hotnuts21

Members-

Posts

72 -

Joined

-

Last visited

About hotnuts21

- Birthday May 28

Personal Information

-

Location

Aberystwyth

Recent Profile Visitors

4004 profile views

hotnuts21's Achievements

Member (3/5)

2

Reputation

-

Hot water boost error daikin.

hotnuts21 replied to hotnuts21's topic in Air Source Heat Pumps (ASHP)

All back to normal thanks everyone. -

Hot water boost error daikin.

hotnuts21 replied to hotnuts21's topic in Air Source Heat Pumps (ASHP)

Whole unit as in heat pump etc too or just the HW tank and controller? I have suggested they do a "power cycle" but will call over Tomo and see if I can help. Apart from flicking the isolator switches off is there another way to turn it off I might be missing? -

Hot water boost error daikin.

hotnuts21 replied to hotnuts21's topic in Air Source Heat Pumps (ASHP)

@ProDave that's what the support said to do, so they have tried that and the one one on the left clicked, but the warning error is still flashing on the panel and hasn't cleared. Which I think is why they are confused. @JohnMoI have no idea, I was hoping to learn from it, but think it's a bit of a bodge. Turns out it's the same builders who did the MVHR install bodge on another friends house. I presume normally there's some kind of heat exchanger in the tank that uses the hp water to heat the water in the tank? -

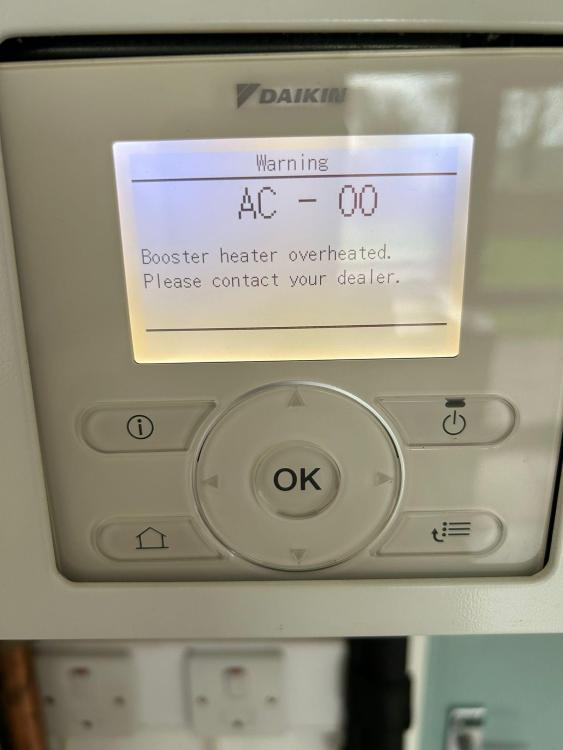

We had a power cut the other day and since then a neighbours setup (which I've been exploring for my own needs) has been flashing this error. They have been onto supplier but the supports been a bit patchy. They were told to press the red reset buttons in the boiler panel and they've shut it all down and restarted it but error still flashing. Just wondering if anyone has any idea of something else they can try Tomo? It seems the hot water isn't heating up as well (makes sense) support is taking 24-hrs before an engineer gets in touch each time they phone.

-

MVHR help water in pipes!

hotnuts21 replied to hotnuts21's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I also have to say I'm quite impressed that the black tape holding the inlet up and to the rafters has lasted that long 😄 But having another look at the condensate pipe run, im wondering why it seems to be going in the opposite direction to the soil vent and rather right to the eaves... -

MVHR help water in pipes!

hotnuts21 replied to hotnuts21's topic in Mechanical Ventilation with Heat Recovery (MVHR)

