plasticizer

Nelliekins replied to magnethead's topic in Insulated Concrete Formwork (ICF)

@scottishjohn if you look carefully you will see there is 50x50 trunking already installed all around the cabinet. Where it's needed I have installed it. As for running cable in conduit, you still have to put the conduit somewhere. If that "somewhere" is in the EPS then it will still derate the cable, albeit not quite as badly. From recollection (I don't have the 7671 guide at home, cos it's living at site at the mo) clipped direct gives 27A limit, in conduit in EPS would give 18.5A or thereabouts (although some argue that the derating isn't valid if you're talking about conduit that is also touching the plasterboard, the regs don't give a firm steer either way so I play safe). Besides which, the lifetime of the mains cable for sockets (which is all that I am chasing into the EPS anyway) is probably longer than my remaining years on this planet, and sockets don't tend to need additional cables pulled ? -

Three pours down..none to go - thank goodness

Nelliekins commented on Simon R's blog entry in South coast ICF build

Lol, we had an excess delivered, and I said to the concrete truck driver "just hold off on tipping all of it into the pump while I check with the crew if its needed"... ... But the driver decided to dump it all in the pump hopper as quick as he could, and chuffed off back to the batching plant. Here's a recent pic of the front of our house... The observant among you will notice something that looks remarkably like a scene from "The Lion King" to the left of the picture. We call it "the Monolith". The 13T digger we had on site couldn't move it, so we have decided to make it a feature! 1/3T pump line, pah! Try 3m3 of C68 concrete being dumped where you wanted a lawn! ? -

Apologies for the lack of updates on the blog. Things have been quite taxing over the past couple of months, coming to terms with my Dad's unexpected passing. I have struggled to find my feet, and to get anchored in the present again. My beautiful wife Kim and my (mental) kids have been amazing, and I think that I am ready to carry on in earnest. Long story short, I am getting my mojo back a bit now, so expect a big update in the next 48h - there might even be a bit of skin on show! ?

- 1 comment

-

- 10

-

-

-

ICF's soaking up the plasticizer

Nelliekins replied to magnethead's topic in Insulated Concrete Formwork (ICF)

We have approx 1200m of LSZH twin and earth installed in our ICF build. Costs a chunk extra, to be sure - first, because its roughly 30% more expensive to buy 6242b cable than the same thickness of the usual grey 6242y cable; second because you're embedding the cable in insulation, you have to derate the cable. That means you end up running radials and rings in 4mm2 cable instead of 2.5mm2. Here's an idea of the hell I am in with cabling... That will one day be a home automation system, with DMX controlled lighting and power circuits, and either Loxone or Unipi managing it all. For now, it's just my nightmare that comes true every time I visit site. ? -

JUB ICF block system - first build experience

Nelliekins replied to Simon R's topic in Insulated Concrete Formwork (ICF)

One question - are the blocks sized off of metric or imperial measures? In particular, the spacing of the webs in my Logix build has been a complete ache of the dangles. You end up either using grab adhesive at the edge of plasterboards or having stacks of 185mm rips taken off your boards because the plasterboard is 1200mm wide and the Web spacings are 8" (203mm). Blooming annoying, especially since you can't just stick plasterboard offcuts in general rubbish! ? -

Yep I think so... Unless you have a better idea? In you look back to the early pics, the steel isn't in great condition - grinding off rust for the welding revealed a few pockets of over 3mm depth - not great for steel advertised as "clean"!

-

1. Remove the temp treads (they're just scaffold planks sawn down to fit) 2. Clean up the PFC by wire brushing it and then maybe a coat of red oxide 3. Build the handrail (4x2 timber screwed to the box section steel, plasterboarded on both faces) 4. Tek bolt timbers to the underside of the PFC 5. Fit oak treads and risers (fixed from behind /underneath) 6. Underboard the PFC with plasterboard, finishing flush with the bottom of the handrail 7. Sleep ?

-

OK so a bit further forward today - handrail uprights are fully secured and a temporary handrail attached for safety... Next up are the oak treads and risers, and the full plasterboard handrail / wall.

-

Yeah, but the steel is rusty as anything and I want to cover it underneath... Just found a sawmill all of 2 miles from my house that specialises in oak machining at absurd prices!! An example - 900x240x30mm treads for £8!