Search the Community

Showing results for tags 'cavity insulation'.

-

Evening All, Currently having some work done on my 1970s house, my builder has suggested we could save a significant amount if we were to use a different cavity wall insulation method to that quoted by my architect, for my external walls. Architect has spec'd Kingspan K106 90mm, leaving a 10mm gap (in the 100mm cavity), my builder had initially suggested we could look at Knauf Dritherm 37 100mm instead, though this would end up needing some additional insulation internally (insulated plasterboard) to achieve required U values for building regs. So our builder has suggested we could look at a different type of Knauf, suggesting there are other thicknesses available. I've taken a look at both the Kingspan K106 and Knauf Drithem 37, there is a difference in the thermal conductivity between them, 0.018 (Kingspan) and 0.037(Knauf). As a complete newcomer to insulation types, I'm a bit confused, is there mineral wool out there that can compete with the U value of Kingspan? Also, with the Kingspan, we'd leave a 10mm gap, but with mineral wool it would take the entire 100mm cavity, are there drawbacks to this? What is it that makes Kingspan a superior product? Is it the U value alone, or is there more to it? I'm not sure whether to fork out the additional to keep with the spec, or look for alternative ways to insulate if the saving is in the 000's? Any ideas, guidance or pointing me in the direction of info would be appreciated. I'm sure there are ways to meet regulations using mineral wool, else why would it be available, but I guess i'm trying to understand the points to consider to help guide why one chooses one over the other. Cheers Ant

- 16 replies

-

- phenolic

- mineral wool

-

(and 1 more)

Tagged with:

-

What are others' thoughts on the efficacy of PIR retaining clips. I have anecdotal evidence from someone about them working lose over time thus leading to draughty gap between inner leaf and PIR. My wall build up (just starting) is: 100mm Thermalite, 150 gap with 100 PIR batts, 125 cotswold stone. I will say in advance that I have an excellent blockworker who is a stickler for detailing, knocking snots off, etc. He already beat me to the punch on foil taping all PIR joints (assumed I'd have to nudge on that). I was going to start a convo with him re: sticky foaming the PIR to inner face as they work, as well as the retaining clips on wall ties of course. Overkill? Cheers Tom

- 2 replies

-

- pir

- insulation fixings

-

(and 1 more)

Tagged with:

-

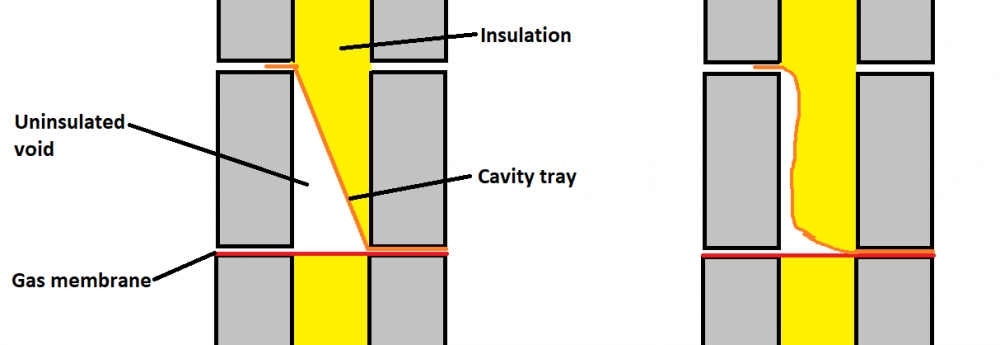

Cavity trays made using DPC roll are often shown simplistically crossing the cavity at an angle from their top on the inner leaf to bottom on the outer leaf. In reality, even if you try to run the DPC material down the inner leaf before crossing the cavity, you will still create a void behind the cavity tray that will end up uninsulated: Is there a way to insulate this void or is it a matter of trying to keep it as small as possible? Preformed corners and stop ends all seem to adopt the shape on the left and so will create quite a significant cold bridge. I'm using blown bead insulation. There is no route for the beads to get between the gas membrane and cavity tray. Also I wouldn't want the pressure of the bead blowing to dislodge the cavity tray.

- 8 replies

-

- cavity insulation

- dpc

-

(and 1 more)

Tagged with:

-

looking for blown cellulose and came across this. would it be an idea to have a section for published building data and product data to allow comparisons https://www.leedsbeckett.ac.uk/as/cebe/projects/stamford/pdfs/del2design.pdf

-

- masonry walls

- window positions

-

(and 2 more)

Tagged with:

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)