HI all, thanks for the great responses, I've summarised the main points and responses below and added some more information. The builder was a bodger, I think he threw all new tech at the house without knowing what it was. The ASHP for example has had a load of issues and didn't have a magnetic filter on the system and was constantly running at full whack until someone from Daiken sorted it. So this is another chuck it in and see I think, although its been working pretty well for 8-10 years. Apparently up until about 18 months ago it was rattling because the fan speed was constantly on max, an electrician turned it down and she thinks that when the leak might have started took a while to notice the damp patch in the corner. 1, the orientation of pipes, etc! - I think this is a trick of the camera and the angles she took the photos in with the loft etc, the drain seems to run parallel to the floor/roof joists so I'm pretty sure it's running straight, but I'm hoping to get in there and have a look this weekend. 2, Cause - So it seems we think the water building up is just warm air coming up through the ducts, into the pipes, and condensing because the units not on. 3, Clear the water from the pipe(no idea how but I'll give it a go, just disconnect from the machine and manipulate it through the pipe to a bucket) and put the unit back on for now, but put a bucket under the faulty drain to collect the leak that started all this. I will also open the machine and see whats going on inside if the condensate is blocked etc. 4, Look at fitting/fixing the drain as in the interim. 5, Look at getting someone in to redo the pipework at least in the loft who knows what they are doing. The local heating and engineers company that has looked at it and drained the hoses before Christmas just said it needed replacing and couldn't be fixed, but I've asked her to get a written reason why so I can see if they even realized the pipes were wrong, maybe they were talking about the pipes, etc only. But im not convinced anyone locally fully understands MVHR with conversations I have had recently with plumbers and sparks. Ill keep looking though. 6, She has changed the filters several times. The silver pipes are the correct type? Is it just the outgoing white pipe (I hope it's the outgoing) that needs better lagging and placement? Oh, and the grey pipe is I think the Soil pipe, but no idea why it's running flush with the roof angle. She told me she has 3 vents on the roof so I'm guessing two for MVHR and one for the soil pipe. But I'll try and get some more pics. -

MVHR help water in pipes!

hotnuts21 replied to hotnuts21's topic in Mechanical Ventilation with Heat Recovery (MVHR)

This is/was the waste/condensate pipe that's been leaking and started the problems. Installed like this 🤮 -

A friend of mine has a newish house (10yrs ish old) and it's has a cheap MVHR unit in the loft. It's been ok, although its leaked a few times. About a month ago she was told a leak she'd noticed on the bedroom ceiling was coming from the small 'waste/condensate? pipe at the bottom which had been bodged with so much mastic the replacement parts weren't available and what they (local heating company) could get didn't and wouldn't fit. So she was advised to switch it off. She went into the loft this week and the small white pipe which goes up to a roof vent is full of water and dropping in places. I'm gonna go and hopefully help her drain them, whilst waiting for the quote for a new unit. Any tips on how greatfully received However, what I can't understand is where is the water coming from in the pipes? Why is so much building up with the unit off? I'm still looking to install my own unit, so all possibilities are a good learning experience too. Some photos below and wow my first though was mega bodge and amazed it lasted 10yrs.

-

Dwg editor online or service?

hotnuts21 replied to hotnuts21's topic in New House & Self Build Design

Cheers for the guidance all 🙂 i think it's in hand now 🙂 -

Hope this is the right forum, I need to make changes to our architects dwg drawing. We had them done about 4 yrs ago and we are doing some minor changes I want to update to pass to trades. Any suggestions for online tools or services, I'm happy to pay to have them modified. It's only 2D and basically moving a door, and WC room from one end of the extension to the other and adding a pantry room. Any suggestions greatly received, everything I've tried just doesn't seem to want to work (prob my uselessness). Thanks Paul

-

Thanks for the help, a few sleepless nights getting ready for everyone and two nights of taking way too long to get everything down, the disadvantage of old houses nothing is square!! Anyway from the photo at the start, to fiinally finished floor. Thanks 🙂 I presume I can just trim all the edge insulation, upstand and polythene to floor level when its nicely hardened off?

-

Don't need the solvent weld under the screed? I'm concerned if the rubber fails it's gone!

-

Just noticed this on the scrap pile from when we demolished the rear. Could cut this down and slide it into the bend so the boss is almost at floor level? Seems it needs a 63/5mm reducer?

-

Solvent weld boss strap might work if i can find one locally?

-

The collar just above the concrete is the top of a rest bend, and yeah I just found out I can pull the top part out 😆. Although its going to be a lot of hassle cutting into the insulation, I think a straight run is best. The pipe going into the top is the temp kitchen waste I can play with that temporarily. Ive just realised that none of the standard push in boss pipes have a solvent weld attachment except the one that goes over a pipe, and thats going to cause issues.