Wall Build up (Choices)

Still in the Sales cycle for my old house (3rd try!) but while I'm waiting I'll be doing site clearing work next month and I want to take a moment here to make final decisions on my wall build up as this moves the locations of my floor penetrations by 100mm.

Target U Values are as follows:

1. External walls U value = 0.1 W/m2K

2. Sloped Roof U value = 0.1 W/m2k

3. Floor U value = 0.07 W/m2k

This is based on PHPP calculations, they are more strict as my house is quite small, 110m2 and box shaped. This ratio of floor to wall is harder to tick the PHPP boxes so the U values are dropped. Anyway, I'm not going for certification but plan to AIM for these where possible. Back to my wall:

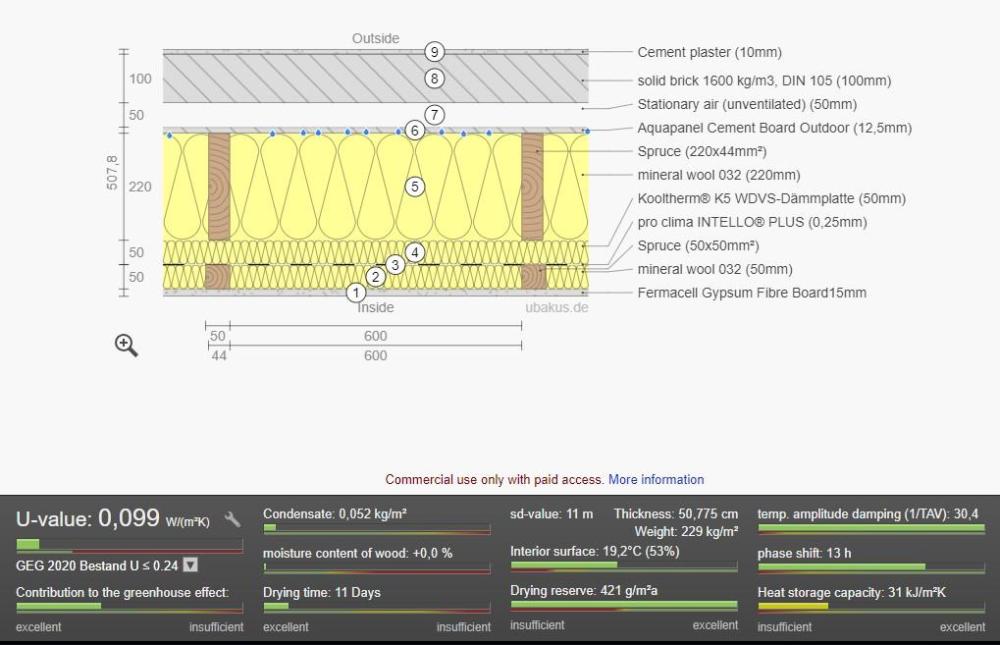

The original Wall used 50mm Kooltherm and an insulated service cavity to meet the U values and save space. I'm not keen on the fact that the Kooltherm isn't breathable so was going to switch it to 100mm Gutex woodfibre board. Then came the question of how to attach the Intello air tightness membrane to Gutex! It would likely require additional framing onto which the Intello membrane is tacked on top of which the service stud work would be added. The Gutex supplier though suggested another product instead of Intello:

https://www.ecologicalbuildingsystems.com/product/superpan-vapourstop

It's a 25kg board. I would fix through this & the Gutex into the 220mm Timber Frame studs to hold everything together. Then use air tightness tape to seal it up.

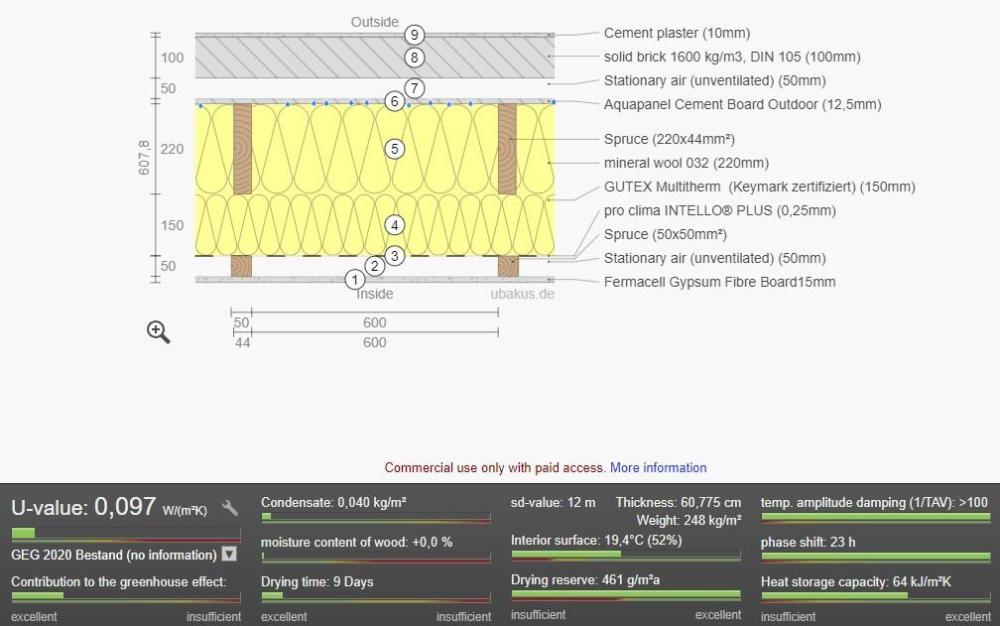

The last question is if I should insulate the service cavity or not? This creates problems for the electrician and requires derating the cable so you use 4mm instead of 2.5mm and 10mm instead of 6mm is my understanding. The cost is one element but trying to route the heavier cable and fix it into back socket connectors & cookers etc must be harder too. The option I'm strongly considering is putting in 150mm Gutex and using that Finsa board, sealing it and then building an uninsulated service cavity onto this. I can pre notch the service batons for future cable runs, I can run standard size cable and any later cables added will be easier to run without fighting the insulation. The downside: I lose an extra 100mm on all outside walls.

I modelled the original Architects plan and my own using the 150mm Gutex and think my own is what I'll go with. The service cavity vs derating cable is the main driver and it's simpler to maintain once built.

The final question is if this approach will work on the vaulted roofs or not. Those 25kg Finsa boards sound heavy. Hanging those, then service batons, then 15mm Fermacell boards and it all hangs off 225/250mm lag screws between the Finsa board, through the Gutex to the 220mm Timberframe sounds like a lot. An option is to fix 100mm Gutex using long screws and washers as per external insulation fixings, then add 50mm batons with 50mm insulation between them. Now I can staple Intello to it and build up the service cavity and add Fermacell. That's my thinking - I'll chat with the supplier about vaulted ceilings and see if they agree. Both wall types are modelled below.

2 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now