SBMS

Members-

Posts

1055 -

Joined

-

Last visited

Recent Profile Visitors

7326 profile views

SBMS's Achievements

Advanced Member (5/5)

220

Reputation

-

Yeah, you’d still be subject to article 4 conditions. I don’t think there’s a specific part of statute relating to ‘when’ PD rights kick in. As it was explained to me PD rights apply to a ‘dwelling house’. I don’t believe there’s any single definition of a dwelling house but the planning consultant explained there’s a common law test that refers ‘To capability of occupation’. This is a ‘matter of fact based on the probabilities’. In actual fact this is what councils use to pre-assign valuation bandings to prevent delays in council tax registration, where builders defer completion certificates to prevent council tax. It works both ways in this sense. Fundamentally my take away is that there is no single point in time or concrete certified point at which a building acquires PD rights except for the above definitions of dwelling house.. If anyone can cite planning law that states a ‘completion certificate’ must be present for PD rights to come into effect I’d be interested…

-

It’s the definition of ‘complete’ - As my planning consultant explained In law permitted development rights are granted when the building is ‘Completed and capable of occupation as a dwelling house’ meaning that the building has reached a stage of physical construction where, as a matter of fact and degree, it is ready and capable of being beneficially used as a home for its intended purpose. Relevant case law here is well trodden and is actually the reason why councils often rate a building for council tax as capable of habitation prior to a completion certificate being issued. The single line my consultant explained was whether it was ‘capable of occupation’. Building regs or completion certificate is irrelevant, it’s the state of the building on the ground that matters.

-

Not quite true… PD rights exist when house is substantially complete. It doesn’t need to be signed off. I think if your gates are above 1m in height (when next to a road) you need planning otherwise they are PD.

-

Vehicle Presence Detection with Loxone

SBMS replied to SBMS's topic in Networks, AV, Security & Automation

I don’t in particular. But if my gate pulse sensor is connected to a loxone relay I might as well connect the wire loop into it as well seeing as I have a loxone intercom controlling ingress? I think a wire loop sounds like the way to go 👍 -

Am building my own automation system for our gates using Loxone. Has anyone managed to get a reliable way to detect vehicle approaching a gate (this is internally so no authorisation required so vehicles can leave), using standard loxone sensors? I know traditional gate systems have a sensor in drive way that detects a vehicle driving over it to allow people to leave, wondered if there was the same for Loxone?

-

How much is it to add to the build? we’ve just finished doing it ourselves. Probably overkill because we are planning on aerobarrier as well… but it’s one thing that wasn’t expensive in materials but was time consuming. Soudatight membrane with fleece over all cavity closing joints and then airtight tape on window to cavity junction.

-

We are using Panasonic aquarea with the air smart fan coil units. Not installing myself. I did a rough design myself and Panasonic then did a full design.

-

Yes it’s all fine. We had ours done just before Christmas. We used airtight osb board. Installers cut a hole, pumped, replaced hole and taped with a pro clima patch. Most were okay but i went round and taped the edges anyway this weekend ( took me a day).

-

Does aerobarrier negate need for airtightness detailing?

SBMS replied to SBMS's topic in Ventilation

Is that pre-skim? Do you mind me asking how much they charged (per sqm?) -

Fabric and ventilation heat loss calculator

SBMS replied to Jeremy Harris's topic in Heat Insulation

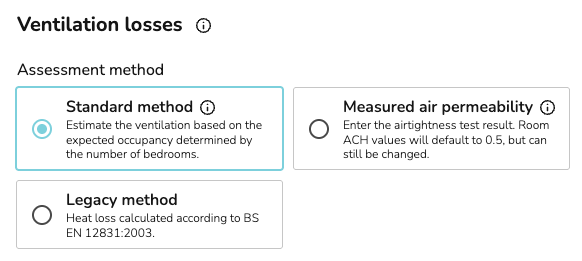

Agreed, you need the input data (fabric data etc) to be correct - but the same is said for Jeremy's tool. From what I've seen the modelling software for MCS new versions is more accurate as it accounts for PSI values. The newer MCS standard also allows specifically for an Air permeability input (the below is Heatpunk's): There's a good guide that explains this: https://help.heatpunk.co.uk/books/heat-pump-task-and-system-performance/page/ventilation-calculations-in-heatpunk- 204 replies

-

- heat loss

- ventilation

-

(and 4 more)

Tagged with:

-

I ask because you said ‘my structural deck is IN the insulation’. It’s not. It’s above it. And in a warm roof it’d be under it.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

Where do you think your structural deck is in your makeup?

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

Fabric and ventilation heat loss calculator

SBMS replied to Jeremy Harris's topic in Heat Insulation

I’d spend £300 on independent ‘MCS accredited’ heat loss and take that that to umbrella company for heat pump sizing. You’ll get the 300 back and then some if you get the grant! Prob end up nearly free.- 204 replies

-

- heat loss

- ventilation

-

(and 4 more)

Tagged with:

-

Let’s be super clear. It absolutely is a cold roof because your structural deck is on the cold side of the insulation. That’s the definition of a cold roof. You almost certainly cannot negate airborne moisture getting through. No matter how well you detail you will have 1mm gaps all over - eventually. Even if you detail it right on day one your timber will shrink and gaps will open up. So it’s not a ‘expert detail your way out of it’. like I said - If you have building regs on your build this is academic. You won’t pass with an unventilated cold roof. Why don’t you just ventilate it if you’re restricted in height? Not ideal or robust for flat roofs though…

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with:

-

Moisture gets through (diffuses) through all the imperfections I listed above. Your makeup is on a knife edge. Take the 25mm down to 1mm and it’ll still show as no condensation likely. Remove one or both those layers and you’ll see condensation. The 25mm isn’t magic. It’s only magic in ubakus because it models It as one homogeneous entirely diffusion proof layer. I don’t think it models air movement, only diffusion.

- 77 replies

-

- flat roof

- condensation

-

(and 2 more)

Tagged with: