Search the Community

Showing results for tags 'floating floor'.

-

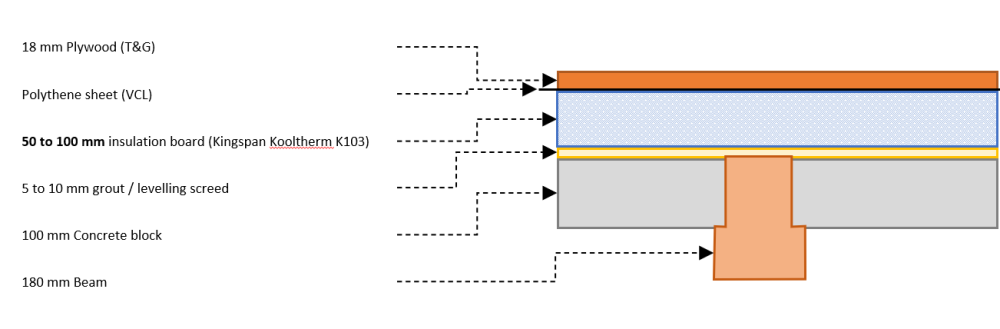

I'm looking for some advice on floating floor construction build up. As part of a renovation project for our ~1990's built home, I want to insulate the ~70 m2 ground floor which is currently of uninsulated beam and block construction with a vented cavity. We are constrained on height of materials that can be added on top of the beam and block, mostly to match existing finished floor level at the bottom of the hallway staircase, but also to avoid shrinking the ceiling height (currently ~2.4 m above finished floor level). So far, it seems like a ply (or other floorboard) sub floor floated on phenolic foam insulation panels will give best combination of thermal resistance, stack height, and cost. We would then add floor coverings, likely all vinyl tile with one room carpeted. I've added a sketch of the proposed build up. I'm looking at using Kingspan K103 which has a compressive strength of 120 kPa at 10% compression. The main questions I have are: Is 18 mm ply going to be rigid enough to avoid deflections / point loads being transferred to the insulation panels? Do we need battens anywhere? So far thinking adding these in doorways, under kitchen units, and for bathroom fittings. IS it necessary to factor in a 6mm ply layer on top as a "sacrificial" covering in case we go with glue down vinyl? Should this be fixed with screws? Interested in thoughts on these points, and anything else I might be missing. If there are any general guides to floating floor construction would appreciate the share.

- 5 replies

-

- kingspan

- floating floor

-

(and 3 more)

Tagged with:

-

Hi everyone, I am looking at buy thing kit to install in my open plan downstairs area. https://underfloorheating1.co.uk/product/premium-xps-lowprofile-kit-50m2 I noticed in the install guide that the XPS panels need to be bonded to the subfloor with a flooring adhesive. I have seen other brands selling similar insulation panels that say this is not required when using using Laminate or Vinyl interlocking flooring on top. What are your thoughts on this, could I get away with out using a glue? Many thanks

- 1 reply

-

- retrofit

- floating floor

-

(and 1 more)

Tagged with:

-

The floor in our property is block & beam, with 2 layers of insulation board on top. Above this is a floating floor of T&G chipboard. The floor finish is solid wood flooring screwed to the floating floor. The difficulty we’re having is draughts from under the skirting board. In addition to radiators we use a log burner for heating, the downside of which is that the log burner draws cold air effectively making the draughts at floor level worse. I’ve tried using both silicone sealant and expanding foam tape to seal the gaps below the skirting boards but because a floating floor moves these haven’t proved effective. Has anyone else had this issue or have thoughts on how I can approach this?

-

When people use overlay board instead of screed what is the best method of heat distribution for an UFH system assuming a build up of approximately 200mm insulation, 22mm Chipboard all bonded together? I'm considering this for our upper ground floor which is on beam and block and has an available depth of 240mm. Site access makes screeding quite challenging and a pumped option isn't within the budget. Further advantages are more depth for insulation and zero drying time but I need to get my head around the UFH components before deciding. Many thanks

- 7 replies

-

- under floor heating

- overlay board

-

(and 1 more)

Tagged with:

-

This is for the Little Brown Bungalow project, but may be more useful here in future for reference. The current floor buildup is, from the bottom: Concrete raft. 300mm or so ventilated void. Suspended wooden floor. Underlay + carpet or similar. The void contains some water and gas pipework. The question how to maintain this access in future. I am planning a 'floating' floor ... though not completely floating. The intended buildup is something like: Concrete raft. Ventilated void. Insulation between joists - 100-200mm rockwool. Suspended wooden floor. Vapour / air membrane 50mm Kingspan between battens. It is from Seconds and Co so the battens are to be safe. 18mm OSB, screwed down to battens. Underlay. Click fit laminate or carpet, depending on room. The question is how to do the floor so that I can get at the gas / water piping if necessary. I am able to adjust the buildup if necessary to a degree. I could potentially leave the battens out altogether or not screw them or the OSB down depending on the Kingspan which I will find out when it arrives, and insert a separation membrane to ease movement. Any comments are most welcome. Cheers Ferdinand

- 16 replies

-

- removaed floor

- maintainable floor

-

(and 1 more)

Tagged with: