magnethead

Members-

Posts

100 -

Joined

-

Last visited

Everything posted by magnethead

-

ICF Roof sealing Strategy

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

Well we're the worst consumers in the world here in Ireland, so it's €300 a tub (basically everything is double or triple the price of anywhere else), in northern Ireland the price is £150 plus VAT, I got it for a £140 and no VAT because the guy had plenty to spare....Special note when using TT, on ICF, it's goes waaaaaay further then the manufacturer says, that's why he got caught with so much extra Something to do with the clean finish on ICF -

ICF Roof sealing Strategy

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

Done -

ICF Roof sealing Strategy

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

@Conor It all comes from the one manufacturer , called Thermohouse, they do the Roof, floors and walls. All the tech details are on their website -

ICF Roof sealing Strategy

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

Tec7 MS Polymer is what the manufacturer recommended.....expensive as hell!! That's the glue gun option. It is hardy stuff, I've used is years ago (6 years) on a cracked concrete window sill and it's still holding strong. I was speaking to the Triton TT rep and he says (as he would) the black stuff has great adhesion to EPS! I saw a whole house covered in it up north I picked up some extra pots from this sound lad! -

ICF Roof sealing Strategy

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

It's the gables where the gap is. -

ICF Roof sealing Strategy

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

Thanks @Russell griffiths , yes the roof panel is 250mm thick, I have lot's of off cuts of the roof material, that's a good idea, I'll see if I can get enough big bits to cram in there. I'm not sure about the longevity of foam, I've seen low quality foam just shrink and fall out of pipes, The foam they were using was called Insta Stick. I've gone around the outside and Tech7/CT1 'd the little cracks where the roof insulation seals with the wall insulation, Top and bottom (Probably overkill but it gives me the warm fuzzy feeling inside) , I'll do the outside once this is sealed. -

Hi There, the Roof has just being put on my building, the builder has managed to sit the roof about 10mm above the side walls, the Top and bottom are squeezed tight. This was to allow him adjustment on the timber Purlins and wallplates. He says foam will fill the 10-15mm gap at the end, that covers the ICF wall, 50mm internal insulation, 150mm concrete and 100mm external insulation. I'd like to get some thoughts from buildhub as opposed to the builder, as I don't think 'Just foam it up' is an airtight strategy I'll have to go over the internal seam with some Liquid membrane like Triton TT or something. Thanks for your thoughts.

-

Hi, I would like to hear your opinions on what way to do the Windows and Door on an ICF house with Stone facing. Here are some examples below. In this example below the windows are kept back behind the 100mm exterior insulation But this leave an EPS reveal!! up above, the EPS is painted with a TT rubberized membrane and the Lintel is powdercoated black. I understand the guy about, he has a 25mm nib all around the reveal to which the window frame is bonded too, but I believe it won't look the best. I was thinking to bring the stone into the reveal like in the below, but was worried I might not get a good enough seal to the window frame/stone,

-

Is it important to cut into the EPS at an angle above the stopbead? like below I imagine this would be a pain if your stopbead is running up the wall at an angle, i'll be facing the same problem soon enough. It looks like there is some fixing joining the stopbead back to the concrete/block

-

ICF (EPS/XPS) external fixings

magnethead replied to Adam2's topic in Insulated Concrete Formwork (ICF)

Here's some nice fixings, when you want a drainpipe your kid could climb up, These are fixings from Fischer I have seen these used before, they are like LARGE plasterboard screw holders and these are the only houses with external insulation that I have personally seen the drainpipes detach from .... I would be going for concrete everytime, where there is something with any weight hanging off it. -

oh right, I have you, It's all insulation above (ICF blocks) ...so 100mm insulation facing all the way up with a render covering eventually, the upper floor is being built currently.. I arrange to go that way. Thanks

-

Hi, Yes, the 3D shot looks a bit weird above, the Idea is to box it out seamlessly, all in the same render, underneath and on the sides...I literally want to extend the overhang downwards, So insulation shrinks over time, I didn't know that, I guess so does wood, so would little metal legs be the way to go then? Thanks

-

I was just thinking, maybe a 30cm box of insulation hanging below this overhang, would not be structural enough, and might move and crack the render over time? Would you drop some Steel legs off the concrete beams above?

-

Hi There, I need an overhang to drop a Further 300mm from where the poured floor will be. What way would you recommend boxing it out? I got some advise from the builder doing the ICF at the moment to just get some 150mm foam insulation sheets and screw it up to the Floor/concrete above, Does this sound like the way to go, given it's only 300mm. My under side on this overhang will be left at 3M (With concrete beams just inside it's edge - see below)) by the builder and it needs to be at 2.7M Thanks

-

Hi lads, the first few pictures are off my house In Dublin, which is where all the mayhem is, don't confuse that with the later pictures of wiring examples, that is being done by the manufacturers down in Kerry, Ireland. No wiring job on my site unfortunately. I was pissed, all the heads on mine were not braced, will not happen on the next level for sure

-

Thanks Russel, I've no experience with this, just as it all unfolds in front of me panic attacks every 5 minutes. (your calm reply is helping ) It would just be a single length of bullwire, that passes through the insulation and then snipped off when finished, I can't imagine that being much of a thermal bridge, The lads are putting on the floor next week, and I'm going to be all over this from now on. Here's a shot I got from the manufacturer where they braced some of the side wall, for the floor pour. hanging the wire off the internal rebar.

-

Hi, I just put up my ground floor walls, and there's a bit of a belly on one of the walls, where a T wall ran up to it, there was Bracing on one end of it, but not the outside I have since found a solution, but my builder just said 'you learn something new every day'. please see below where the T wall pushed out the exterior wall If anyone can learn, from this, it will be good, the solution is below. Can someone answer who is in the know, Is 15-20mm bow in a wall a SERIOUS problem or not? please I need to know, as the Engineer from the company is coming next Monday, and of course he's going to downplay this.. I'm no expert on this stuff, but it looks like a total cock up on their part. Here is a picture of it THe SOLUTION!!!! SHOULD HAVE braced, through the wall with Bullwire like this, and use ratchets to tighten it up What do you think about these heads, bare in mind, the last piece directly above the opening is not block, just a piece of board to match the block, (has not internal bracing)

-

ICF Foundations +/- 5mm

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

Yeah I don't have any experiences with building but I'm starting to understand that the tolerances in building are fairly wide, we'll see how the rest of it goes up. -

ICF Foundations +/- 5mm

magnethead replied to magnethead's topic in Insulated Concrete Formwork (ICF)

Thanks Lads for your help, in the end, they leveled it without "scabbling" the concrete. (Who knew, they'd take the easy route) They did it purely by shaving the block down at the back. (There was a LOT more shavings then shown in the photo below) He says he gets another change to level too, when he sits the next non-connecting set of walls up,, as the DPC will go over these walls -

Thanks

-

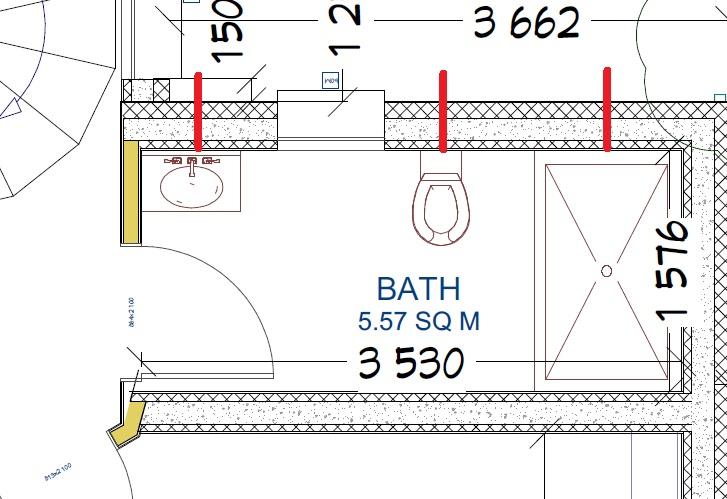

Hi There,I'm putting some sleeves in an ICF wall tomorrow, and I'd like some advice if possible on the way to go with the plumbing here.I have a toilet, sink and shower tray in this bathroom, does it make sense to pipe all these straight out the wall, or connect them to the toilet run in the centre under the structural slab and only feed one pipe out the wall? I would be thinking of making this connection under the slab. See diagram below...... It might just be easier to run them out through the wall though, they would still be underground at this level.What do you think? Thanks

-

How long do you reckon the galvanized steel would last @Vijay

-

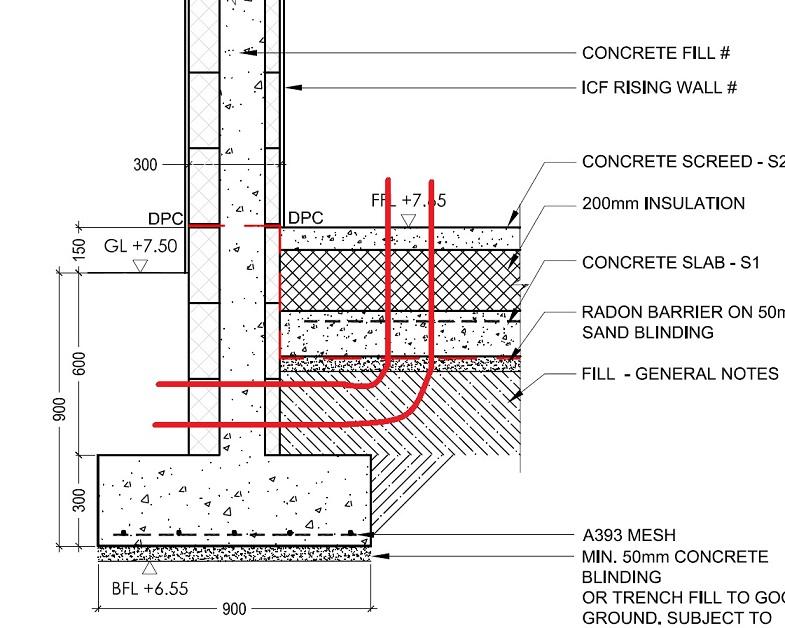

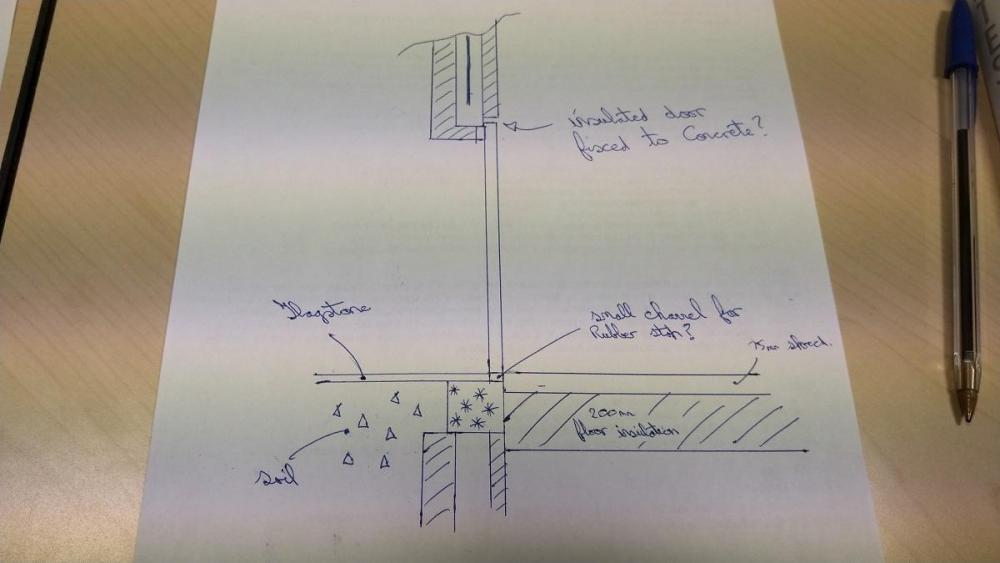

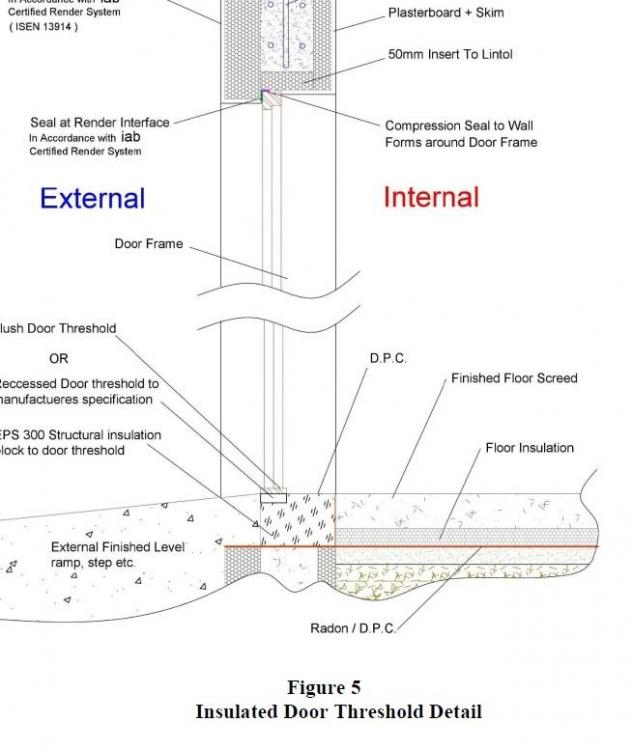

I was thinking the Cold bridge from the Garage skreed would be the worst, I'm loosing heat around the edges obviously...The insulated door company recommended leaving a small channel, 1/2 deep by 1 1/2 inch wide, just to catch any water that might be blown under it....Here's what i'm thinking...Can you see any problems The area with the stars is the structural EPS.

-

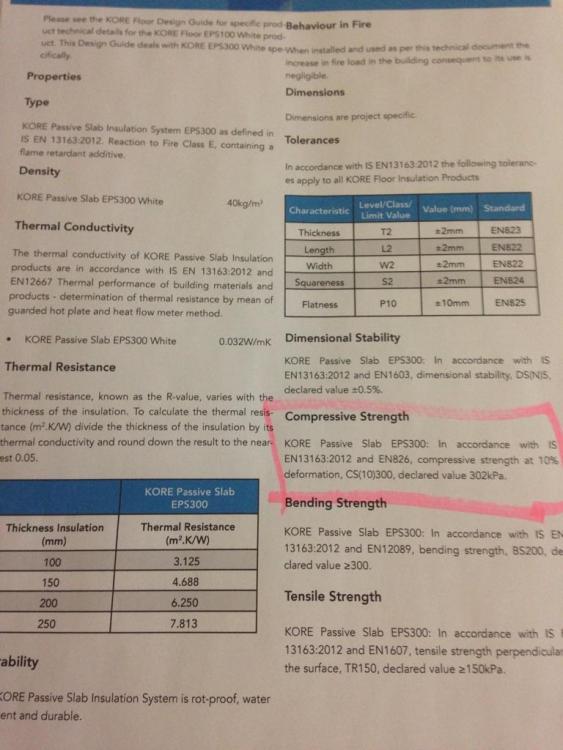

I was looking at this material from Kore, it's coming in at 302kPa which is the same as 302Kn/m2 .... They build houses on top of this stuff, so it might just hold at the threshold, I'm still thinking of a slightly different approach, with a flagstone coming up to the garage door (I'll try and draw it up) Here's the spec sheet for that material

-

I'm pouring the rising walls this Friday thought it was about time to look into some threshold details, Does anyone have an issue with 'Structural EPS' ..Might be a similar block to what the Op mentioned. I hear passive slabs are made of this stuff, but calling EPS structural sounds weird to me, The spec gave 10% deformation at 302kPa which seems fairly good. Here's a detail for an insulated Door, I'm looking at mounting an insulated sectional door for the Integrated garage/workshop (Like above)....Would a detail like this be acceptable across a garage opening? Maybe pushing the block forward, so the Door lip can sit into a 1/2" channel (recommended by the door installer to handle water being blown in)