Window and Door Detailing on a Stone Clad MBC Timber-framed House

As I've previously discussed we have an MBC Passive Slab and Timber-frame, but unlike most builds, our house also has a very traditional stone cottage-style exterior because the new build sits between our current farmhouse, which dates back over 400 years and a cottage which dates back approaching 200 years, so our planners required that we use the same local quarried stone. So a topic that often comes up is "how do we do the window / door treatment on a timber-framed house with an exterior stone / brick / blockwork skin?" In this blog entry I want to describe how we approached and addressed these issues on our build. Whilst I make no claims about our approach being the only or the best one, Jan and I do believe that this has worked well for us; we are pleased with how it has all turned out and we don't think that we would do it differently if we were doing this all again. So if you are in a similar situation to us, please consider this as one possible approach.

There are a number of issues that we considered in designing our detailing:

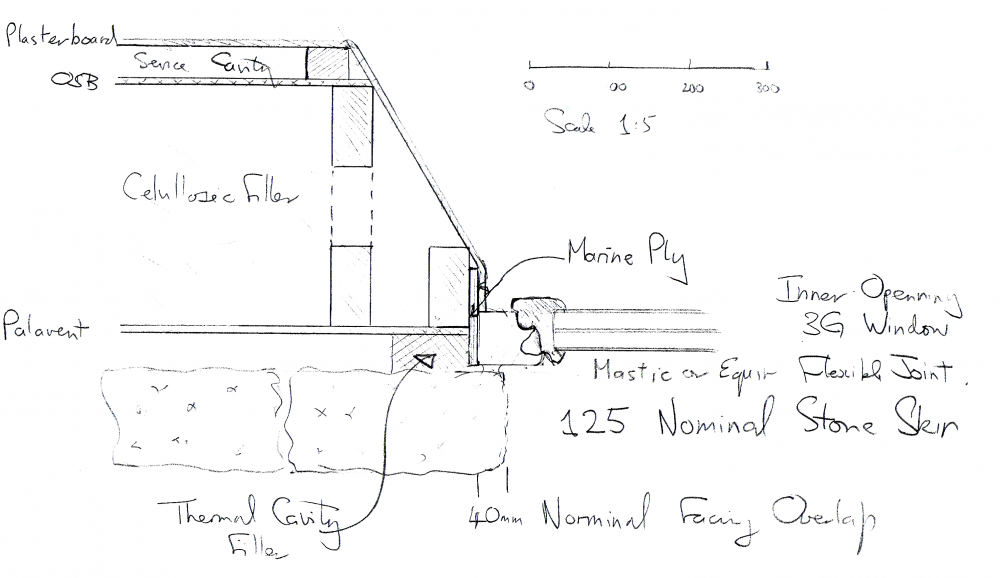

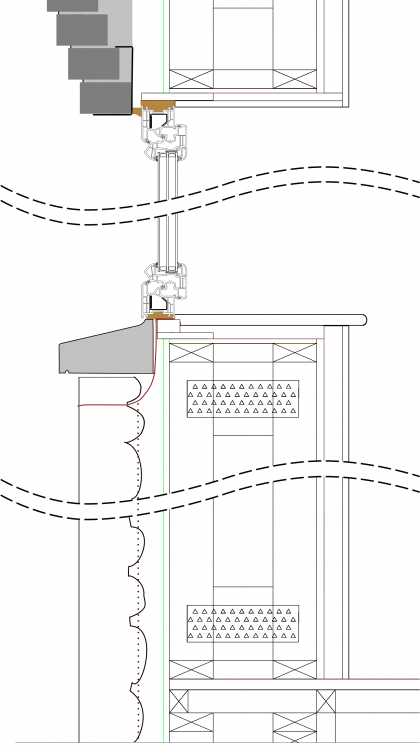

- Decoupling the inner and outer skins. In order to achieve thermal isolation of the inner passive slab, MBC also lays a separate outer ring beam for blockwork, brick and stone skinned houses. The inner slab carries the Larson trusses of the MB twinwall frame, and the outer ring beam carries the stone skin. The inner frame is CLS; the outer stone and mortar, and these two have different expansion characteristics so you should anticipate up to 5mm, say, differential movement between the inner and outer skins. So we decided that we should not use the window and door furniture to couple these.

- Closing the gap. Even so, we still have the issue of the 50mm nominal air gap between the inner and outer skins and how we close this for weather protection and cosmetics. Our solution to thee two points is to move the front of the windows some 45mm forward of the outer surface of the frame. The stonework then sits immediately in front of this,overlapping the window frame by some 30-40mm.

-

Fixing the windows and doors. We have Internorm KF200 Aluclad PVC windows and I agreed a fitting profile with both MBC and ecoHaus SW who supplied the windows. This comprised a box section (something like marine ply would do here) that framed each window opening at the top and sides as follows.

- there was a 10mm filling gap for fixing the windows

- there was a 15mm filling gap at the top ditto

- the windows had to sit hard at the bottom, but I inserted a 44 × 38 tanalised carrier to lift the base above the internal frame base. This was to give adequate clearance to fit the internal cills.

-

Protecting the windows during the build. EcoHaus SW fitted the windows on day 8 of the the frame erection, so by day 9 we had a completely weather-tight and lockable house. The windows had to be in place before erecting the stone skin, and so needed protection from the stone erection process. The solution that we agreed with the ecoHaus technical manager was very simple and extremely effective and one that I would suggest to anyone else doing this. We simply covered the windows in heavy grade clear building polythene, and this served a dual purpose:

- It provided total protection against the muck and dust of stone erection.

- You need a slip surface between the aluminium cladding and the stone skin. (Cf. the first point) The PVC does this. Once the stone skin was complete we simply cut around the PVC on the mortar line. All that is then needed to achieve a total weather seal is to run a thin bead of sealer at the join.

- Minimising any bridging impact. The windows have fire-break socks around them which acts both as insulation and a gap closer. The doors require special treatment. Here prior to slab pour, we had the MBC team cut out 50mm deep slots at the door openings and we placed extra shuttering in to extend these out by some 40mm in front of the outer frame line. These were rebarred and when the slab was poured, these became a 50mm deep concrete tongue that extends out to the front face of the door opening. The doors then sit on a 30mm upstand on these tongues. The upstand acts as a thermal break, but to minimise any bridging through the tongue itself, we used FoamGlass structural bricks to isolate the tongue from the outer cill and the stone skin. If you do the 2D thermal calcs (or at least I did), the thermal capacity of the stone face overlapping the face of the windows materially mitigates the extremes of the temperature variation, and whilst there is a little uplift in the Psi-factors for the window, in absolute terms this equates to adding an extra ½m2 of glass to the house overall, and not enough to cause condensation risks

- Maximising internal light. Our old farmhouse has thick stone walls with window reveals and these work well. So we decided to ask MBC to do a similar treatment in our new build. In short not only do they work, they work brilliantly. They let in perhaps 10-15% more light than deep squared frames and they help open out the rooms. They are an extremely attractive feature and both Jan and I would recommend them to anyone considering using a twinwall frame.

Here is a picture of the slab during the pour. Note the trays for the kitchen French windows and the back door.

Here are a couple diagram extracts showing the window treatment and detailing:

and some photos of the wall in construction showing the set forward windows and the finished effect (less the porch that still has to go in.).

and an internal shot of the kitchen window detail showing the angled reveals:

-

3

3

12 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now